Mask all-plastic nose bridge strip polyolefin modified material and preparation method thereof

A modified material, polyolefin technology, applied in protective clothing, clothing, clothing, etc., can solve the problems of difficult separation of polyolefin polymer materials, unfavorable separation and recycling of waste masks, and high requirements for softness and hardness of iron wire, etc., to achieve high The effect of cost performance, convenience, recyclability, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

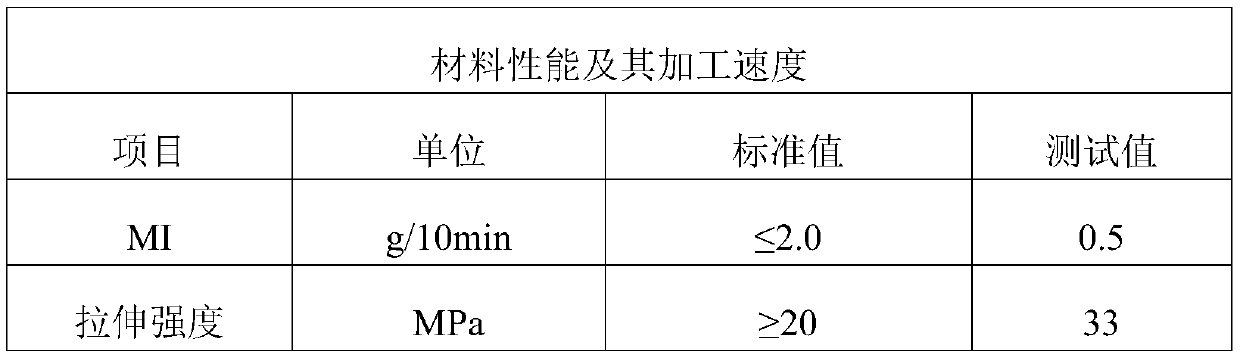

Embodiment 1

[0030] The polyolefin modified material of the all-plastic nose bridge strip of the mask provided in this embodiment includes the following raw materials in parts by weight: 60 parts of polyethylene, 5 parts of polypropylene, 2 parts of softening agent, 15 parts of fiber, and 1 part of anti-aging agent 1 part, 1 part of lubricating dispersant, 8 parts of talcum powder, 1.5 parts of processing aid, 1.5 parts of coupling agent, 5 parts of compatibilizer, wherein, polyethylene is high-density polyethylene, and the manufacturer and brand are Sinopec 5200B; The agent is ethylene-octene copolymer, the manufacturer and brand is Dow 8100; the polypropylene is random polypropylene, the manufacturer and brand is Exxon Mobil APP299; the fiber is 6mm alkali-free chopped glass fiber; the anti-aging agent is A mixture of hindered phenolic antioxidants (brand name GA80), phosphite antioxidants (brand name HP10), and thioester antioxidants (brand name DSDTP) in a weight ratio of 4:3:3; process...

Embodiment 2

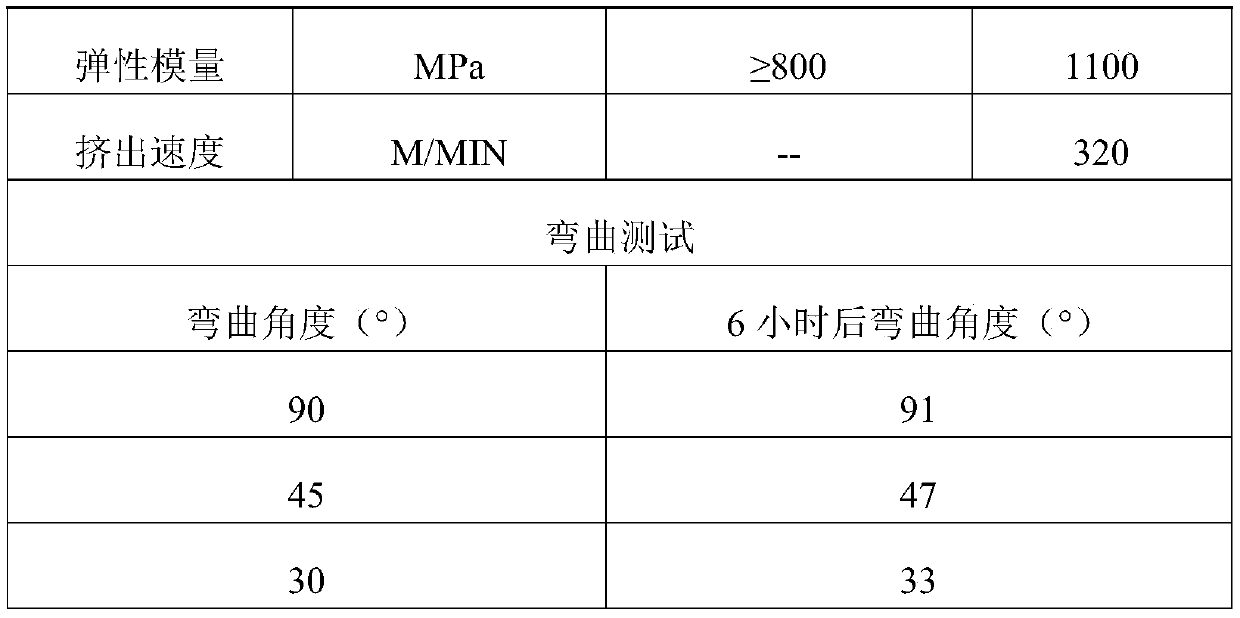

[0040] The mask all-plastic nose strip polyolefin modified material provided in this embodiment comprises the following raw materials in parts by weight: 52 parts of polyethylene, 5 parts of polypropylene, 2 parts of softening agent, 20 parts of fiber, 1 part of anti-aging agent 1 part, 1 part of lubricating dispersant, 10 parts of talcum powder, 1.5 parts of processing aid, 1.5 parts of coupling agent, 6 parts of compatibilizer, wherein, polyethylene is high-density polyethylene, and the manufacturer and brand are Sinopec 5200B; The agent is ethylene-octene copolymer, the manufacturer and brand is Dow 8100; the polypropylene is random polypropylene, the manufacturer and brand is Exxon Mobil APP299; the fiber is 6mm alkali-free chopped glass fiber; the anti-aging agent is A mixture of hindered phenolic antioxidants (brand name GA80), phosphite antioxidants (brand name HP10), and thioester antioxidants (brand name DSDTP) in a weight ratio of 4:3:3; processed The auxiliary agent...

