Method for machining roller by adopting nine-axis machine tool and roller produced by using method

A lathe processing and machine tool technology, applied in the field of mask processing equipment, can solve the problems of low manual pass rate, high manufacturing cost, and time-consuming, etc., and achieve the effect of improving product pass rate, reducing production cycle, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

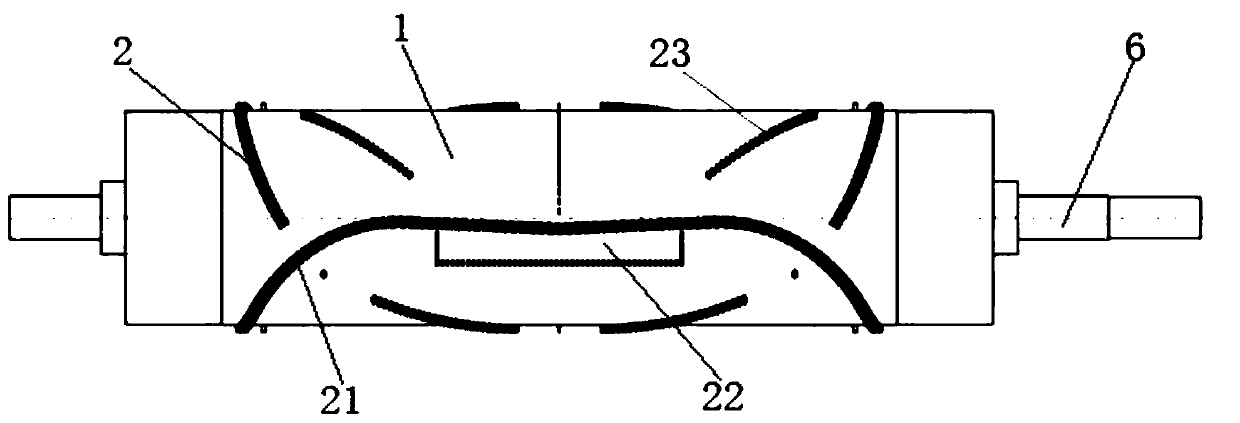

[0038] Such as figure 1 and Figure 4 As shown, the roller produced by the method of processing the roller with a nine-axis machine tool is a mask fabric press-welded gear roller, including the No. 1 shaft body 1, and the No. 1 shaft body 1 is provided with a The No. 1 welded tooth point 2 with a symmetrical cross-section distribution; the two ends of the No. 1 shaft body 1 are provided with chucks 6 .

[0039] The No. 1 welding tooth point 2 includes the No. 1 tooth point 21 of welding the outline of the fish-shaped mask, the No. 2 tooth point 22 of the welding nose clip part, and the No. 3 tooth point 23 of the welding fabric edge; the No. 3 tooth point 23 is along the The central cross-section of the No. 1 shaft body 1 is distributed symmetrically.

