Board chamfering device for wood furniture production

A technology for wooden furniture and chamfering device, which is applied to grinding/polishing safety devices, manufacturing tools, grinding skateboards, etc., can solve the problems affecting the processing efficiency of wooden furniture, low processing efficiency, etc. Simple and convenient loading and unloading, protection and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

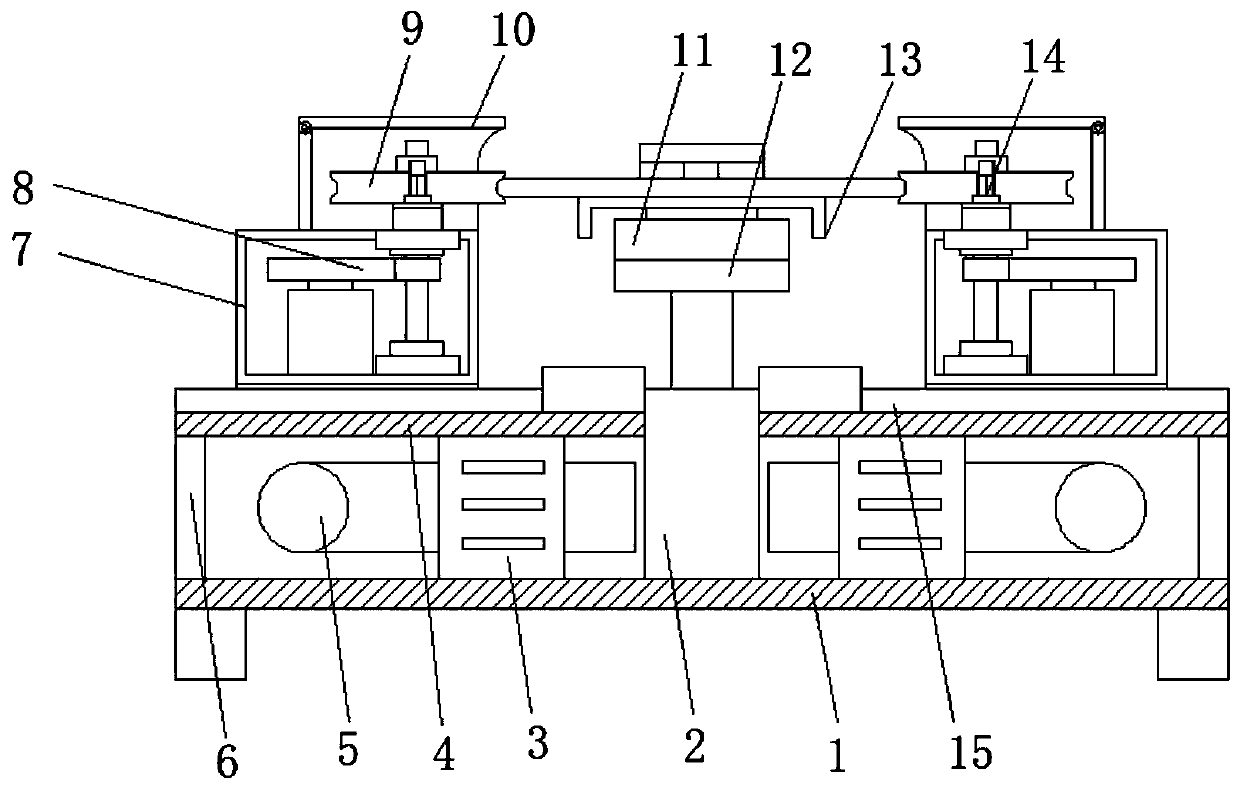

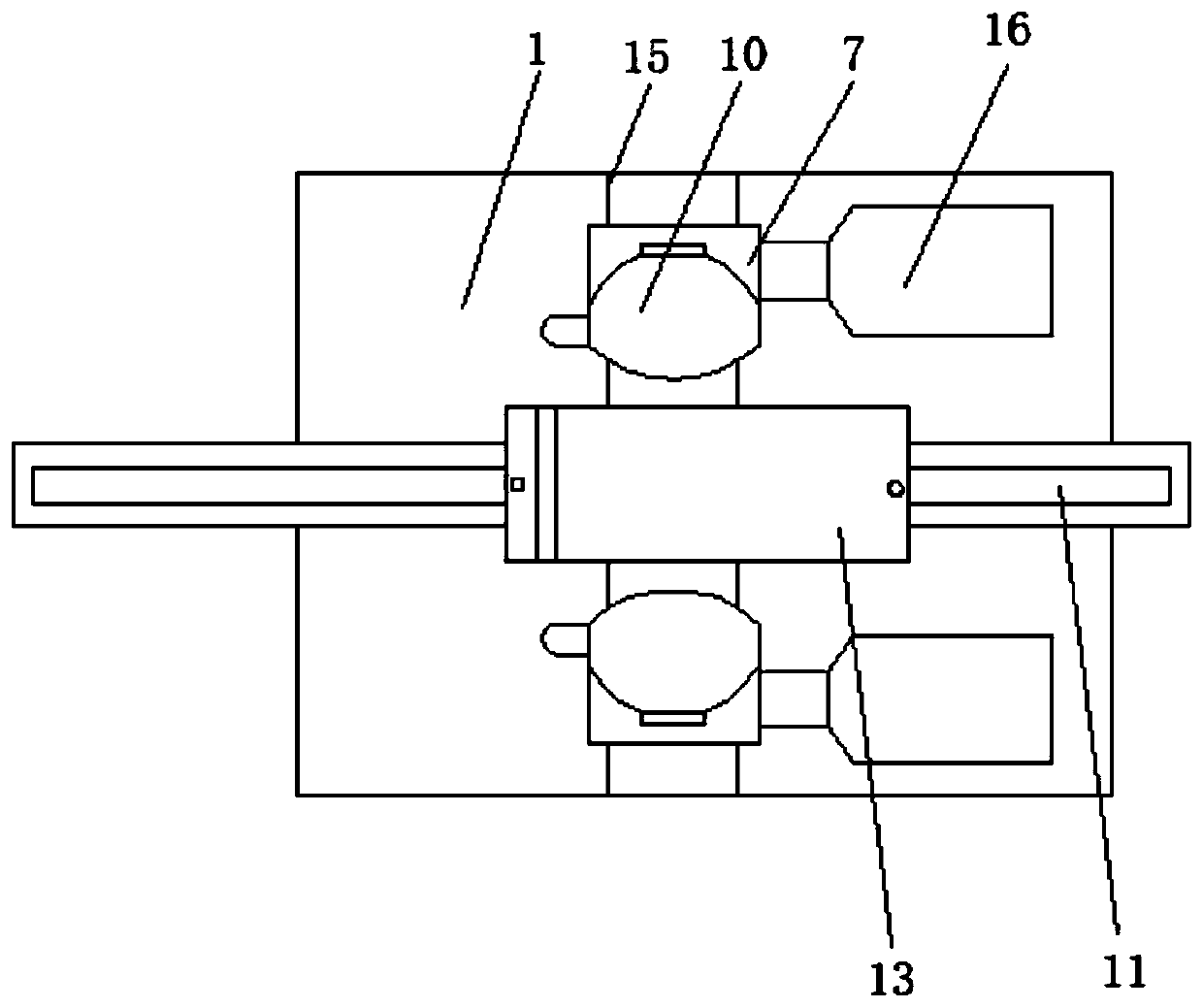

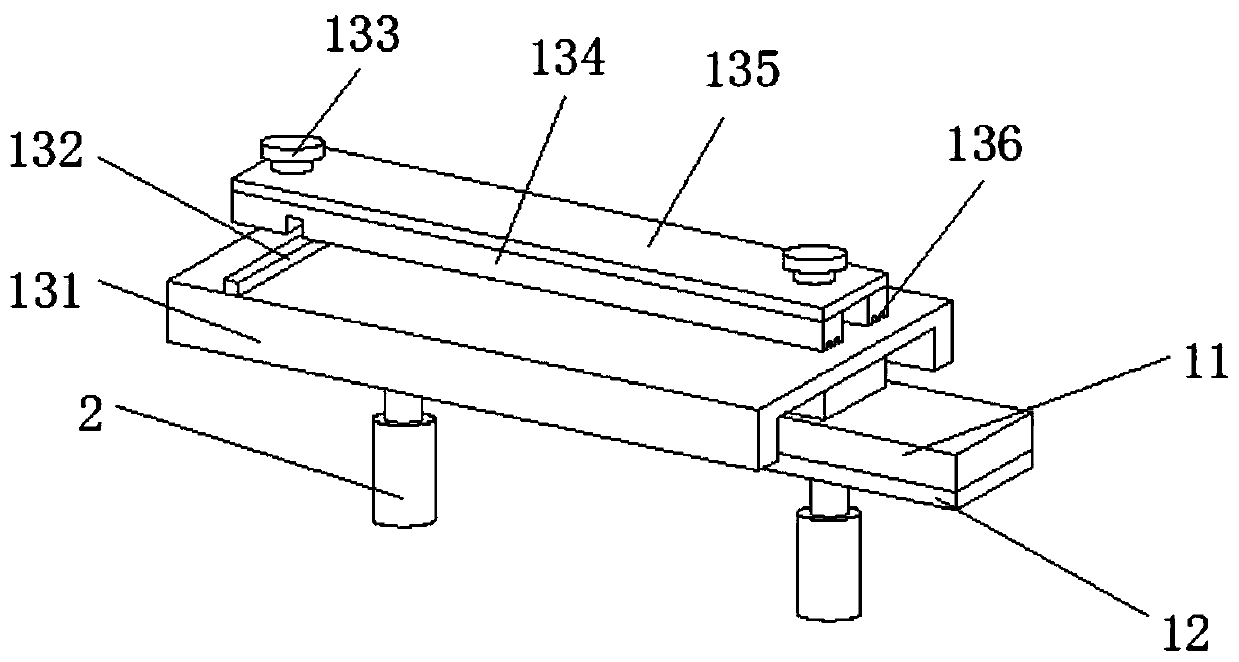

[0026] refer to Figure 1-3 , a board chamfering device for wooden furniture production, comprising a base 1, a plurality of electric push rods 2 are fixedly installed in the middle of the top of the base 1, and support plates 6 are fixedly installed on both sides of the top of the base 1, and the support