Preparation method of graded hollow silica confined cuprous oxide visible light catalyst

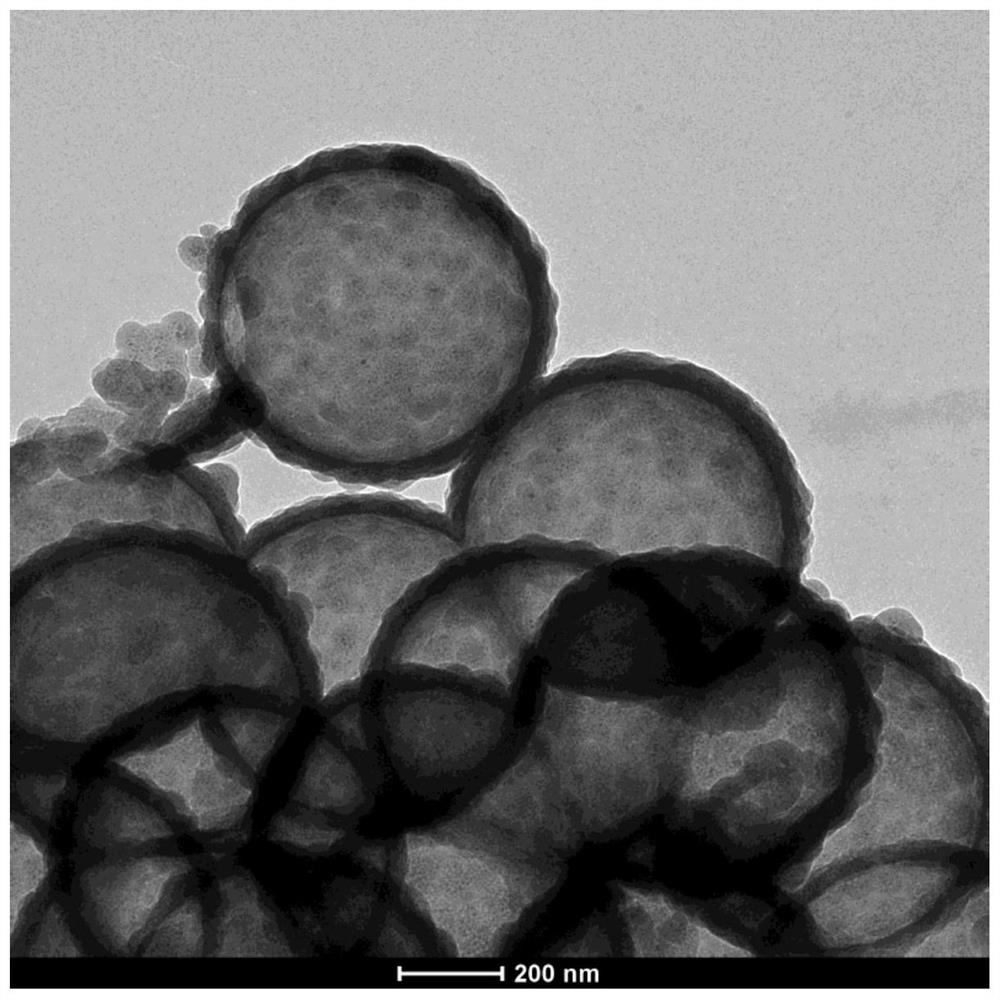

A technology of silica and cuprous oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, preparation of organic compounds, etc. It can solve the problem of inability to realize efficient and selective hydrogenation of nitroaromatics, etc. problem, to achieve the effect of increasing photon yield, uniform shell thickness, and improving photon quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