Embodiment 2

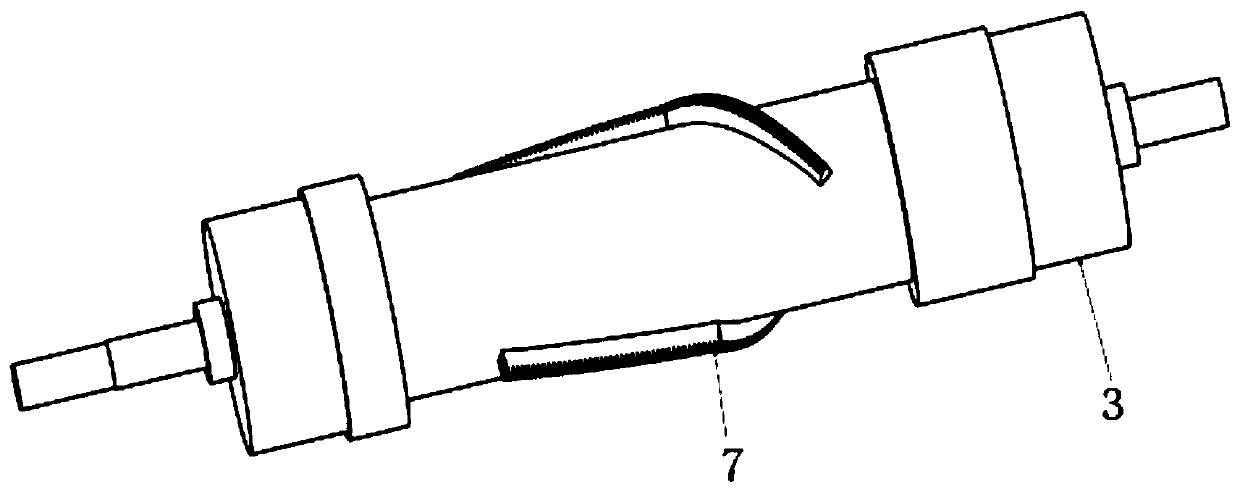

[0041] Such as figure 2 and Figure 5 As shown, the roll produced by the method of processing the roll with a nine-axis machine tool is a mask press-welded gear roll, including the second shaft body 3, and the second shaft body 3 is provided with a shaft formed around the axis of the second shaft body 3. Two sections of No. 2 welding tooth points 7 in spiral distribution; after the No. 2 shaft body 3 rotates around the axis for one week, the weld marks on the mask cloth are distributed in a broken line shape; Welding: A spherical milling cutter with a diameter of 1 mm cleans the gap between two adjacent tooth points of No. 1 welding tooth point 2 and No. 2 welding tooth point 7, and corrects the inclination angle of the tooth points at the same time.

Embodiment 3

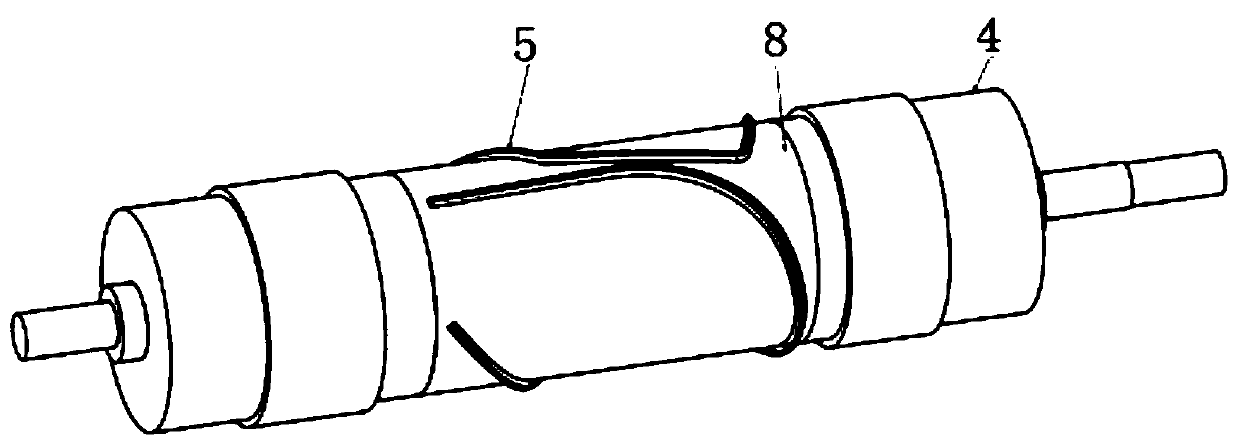

[0043] Such as image 3 and Figure 6 As shown, the roller produced by the method of processing the roller with a nine-axis machine tool is a mask fabric cutting roller, including a No. Finally, the knife edge 5 of the fish-shaped incision appears in the mask cloth; the fish-shaped incision cut out by the knife edge 5 on the mask cloth is an unclosed incision; because the knife edge 5 is not composed of tooth points but directly mills out the entire section through dynamic roughing For the cutting edge, after using the ball milling cutters with diameters of 6mm, 4mm and 3mm to correct only the position and shape of the cutting edge 5, there is no need to use a ball milling cutter with a diameter of 1mm for processing.

[0044] The rubber ring 8 that increases the friction force between the No. 3 shaft body 4 and the mask cloth is set on the No. 3 shaft body 4; the rubber ring 8 increases the friction force between the mouth mask and the No. 3 shaft body 4 to prevent the mask ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com