Secondary machining process for oil hole of hydraulic cylinder of horizontal jack

A secondary processing and hydraulic cylinder technology, which is applied in the field of hydraulic cylinders of horizontal jacks, can solve the problems of low verticality of knocking, hindering the normal movement of the pushing piston, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] An embodiment of the secondary processing technology of the oil hole of a horizontal jack hydraulic cylinder according to the present invention, the specific steps include:

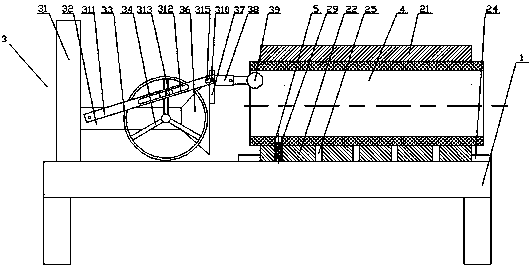

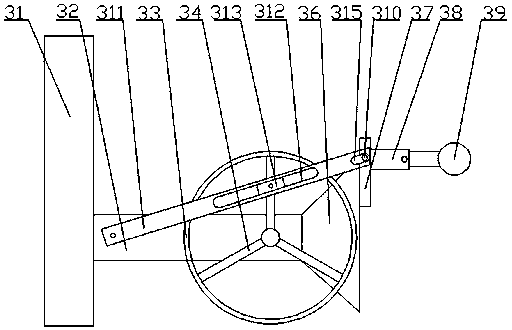

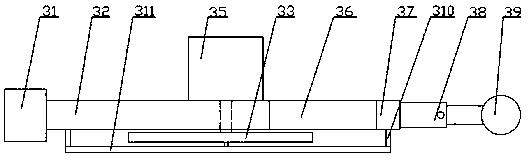

[0040] S1, positioning the oil hole knocking device, such as figure 1 As shown, the oil hole knocking device includes an operating platform 1 and a clamping table 2 placed on the operating platform 1 for clamping the hydraulic cylinder 4. The operating platform 1 has a knocking assembly 3, and the knocking assembly 3 is placed on the hydraulic cylinder. 4 side;

[0041] The clamping table 2 includes a lower clamping body 21 and an upper clamping body 22 hinged to each other. There is a cavity 23 in which the hydraulic cylinder 4 is embedded horizontally between the upper clamping body 22 and the lower clamping body 21. The operating platform 1 has The slide rail 24 that accommodates the horizontal and linear movement of the clamping table 2, the lower clamping body 21 is fixed on the operating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com