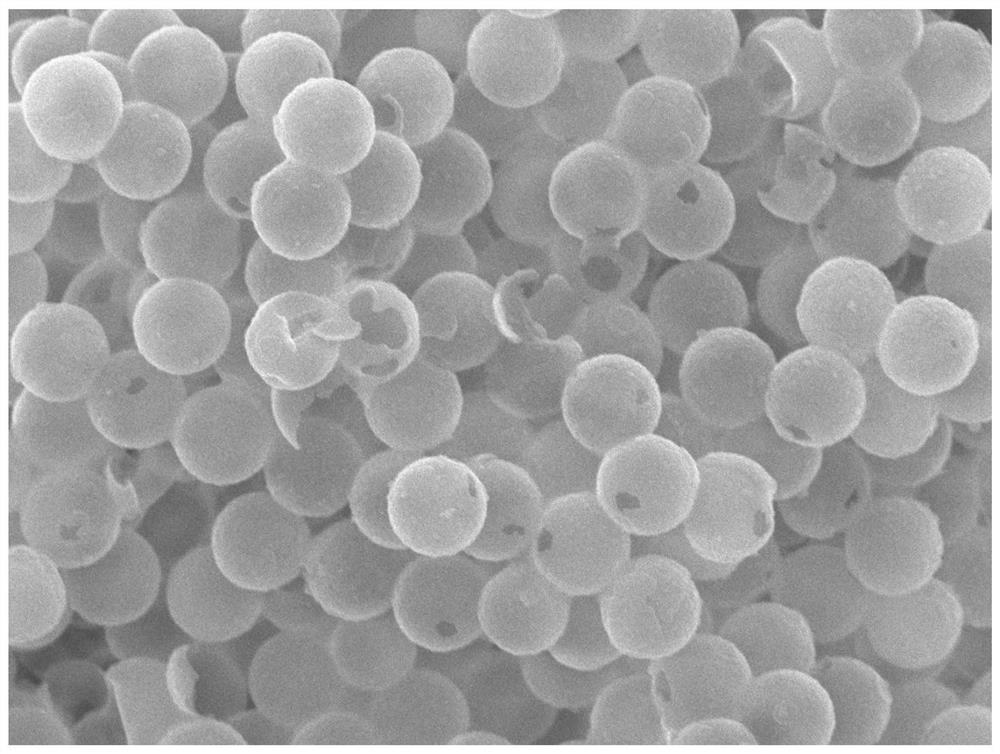

[0044] (1) Preparation of cationic template CPS: set up the experimental device and introduce nitrogen into the system, add 72 mL of water to the four-necked flask, heat the water bath to 70°C, and sequentially add 0.16 g of initiator and 7.5 g of styrene to start the stirring reaction 1.5h, then add the modifier methacryloyloxyethyltrimethylammonium chloride aqueous solution, the first three injections are one injection every half an hour (10 μl per injection), and then two injections are injected, one injection every hour, every Needle is (50 μl). The remaining solution is then injected every 3 minutes, each injection (10 μl), until all remaining methacryloyloxyethyltrimethylammonium chloride (DMC) has been injected, and the injection is 1.1 g. After the injection of the mixed solution obtained by methacryloyloxyethyltrimethylammonium chloride and 1.2 g of deionized water was completed, the polymerization was extended for another 12 hours to make it fully polymerized. After...

Embodiment 2

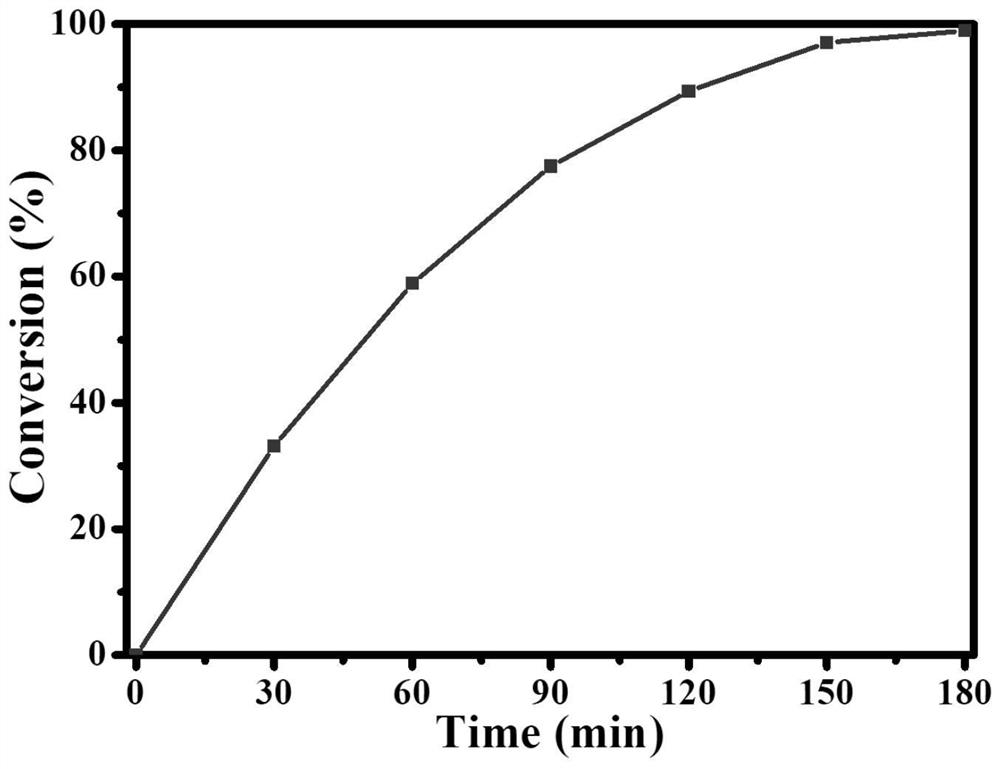

[0050] SiO 2 -Cu 2 O@SiO 2 The photocatalyst reduces o-chloronitrobenzene;

[0051] Pour 20 mL (1 mg / mL) of the prepared o-chloronitrobenzene deionized aqueous solution into the reactor, add 25 mg of catalyst and 27 mg of formic acid, and study its photocatalytic behavior under the action of visible light. Samples were taken every 30 minutes and analyzed by high performance liquid chromatography to obtain the reduction changes of o-chloronitrobenzene at different reduction times, and finally the conversion rate and selectivity of o-chloronitrobenzene were calculated according to the obtained data. The results show that the photocatalyst of the present invention can realize the complete conversion of o-chloronitrobenzene under visible light.

Embodiment 3

[0053] SiO 2 -Cu 2 O@SiO 2 The photocatalyst reduces o-chloronitrobenzene;

[0054] 40 mL (1 mg / mL) of the prepared o-chloronitrobenzene deionized aqueous solution was poured into the reactor, 25 mg of catalyst and 54 mg of formic acid were added, and its photocatalytic behavior was studied under the action of visible light. Samples were taken every 30 minutes and analyzed by high performance liquid chromatography to obtain the reduction changes of o-chloronitrobenzene at different reduction times, and finally the conversion rate and selectivity of o-chloronitrobenzene were calculated according to the obtained data. The results show that the photocatalyst of the present invention can realize the complete conversion of o-chloronitrobenzene under visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com