Embodiment 3

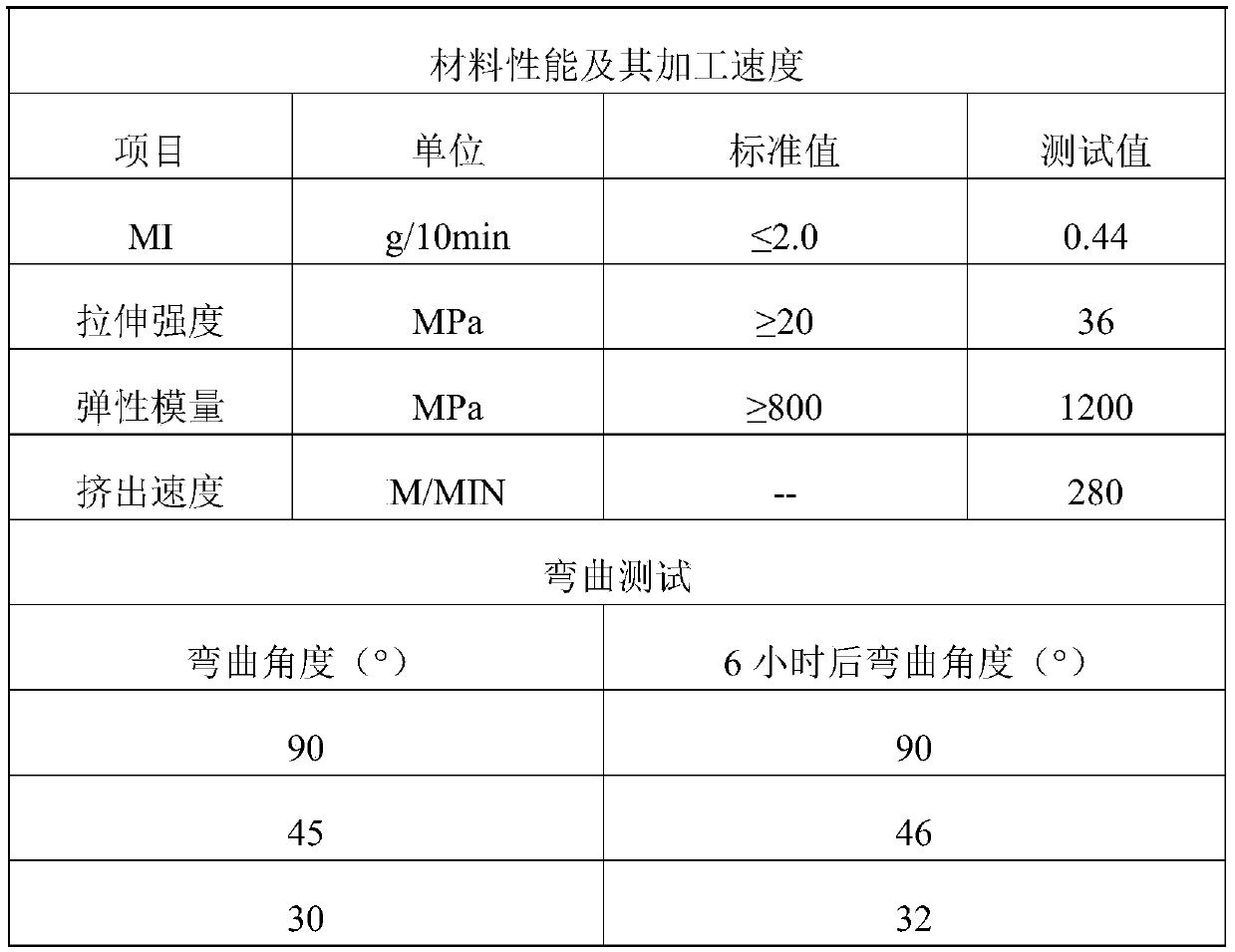

[0049] The polyolefin modified material of the all-plastic nose bridge strip of the mask provided in this embodiment comprises the following raw materials in parts by weight: 40 parts of polyethylene, 10 parts of polypropylene, 3 parts of softening agent, 20 parts of fiber, 2 parts of antiaging agent 1 part, 1 part of lubricating dispersant, 10 parts of talcum powder, 2 parts of processing aid, 2 parts of coupling agent, 10 parts of compatibilizer, wherein, polyethylene is high-density polyethylene, and the manufacturer and brand are Sinopec 5200B; The agent is ethylene-octene copolymer, the manufacturer and brand is Dow 8100; the polypropylene is random polypropylene, the manufacturer and brand is Exxon Mobil APP299; the fiber is 6mm alkali-free chopped glass fiber; the anti-aging agent is A mixture of hindered phenolic antioxidants (brand name GA80), phosphite antioxidants (brand name HP10), and thioester antioxidants (brand name DSDTP) in a weight ratio of 4:3:3; processed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com