Full-machine-made sand masonry mortar taking limestone as aggregate and preparation method thereof

A limestone machine-made sand and masonry mortar technology, which is applied in the field of building materials, can solve the problems of unsuitable long-distance transportation, air and water and soil pollution, uneven machine-made sand particles, etc., and achieve improved capacity, increased binding force, and improved heat storage The effect of capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

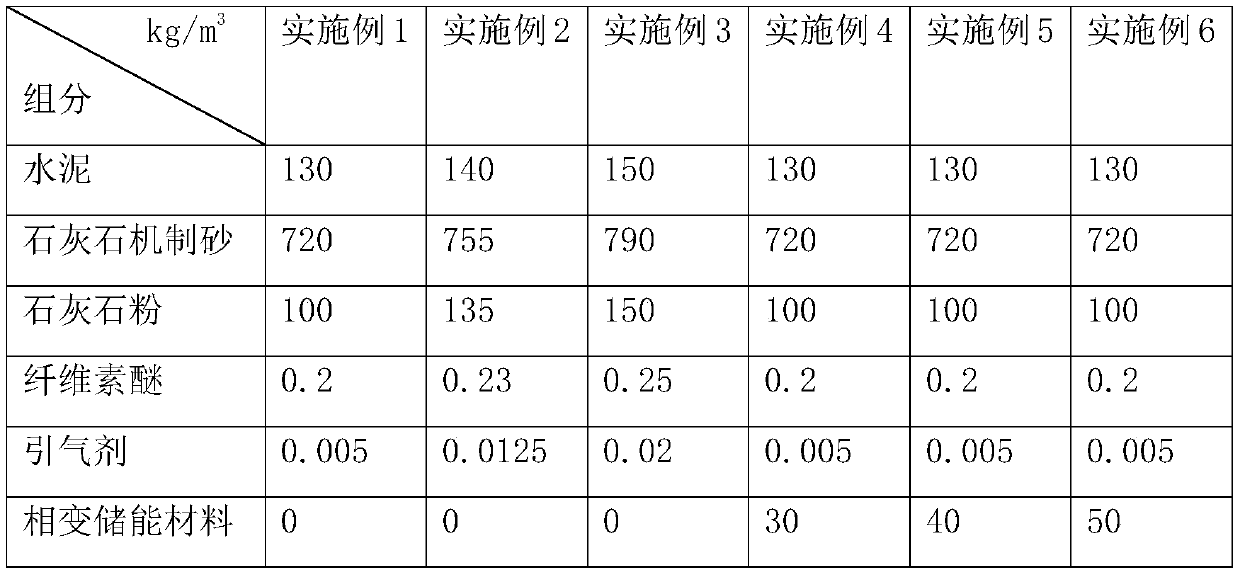

Examples

preparation example 1-3

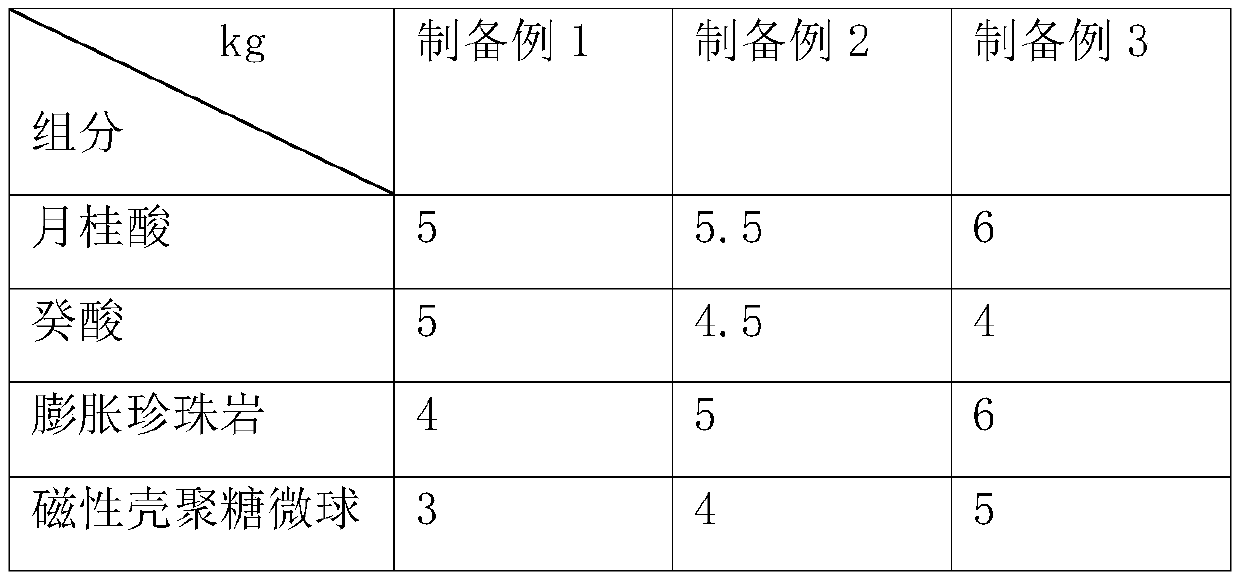

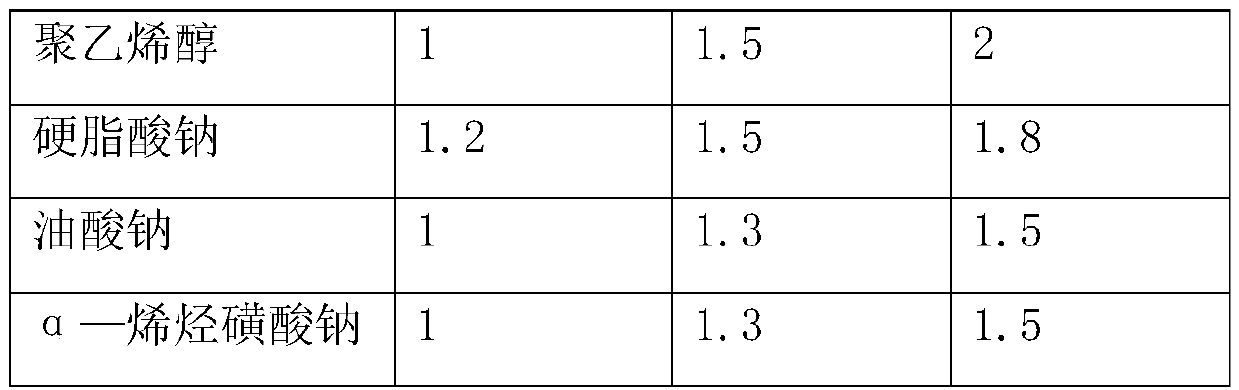

[0034] In Preparation Example 1-3, the magnetic chitosan microspheres were selected from Zhengzhou Yingnuo Biotechnology Co., Ltd., the sodium α-olefin sulfonate was selected from Nantong Runfeng Petrochemical Co., Ltd., and the model was AOS; the polyvinyl alcohol was selected from Inner Mongolia Kaidu New Material Technology Co., Ltd., model 1788.

preparation example 1

[0035] Preparation Example 1: According to the ratio of raw materials in Table 1, heat 5kg of lauric acid, 5kg of capric acid, 4kg of expanded perlite and 3kg of magnetic chitosan microspheres in a constant temperature water bath to 50°C, stir while heating, and keep the temperature constant for 30min , add 1kg polyvinyl alcohol and 1.2kg sodium stearate, raise the temperature to 75-85°C, continue stirring at constant temperature for 20min, vacuum adsorption