plates 6 A platen 4 is fixedly installed between the top and the electric push rod 2, and an electric sliding table 15 is fixedly installed on the top of the table plate 4, and a housing 7 is fixedly installed on the tops of the two electric sliding tables 15, and the housing 7 The top is equipped with a rotating rod 14 through a bearing, and the inside of the housing 7 is fixedly installed with a drive mechanism 8 connected to the rotating rod 14. A lifting table 12 is fixedly installed between them, and an auxiliary electric sliding table 11 is fixedly installed on the top of the lifting table 12, a feeding mechanism 13 is fixedly installed on the top of the auxiliary elect...

Embodiment 2

[0034] refer to Figure 1-4 , a board chamfering device for wooden furniture production. Compared with Embodiment 1 in this embodiment, the isolation cover 10 includes a side plate 102 and a cover body 103 hinged on the top of the side plate 102, and the side surface of the cover body 103 is provided with a The short pipe 101 connected to the dust removal mechanism; the top end of the cover body 103 is in an arc-shaped structure, and both sides of the bottom of the cover body 103 are fixed with magnetic steel plates 104 .

[0035] In this embodiment: the isolation cover 10 is divided into a fixed side plate 102 and a movable cover body 103. When the chamfering grinding wheel 9 needs to be replaced, it is only necessary to lift the cover body 103. After the cover body 103 is installed, it relies on the magnetic steel plate 104 Mutual magnetic attraction with the housing 7, easy and convenient loading and unloading, and convenient operation. At the same time, the top of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com