Ti2AlNb alloy and preparation method of Ti2AlNb alloy bar

An alloy and bar technology, applied in the field of Ti-Al intermetallic compounds, can solve the problems of long-term creep performance at high temperature, unfavorable oxidation resistance, unfavorable creep performance, etc., and achieve good solid solution strengthening effect, weakening Forged texture, the effect of reducing surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

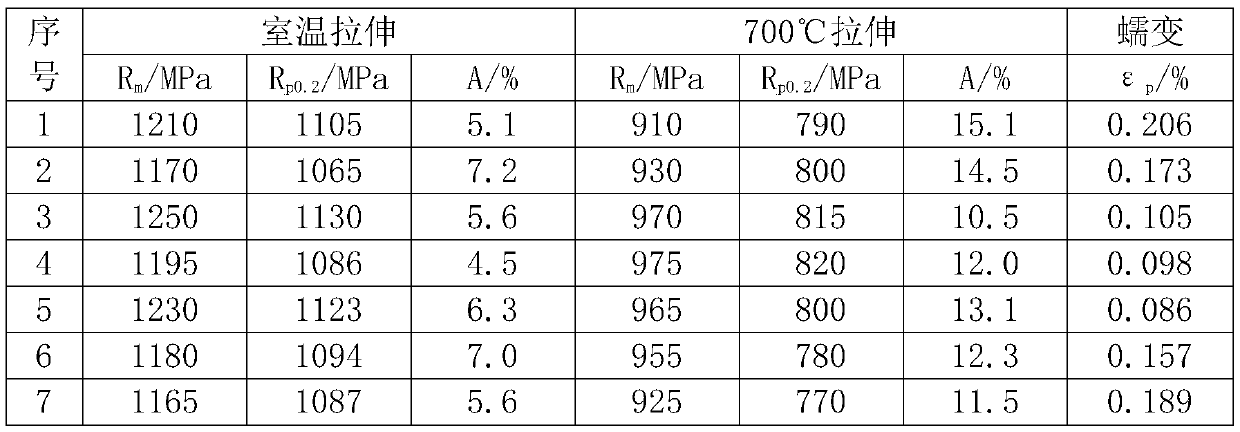

[0026] Table 1 for Ti 2 AlNb alloy 7 kinds of metal components and their atomic percentage content,

[0027] Table 1 Ti 2 Composition of AlNb alloy ingot

[0028] serial number Composition, atomic percent 1 Ti-24Al-20Nb-0.5W-1Zr 2 Ti-23Al-20Nb-1W-1Zr 3 Ti-22Al-20Nb-2W-1Zr 4 Ti-23Al-20Nb-2W-1Zr-0.5Si 5 Ti-23Al-20Nb-1W-1Zr-1Hf 6 Ti-23Al-20Nb-1W-1Zr-1Ta 7 Ti-23Al-20Nb-1W-1Zr-1Mo

[0029] The steps of the method for preparing Ti2AlNb alloy rods in Table 1 are as follows:

[0030] ① A 100kg ingot of Ti2AlNb alloy was prepared by 3 times of vacuum consumable melting process. The atomic percentage of the chemical composition of the ingot is shown in Table 1. The ingot was turned and skinned, and the riser and bottom pad were cut off. The finished ingot specification was

[0031] ②The surface of the ingot is coated with anti-oxidation paint, and then heated and kept at 1120°C for 65 minutes. After reaching the holding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com