Waste heat comprehensive utilization system for rotary kiln

A rotary kiln and waste heat technology, which is applied in the direction of rotary drum furnace, waste heat treatment, lighting and heating equipment, etc., can solve the problems of the influence of the heat dissipation capacity of the rotary kiln and the adjustment of the amount of waste heat that cannot be recovered, so as to improve the heat dissipation efficiency and improve the Effects of heat dissipation performance, increased length, and heat-absorbing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

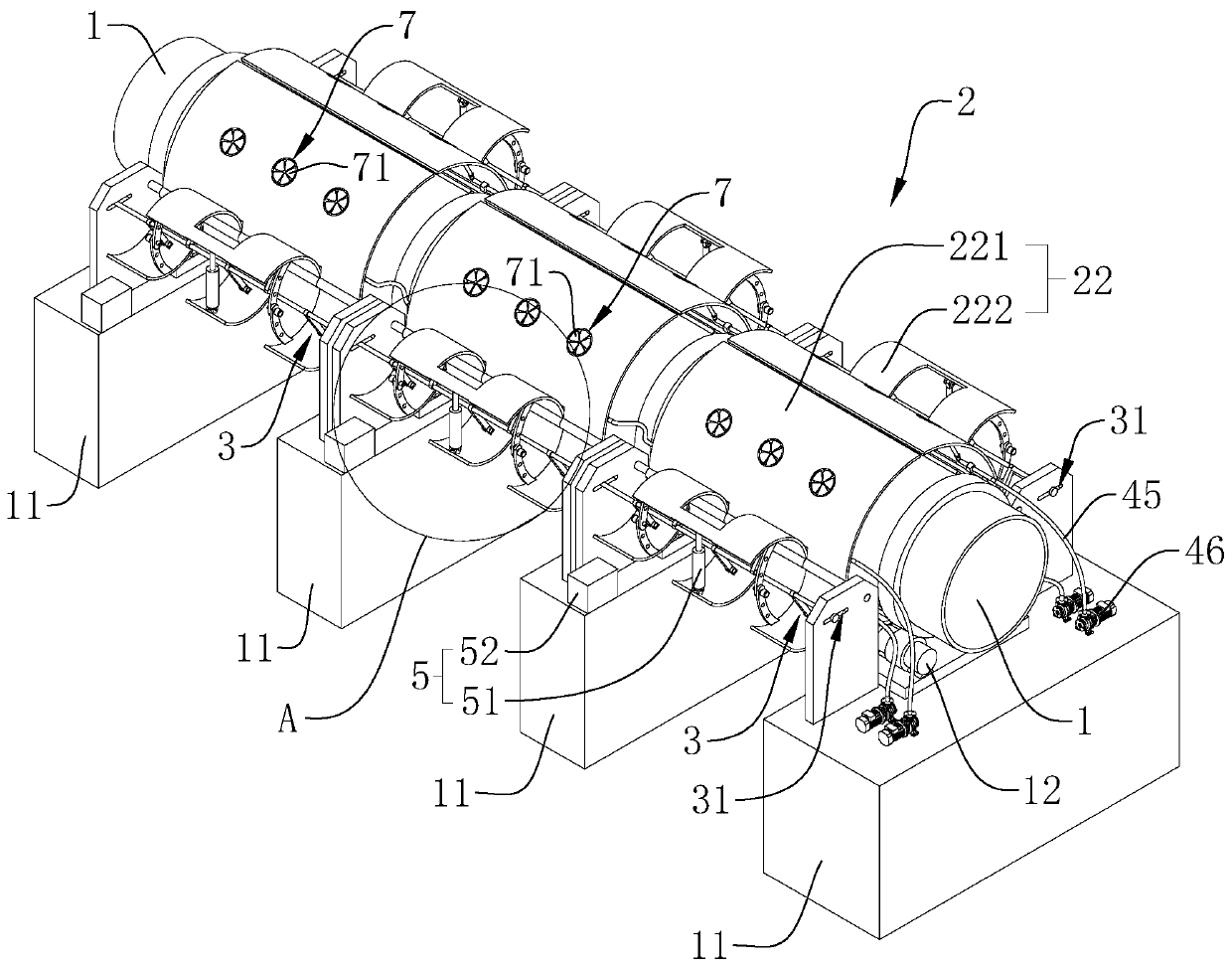

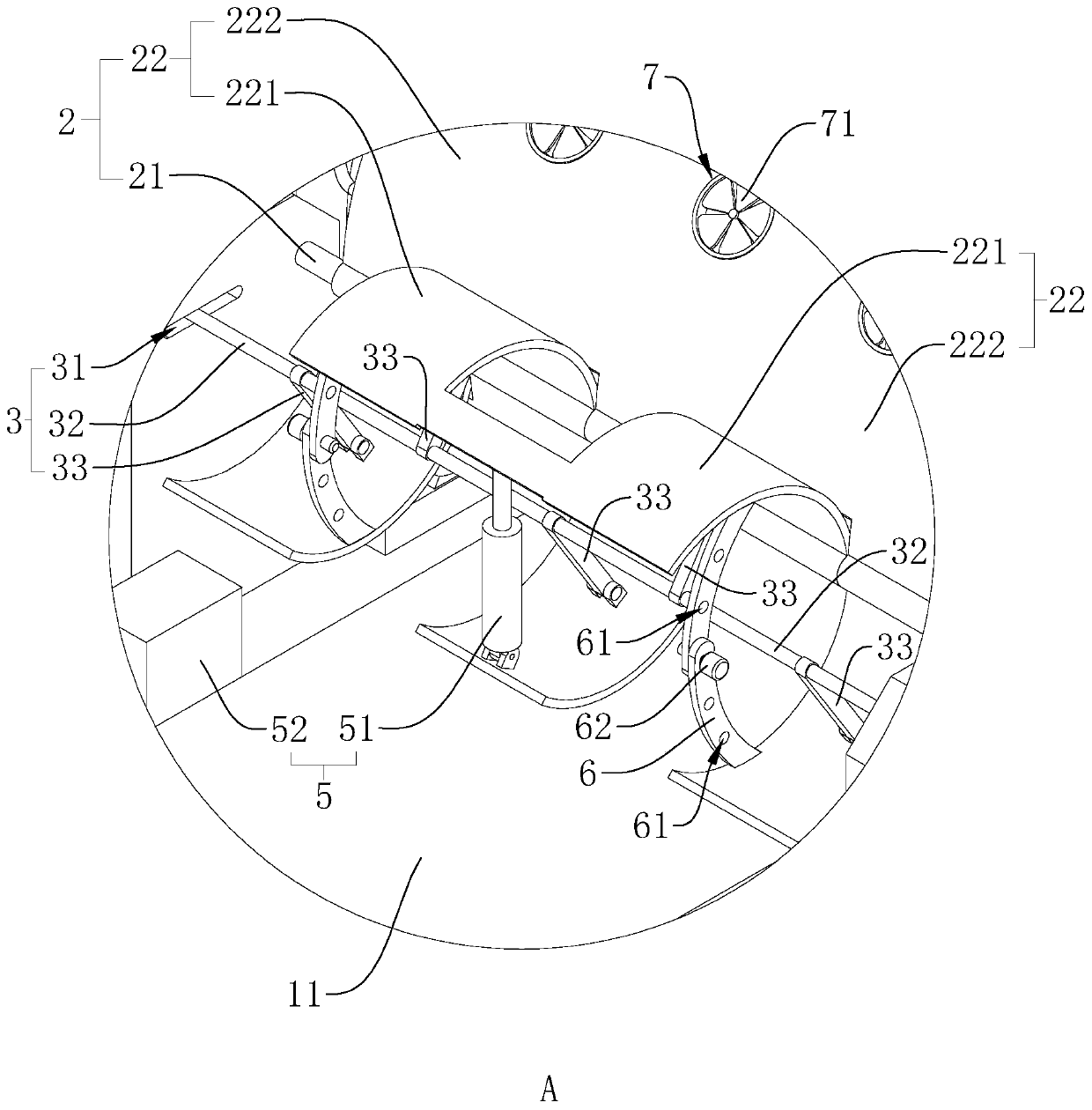

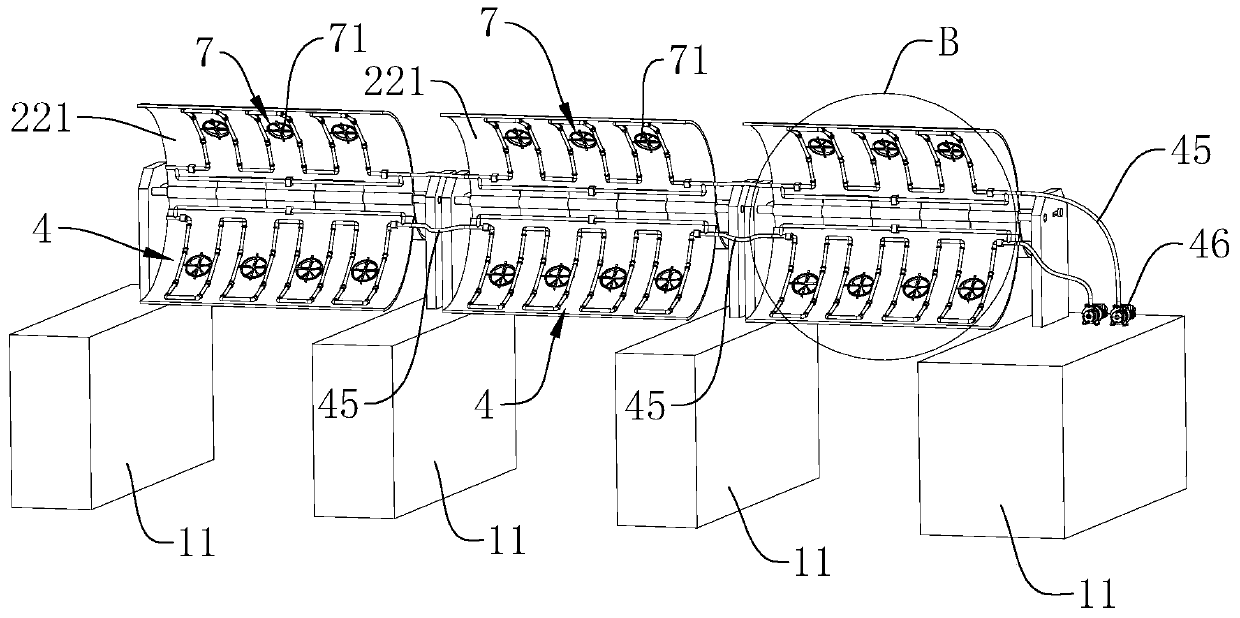

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] refer to figure 1 and figure 2 , is a rotary kiln waste heat comprehensive utilization system disclosed in the present invention, which includes a plurality of support piers 11 for supporting the rotary kiln shell 1, and also includes a heat collection mechanism 2 for absorbing the waste heat on the outer wall of the rotary kiln shell 1. The thermal mechanism 2 is connected to the load that needs to use hot water; each support pier 11 is provided with a supporting wheel mechanism 12 for supporting the rotary kiln shell 1, and the single-section rotary kiln shell 1 is supported on two adjacent support piers 11 on the two sets of tugboat mechanisms; the heat collecting mechanism 2 includes a support shaft 21 that is rotatably supported between two adjacent support piers 11, and each side of the rotary kiln shell 1 is respectively provided with a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com