for 15min under the condition of 0.05MPa, add 1kg sodium oleate and 1kg alpha-olefin sulfonate sodium, stir well Finally, under the condition of 0.08MPa, vacuum adsorption for 15 minutes, the phase change energy storage material was prepared. The particle size of expanded perlite was 50 mesh, and the mesh number of polyvinyl alcohol was 80 mesh. The chemical properties of expanded perlite are shown in Table 2 .

[0036] Raw material ratio of phase change energy storage material in preparation example 1-3 in table 1

[003...

preparation example 2

[0041] Preparation example 2: according to the ratio of raw materials in table 1, 5.5kg lauric acid, 4.5kg capric acid, 5kg expanded perlite and 4kg magnetic chitosan microspheres are heated to 60 ℃ in a constant temperature water bath, and stirred while heating, Keep the temperature for 25 minutes, add 1.5kg of polyvinyl alcohol and 1.5kg of sodium stearate, raise the temperature to 80°C, continue stirring at a constant temperature for 25 minutes, vacuum adsorption for 13 minutes under the condition of 0.08MPa, add 1.3kg of sodium oleate and 1.3kg of sodium α-olefin sulfonate , after stirring evenly, vacuum adsorption under the condition of 0.1MPa for 13min, the phase change energy storage material was prepared, the particle size of expanded perlite was 60 mesh, and the mesh number of polyvinyl alcohol was 100 mesh. The chemical properties of expanded perlite are shown in the table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com