A kind of production equipment and production process of biochar-based compound fertilizer

A production equipment and technology of biochar, which is applied in the direction of carbon preparation/purification, fertilization device, fertilizer mixture, etc., can solve the problem of limiting the slow-release effect of biochar and fertilizer, and it is difficult to ensure that inorganic fertilizers, organic fertilizers and biochar are close and stable Combination, difficult to mix evenly, etc., to achieve good modification and peeling effect, improve modification and peeling effect, and increase specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

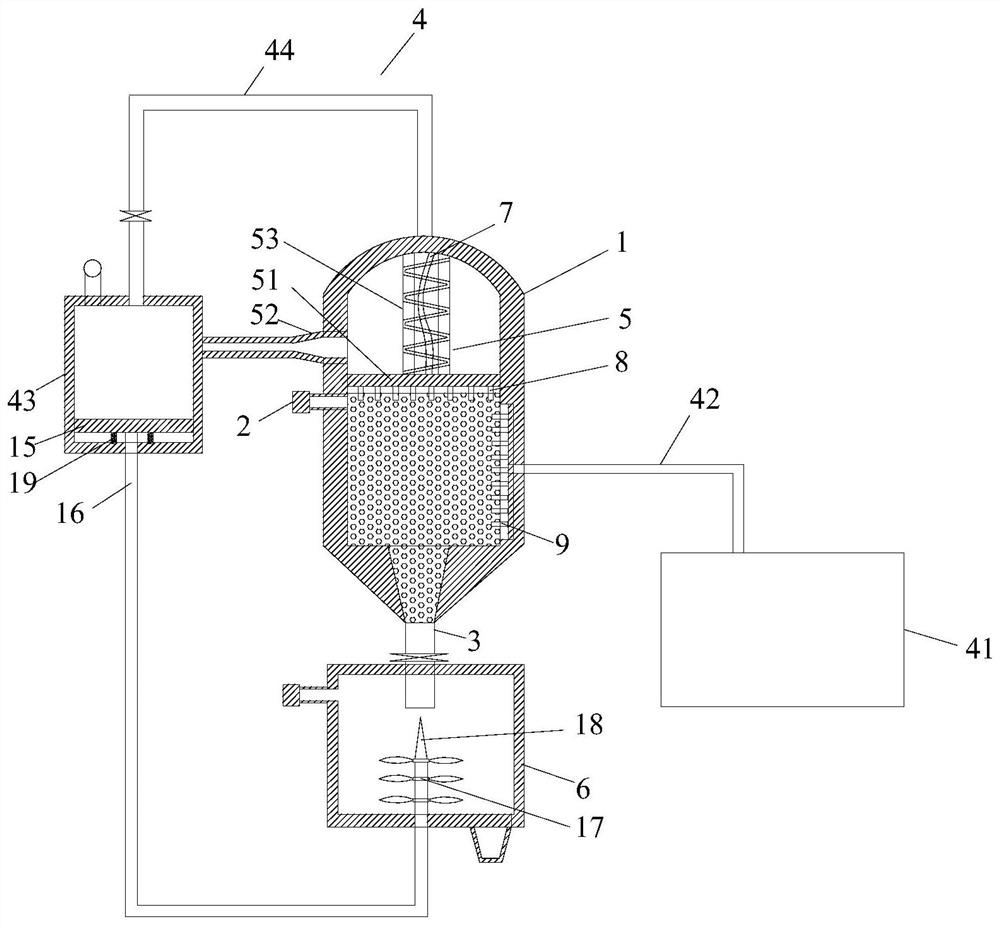

[0037] A production equipment for biochar-based compound fertilizer provided by the present invention includes: a biochar modification chamber 1 configured to prepare modified biochar; a feed port 2 is provided on the side wall of the biochar modification chamber 1 , the bottom is provided with a discharge port 3, the feed port 2 is provided with a blocking member, and the discharge port 3 is provided with a control valve;

[0038] The water vapor circulation mechanism 4 includes a water vapor supply device 41, and a first air inlet pipe 42 for delivering the hot gas to the biochar reforming chamber 1 in a horizontal direction, and the biochar reforming chamber 1 is also connected with a a buffer device 43 for reheating the exhaust gas from the biochar reforming chamber 1, the buffer device 43 feeds the reheated gas into the biochar reforming chamber 1 in a vertical direction through the second air inlet pipe 44;

[0039] The pressure relief mechanism 5 is arranged in the bioc...

Embodiment 2

[0044] On the basis of Embodiment 1, the pressure relief mechanism 5 includes

[0045]11. Pressure relief mechanism 5 includes

[0046] The first piston plate 51 is sealingly connected to the inner wall of the biochar modification chamber 1, and can slide up and down along the inner wall of the biochar modification chamber 1; the second air inlet pipe 44 is connected to the first piston plate 51 through the connecting hose 7 , the first piston plate 51 is provided with a first gas exporting device 8 for transmitting gas to the biochar reforming chamber 1;

[0047] The exhaust port 52 is arranged on the side wall between the first piston plate 51 and the top of the biochar reforming chamber 1;

[0048] The elastic connecting piece 53 is used to connect the first piston plate 51 with the top of the biochar reforming chamber 1 .

[0049] The working principle is as follows: when water vapor is supplied into the biochar modification chamber 1 through the first air inlet pipe 42,...

