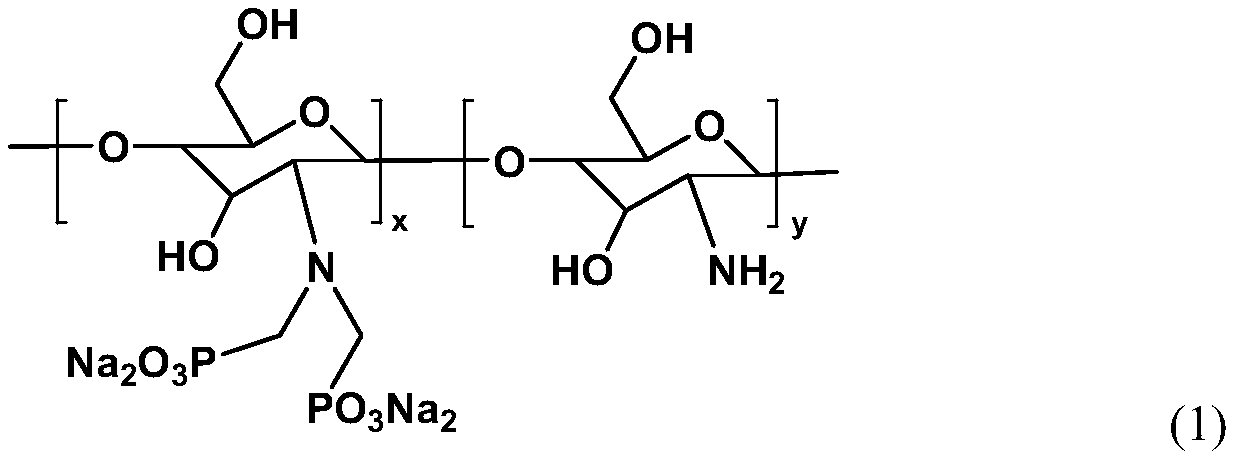

Chitosan oligosaccharide intermediate, preparation method thereof and application of chitosan oligosaccharide intermediate in preparation of phosphonate water reducing agent

A technology of chitosan oligosaccharide and intermediate, which is applied in the field of concrete admixtures, can solve the problems of water-soluble and water-reducing performance decline of water-reducing agent, application limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

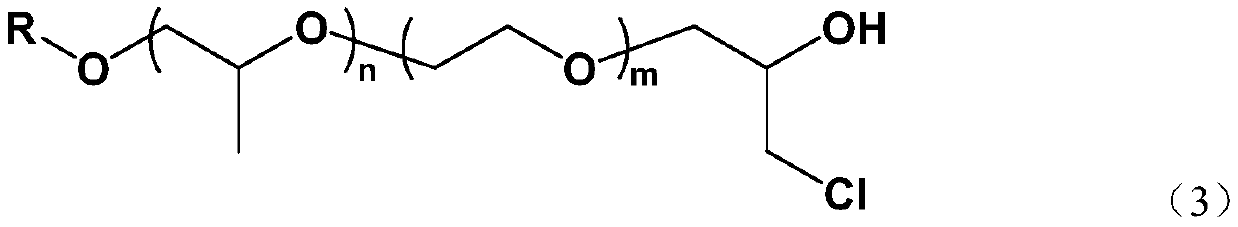

[0049] Weigh 100.0 parts of ethanol as an initiator, add 0.02 part of catalyst DMC, seal the reaction vessel, and replace with nitrogen for 3 times. Raise the temperature to 100°C, and feed 20.0 parts of propylene oxide. After the induced reaction occurs (the temperature in the kettle rises and the pressure drops), continue to feed 230.0 parts of propylene oxide, and control the reaction temperature between 120 and 140°C. ≤0.4MPa, heat preservation reaction for 10 minutes after feeding, then feed 1820.0 parts of ethylene oxide, heat insulation reaction for 10 minutes after feeding, finally feed 200.0 parts of epichlorohydrin, heat insulation reaction for 30 minutes after feeding, and cool down to After discharge at 80°C, 2693.0 parts of colorless and transparent polyether was obtained, denoted as P-1. After testing, the number average molecular weight of the polyether was Mn=1035, and the molecular weight distribution PDI=1.08.

