Preparation method of food-grade polyacrylamide

A polyacrylamide and acrylamide technology, applied in the field of functional polymers, can solve the problems of backward production technology and excessive acrylamide monomer content, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

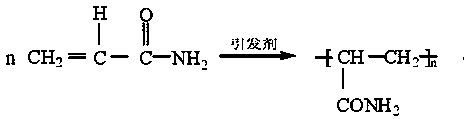

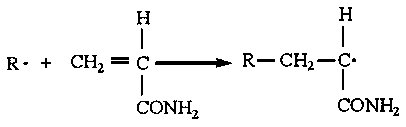

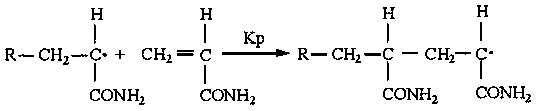

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of food-grade polyacrylamide

[0040] Accurately weigh acrylamide, prepare an acrylamide solution with a concentration of 23wt% with deionized water, add sodium metasulfite and sodium acrylate with a total mass of 0.1% of the reactants, the mass ratio of sodium acrylate and acrylamide monomer is 1:3, and use 30wt% NaOH solution was poured into the reactor after adjusting the pH to 7. The reactor was placed in a constant temperature water bath for constant temperature (initial temperature 7° C.) and nitrogen was blown for 30 minutes. Add 0.2% modified silicone (3-aminopropyltriethoxysilane KH550) to the total mass of the reactants, and then add the corresponding initiator system reagents (chain transfer agent and redox agent): the added chain transfer amount is the reactant 0.03% of the total mass, the addition of redox agent is 40% of the total mass of reactants (potassium persulfate is the oxidizing agent, sodium bisulfite is the reducing agent, the ma...

Embodiment 2

[0044] (1) Preparation of food-grade polyacrylamide

[0045] Accurately weigh acrylamide, prepare an acrylamide solution with a concentration of 23wt% with deionized water, add sodium metasulfite and sodium acrylate with a total mass of 0.15% of the reactants, the mass ratio of sodium acrylate and acrylamide monomer is 1:2, and use 30wt% NaOH solution was poured into the reactor after adjusting the pH to 8. The reactor was placed in a constant temperature water bath to maintain a constant temperature (initial temperature 9° C.) and nitrogen was blown for 30 minutes. Add 0.2% of the total mass of the reactant modified silicone (3-aminopropyltriethoxysilane KH550), and then add the corresponding initiator system agent: the added chain transfer dose is 0.01% of the total mass of the reactant, redox The dosage of the reagent is 40% of the total mass of the reactants (potassium persulfate is the oxidizing agent, sodium bisulfite is the reducing agent, and the mass ratio of the oxi...

Embodiment 3

[0049] (1) Preparation of food-grade polyacrylamide

[0050] Accurately weigh acrylamide, prepare an acrylamide solution with a concentration of 23wt% with deionized water, add sodium metasulfite and sodium acrylate with a total mass of 0.2% of the reactants, and the mass ratio of sodium acrylate to acrylamide monomer is 1:2.5, and use 30wt% NaOH solution was poured into the reactor after adjusting the pH to 8. The reactor was placed in a constant temperature water bath to maintain a constant temperature (initial temperature 9° C.) and nitrogen was blown for 30 minutes. Add 0.4% of the total mass of the reactant modified silicone (3-aminopropyltriethoxysilane KH550), and then add the corresponding initiator system agent: the amount of chain transfer agent added is 0.02% of the total mass of the reactant, The amount of redox agent added is 20% of the total mass of reactants (potassium persulfate is the oxidizing agent, sodium bisulfite is the reducing agent, and the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com