Anti-oxidation solder alloy for tin-plated copper strip coating and preparation method of anti-oxidation solder alloy

A technology of tinned copper strip and solder alloy, applied in welding equipment, metal processing equipment, welding/cutting medium/material, etc., can solve the problem of affecting the welding effect of tinned copper strip, uneven surface thickness of coating, damage to product life, etc. problems, to achieve the effect of simple formula and process, uniform distribution of alloy on the surface of the coating, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

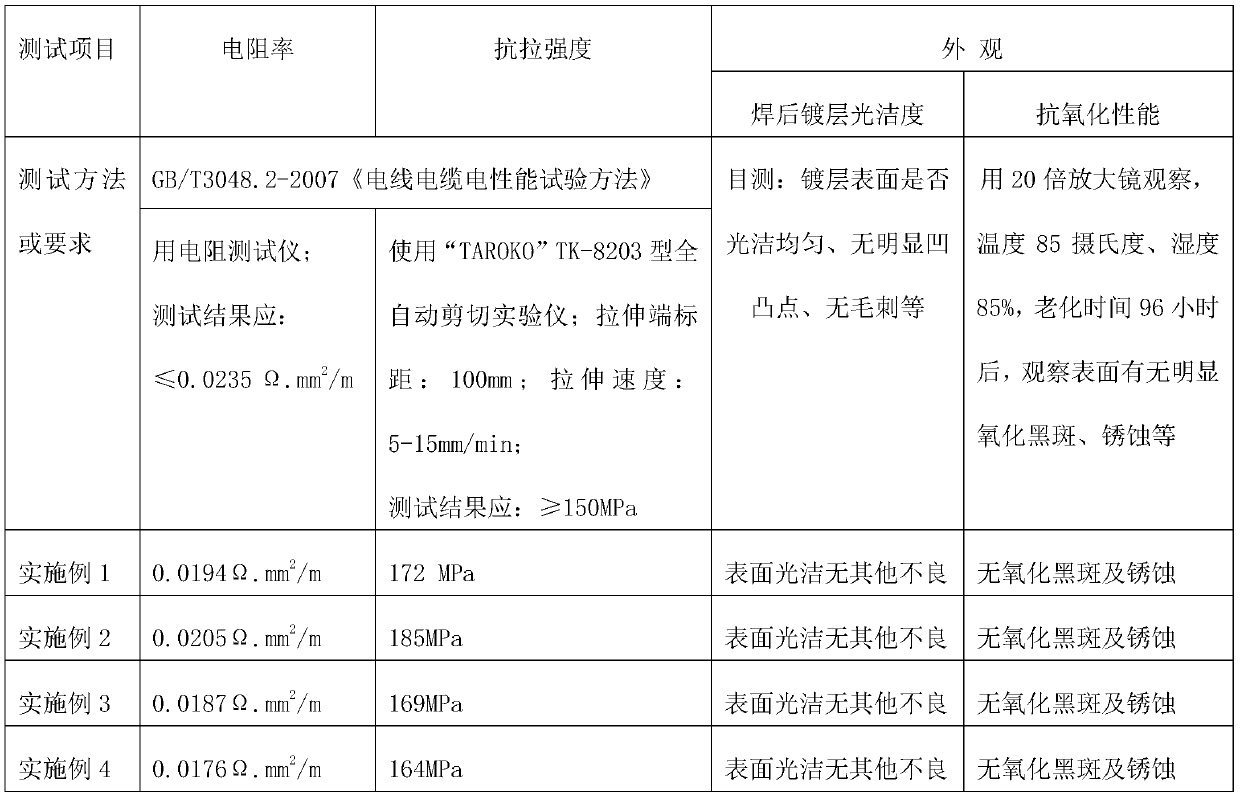

Examples

Embodiment 1

[0023] A tin-plated copper strip coating anti-oxidation solder alloy is prepared according to the following steps:

[0024] Step 1, prepare the basic material of component (1): tin (Sn, purity 99.99%) 92.4Kg, heat to 360°C to form high-temperature liquid tin;

[0025] Step 2, prepare component (2) reinforcing material: bismuth (Bi) 5.5Kg, copper (Cu) 0.9Kg, antimony (Sb) 0.8Kg, and add to the high-temperature liquid tin in step 1 in turn, and keep stirring until completely melted , to obtain the master alloy;

[0026] Step 3: Slowly lower the temperature of the master alloy in step 2 to 220°C, and at the same time remove the oxide slag, oxide ash and other sundries generated on the surface of the master alloy, and then add the antioxidant material of component (3): Gallium (Ga) 0.2Kg Add 0.2Kg of germanium (Ge) into the master alloy, and keep stirring until it is completely melted to obtain tin-plated copper strip coating anti-oxidation solder alloy.

Embodiment 2

[0028] A tin-plated copper strip coating anti-oxidation solder alloy is prepared according to the following steps:

[0029] Step 1, prepare component (1) base material: tin (Sn, purity 99.99%) 93.3Kg, heat to 360 ℃ to form high-temperature liquid tin;

[0030] Step 2, prepare component (2) reinforcing material: bismuth (Bi) 5.0Kg, copper (Cu) 0.5Kg, antimony (Sb) 0.9Kg, and add to the high-temperature liquid tin in step 1 in turn, and keep stirring until completely melted , to obtain the master alloy;

[0031] Step 3: Slowly lower the temperature of the master alloy in step 2 to 220°C, and at the same time remove the oxide slag, oxide ash and other sundries generated on the surface of the master alloy, then add component (3) anti-oxidation material: gallium (Ga) 0.1Kg, Add germanium (Ge) 0.2Kg into the master alloy, and keep stirring until it is completely melted to obtain tin-plated copper strip coating anti-oxidation solder alloy.

Embodiment 3

[0033] A tin-plated copper strip coating anti-oxidation solder alloy is prepared according to the following steps:

[0034] Step 1, prepare component (1) base material: tin (Sn, purity 99.99%) 93.9Kg, heat to 360°C to form high-temperature liquid tin;

[0035] Step 2, prepare component (2) reinforcing material: bismuth (Bi) 4.0Kg, copper (Cu) 0.7Kg, antimony (Sb) 0.9Kg, and add to the high-temperature liquid tin in step 1 in turn, and keep stirring until completely melted , to obtain the master alloy;

[0036] Step 3: Slowly lower the temperature of the master alloy in step 2 to 220°C, and at the same time remove the oxide slag, oxide ash and other sundries generated on the surface of the master alloy, then add component (3) anti-oxidation material: Gallium (Ga) 0.2Kg, Add germanium (Ge) 0.3Kg into the master alloy, and keep stirring until it is completely melted to obtain tin-plated copper strip coating anti-oxidation solder alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com