[0050] Similarly, the following chlorinated pol...

preparation example 2

[0059] Weigh 100.0 parts of chitosan oligosaccharide with number average molecular weight Mn=483, add 40.0 parts of solvent water, 5.0 parts of catalyst solid heteropolyacid, and 67.9 parts of phosphorous acid, and start stirring. Raise the temperature to 80°C, stir until the materials are fully mixed, add 24.8 parts of paraformaldehyde, seal the reaction kettle, raise the temperature to 100°C, and keep it warm for 15 hours. After the reaction was completed, the catalyst solid heteropolyacid was separated by vacuum filtration, and 103.5 parts of 32% NaOH aqueous solution was added to the filtered liquid to obtain the chitosan oligosaccharide intermediate.

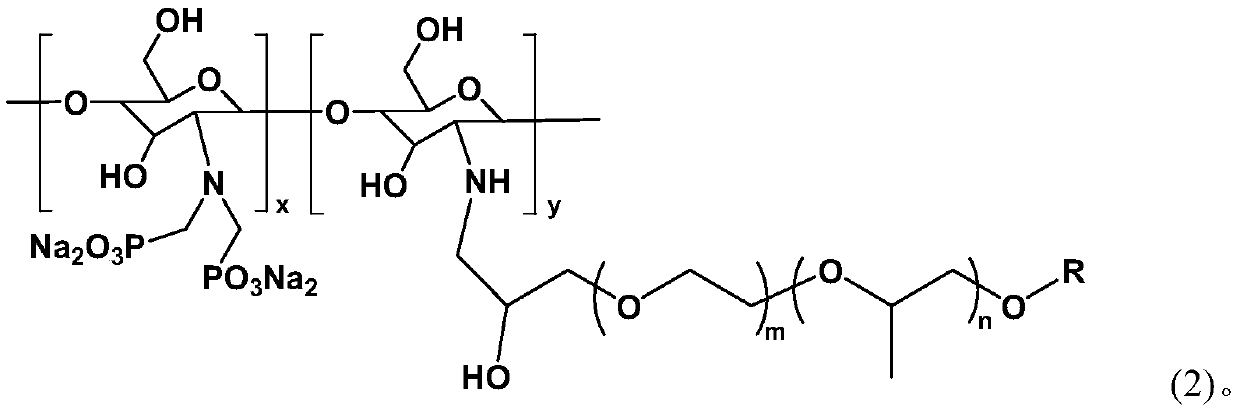

[0060] Add 1029.6 parts of P-5 polyether to the chitosan oligosaccharide intermediate, raise the temperature to 150°C, and keep warm for 15 hours to obtain the finished product of phosphonic acid-based water reducer, which is denoted as PCA-1. After testing, the weight average molecular weight of the water reducer Mw= 5672,...

preparation example 3

[0062] Weigh 100.0 parts of chitosan oligosaccharide with number average molecular weight Mn=1610, add 50.0 parts of solvent water, 8.0 parts of catalyst solid superacid, and 50.9 parts of phosphorous acid, and start stirring. Raise the temperature to 80°C, stir until the materials are fully mixed, add 60.4 parts of 37% formaldehyde, seal the reaction kettle, raise the temperature to 120°C, and keep it warm for 10 hours. After the reaction was completed, the catalyst solid superacid was separated by vacuum filtration, and 77.6 parts of 32% NaOH aqueous solution was added to the filtered liquid to obtain a wine-red oligochitosan intermediate solution.

[0063] Add 1246.3 parts of P-4 polyether to the chitosan oligosaccharide intermediate, raise the temperature to 130°C, and keep it warm for 10 hours to obtain a tan phosphonic acid-based water reducer, which is denoted as PCA-2. After testing, the weight average of the water reducer is Molecular weight Mw=21014, molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com