Embodiment 3

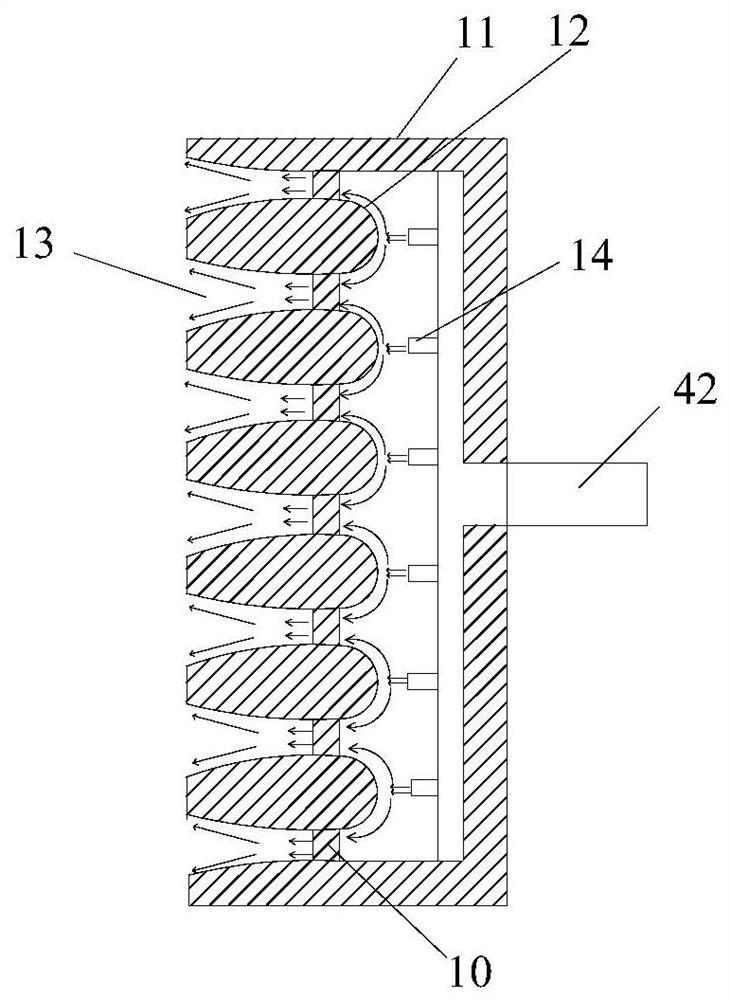

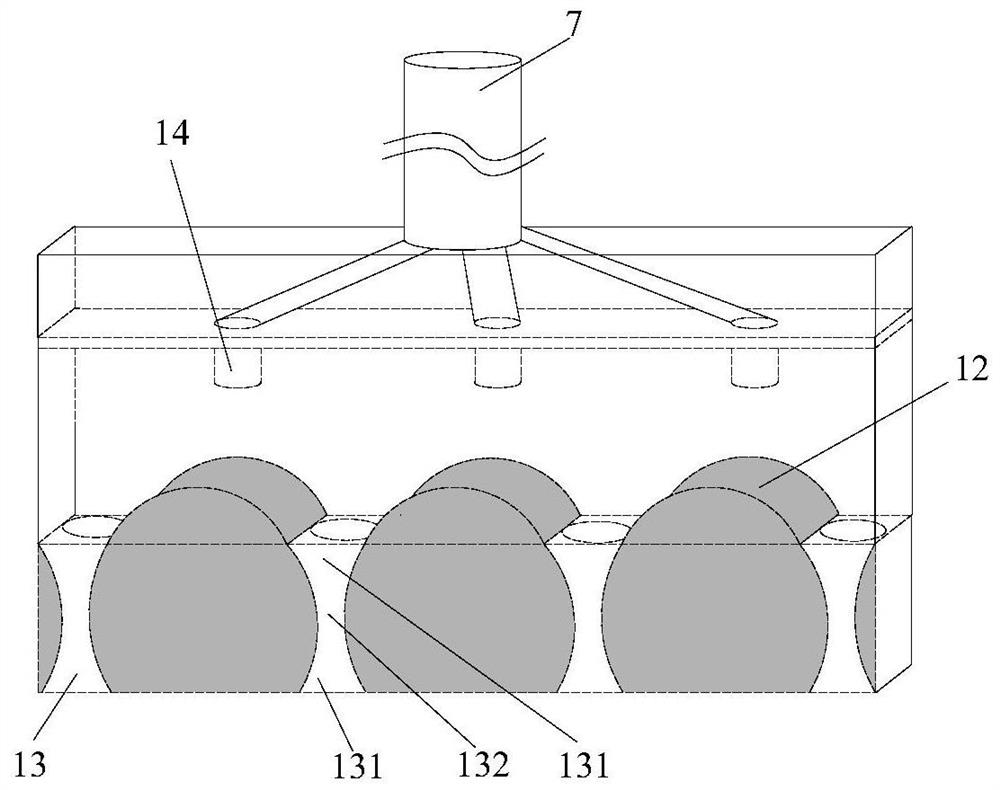

[0051] On the basis of the above embodiment, in order to make the water vapor entering the biochar reforming chamber 1 have a higher speed and improve the peeling efficiency, the first air inlet pipe 42 is connected with a second gas outlet device 9, the first Both the gas lead-out device 8 and the second gas lead-out device 9 include a split gas guide member 10 and an outer casing 11 , and a plurality of arc-shaped protrusions 12 are evenly distributed on the outer surface of the split-flow gas guide member 10 . A gas acceleration channel 13 is provided at the peak and valley of the starting point 12. The gas acceleration channel 13 includes two flared ends 131 and a narrow throat 132 located between the two flared ends 131. The outer shell 11 There are air nozzles 14 thereon, the air nozzles 14 are in one-to-one correspondence with the tops of the arcuate protrusions 12 , and the air nozzles 14 communicate with the connecting hose 7 or the first air inlet pipe 42 .

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com