Pavement super-tough wearing layer and hot paving process thereof

A wear layer and super-tough technology, applied in the field of super-tough wear layer on road surface and its hot paving technology, can solve the problems of difficult maintenance, unsatisfactory economic and social benefits, insufficient bond strength, etc., and achieve bond strength and resistance The shear strength is improved, which is conducive to large-scale promotion and implementation, and the effect of super strong anti-reflection crack performance

Pending Publication Date: 2020-07-10

广州方华交通技术有限公司

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, many cement pavements were built in my country in the early stage. Due to the defects of difficult maintenance, poor comfort, safety and aesthetics of cement pavements, many cement pavements have been or need to be transformed from "white to black". It can be applied to asphalt pavement maintenance and cement pavement "white to black" ultra-thin overlay. This ultra-thin overlay should be able to form a super-strong bond with the old pavement. The wear layer should have super crack resistance and good wear resistance. Anti-slip, anti-water damage, high-temperature stability, and should also have the characteristics of driving comfort, safety, durability, and low noise

[0003] At present, the asphalt pavement maintenance overlay and the "white to black" technology that have been widely used in China have micro-surfacing. The bonding strength between the traditional micro-surfacing and the old pavement is insufficient, and it is easy to fall off, fast attenuation, poor durability, and surface bone. However, although the ultra-thin wear layer technology in the prior art can overcome some of the defects of the micro-surfacing technology, it can be changed from white to black on asphalt pavement or cement pavement with severe cracks. "Reflective cracks are easy to occur when covering the surface. The cracking will weaken the waterproof function of the covering layer, affecting the durability and aesthetics. Because the ultra-thin wearing layer adopts open gradation, the void ratio is large, and the cement pavement or bridge surface is "white to black". When overlaying, the adhesion between the overlay and the old cement pavement is poor, and it is easy to fall off

In addition, the ultra-thin wear layer needs a special synchronous asphalt paver for synchronous spraying of emulsified asphalt sticky layer oil. The cost of paving equipment is high, the investment is large, and the economic and social benefits are not ideal.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

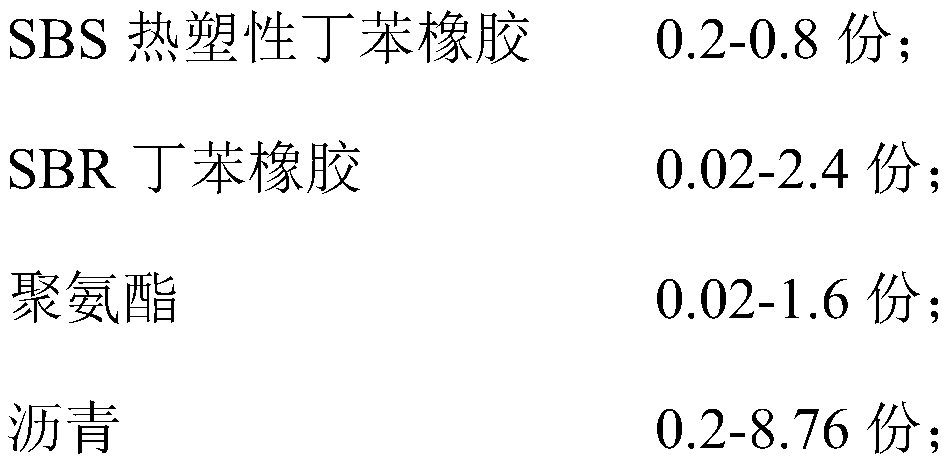

[0088] A pavement super-tough wear layer, comprising a bonding underlayer and an abrasion top layer; the components of the bonding underlayer are as shown in Table 1 in parts by weight:

[0089] Table 1 Example 1-4 Components of Bonding Lower Layer and Wearing Upper Layer

[0090]

[0091]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a pavement super-tough wearing layer and a hot paving process thereof. The pavement super-tough wearing layer comprises a bonding lower layer and a wearing upper layer. The bonding lower layer comprises the following components, by weight: 40 to 50 parts of asphalt, 30 to 60 parts of xylene, 2 to 15 parts of acrylic resin, 2 to 15 parts of polyurethane, and 2 to 8 parts ofSBS thermoplastic styrene-butadiene rubber; the wearing upper layer comprises the following components, by weight: 80 to 110 parts of aggregate, 5 to 9 parts of high-toughness and high-elasticity composite modified asphalt, and 3 to 6 parts of mineral powder. Besides, the hot paving process of the pavement super-tough wearing layer comprises a paving step of a bonding lower layer and a paving stepof a wearing upper layer. After improvement of the components of the bonding lower layer and the wearing upper layer, the pavement has super-strong reflection crack resistance, low-temperature cracking resistance and fatigue cracking resistance.

Description

technical field [0001] The invention relates to a pavement super-tough wearing layer and a hot paving process thereof, belonging to the technical field of pavement construction. Background technique [0002] Asphalt pavement has the advantages of driving safety, comfort, and convenient maintenance. At present, more than 85% of new high-grade highways in my country use asphalt pavement. Under the long-term effect of natural environment and vehicle load, asphalt pavement will gradually show phenomena such as cracking, rutting, insufficient skid resistance, looseness, aging and pitting. If it is not repaired in time, the disease will further accelerate and deteriorate. On the one hand, it will affect the pavement The overall service life of the asphalt pavement accelerates the arrival of major and medium repairs on the pavement; on the other hand, it will affect the safety, comfort and aesthetics of driving. . In addition, many cement pavements were built in my country in the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E01C7/35C04B26/26C09J195/00C09J133/00C09J175/04C09J153/02C08L95/00C08L53/02C08L9/06C08L75/04C04B111/20C04B111/27C04B111/52

CPCC04B26/26C04B2111/00362C04B2111/00612C04B2111/0075C04B2111/20C04B2111/27C04B2111/52C08L95/00C08L2205/035C09J195/00E01C7/35C04B14/14C04B14/28C04B24/2676C04B24/282C08L33/00C08L75/04C08L53/02C08L9/06

Inventor 胡学斌于泳潭邓英文

Owner 广州方华交通技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com