Installation equipment for assembling excavator big arm center box group

A technology of central box and installation equipment, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of difficult to guarantee the processing quality, easy deflection of the workpiece, unable to fix firmly and ensure the accuracy of positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

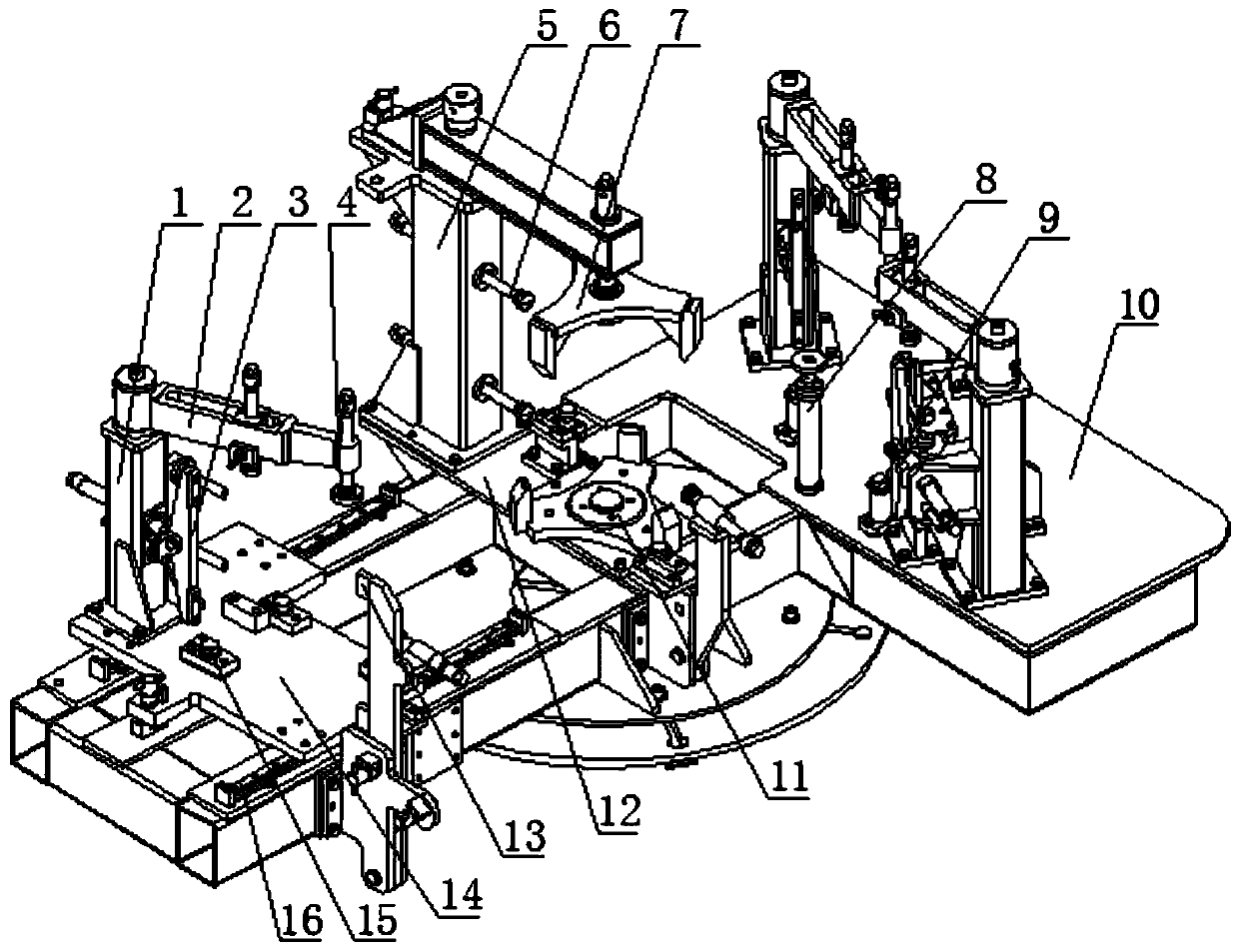

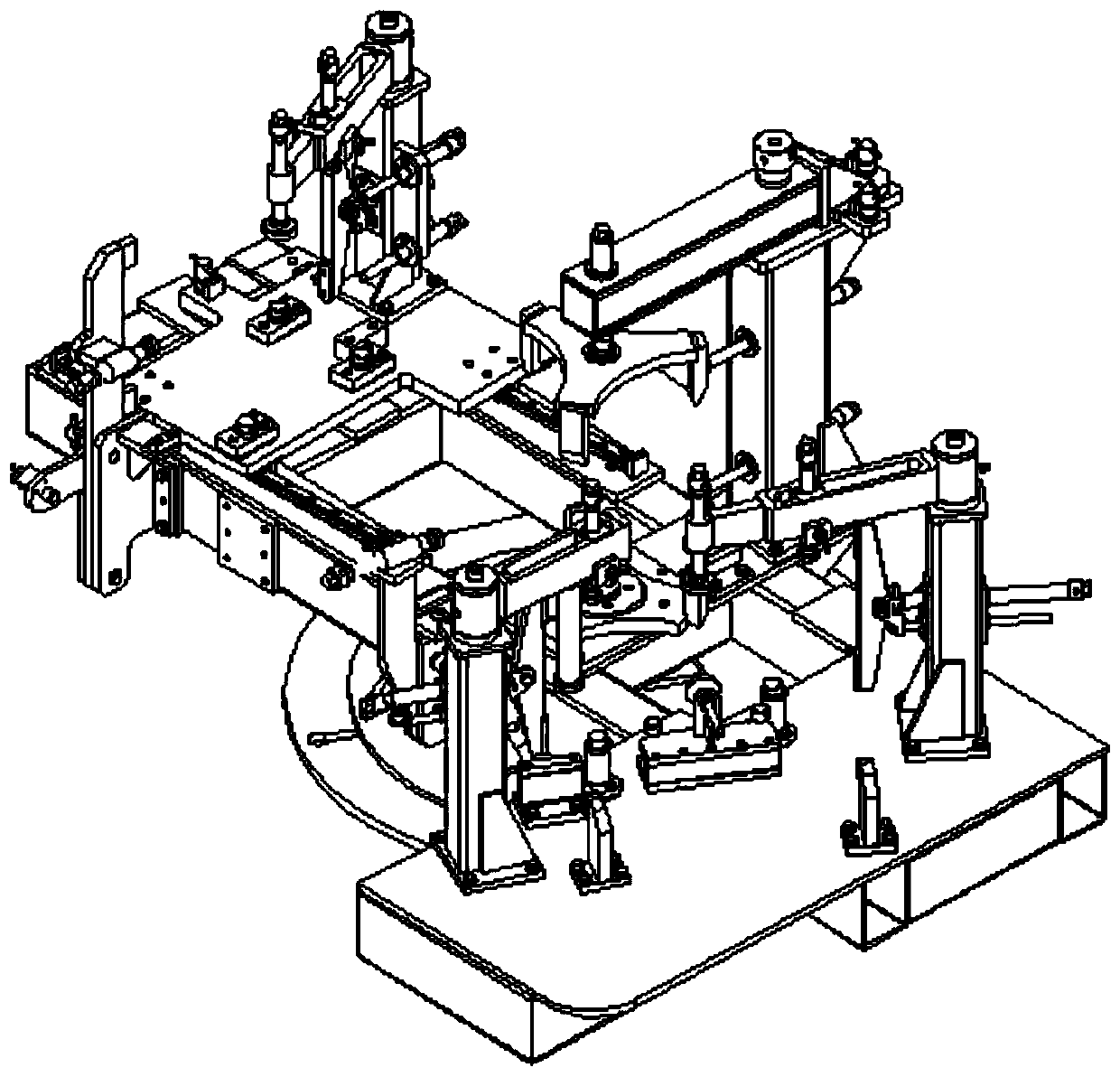

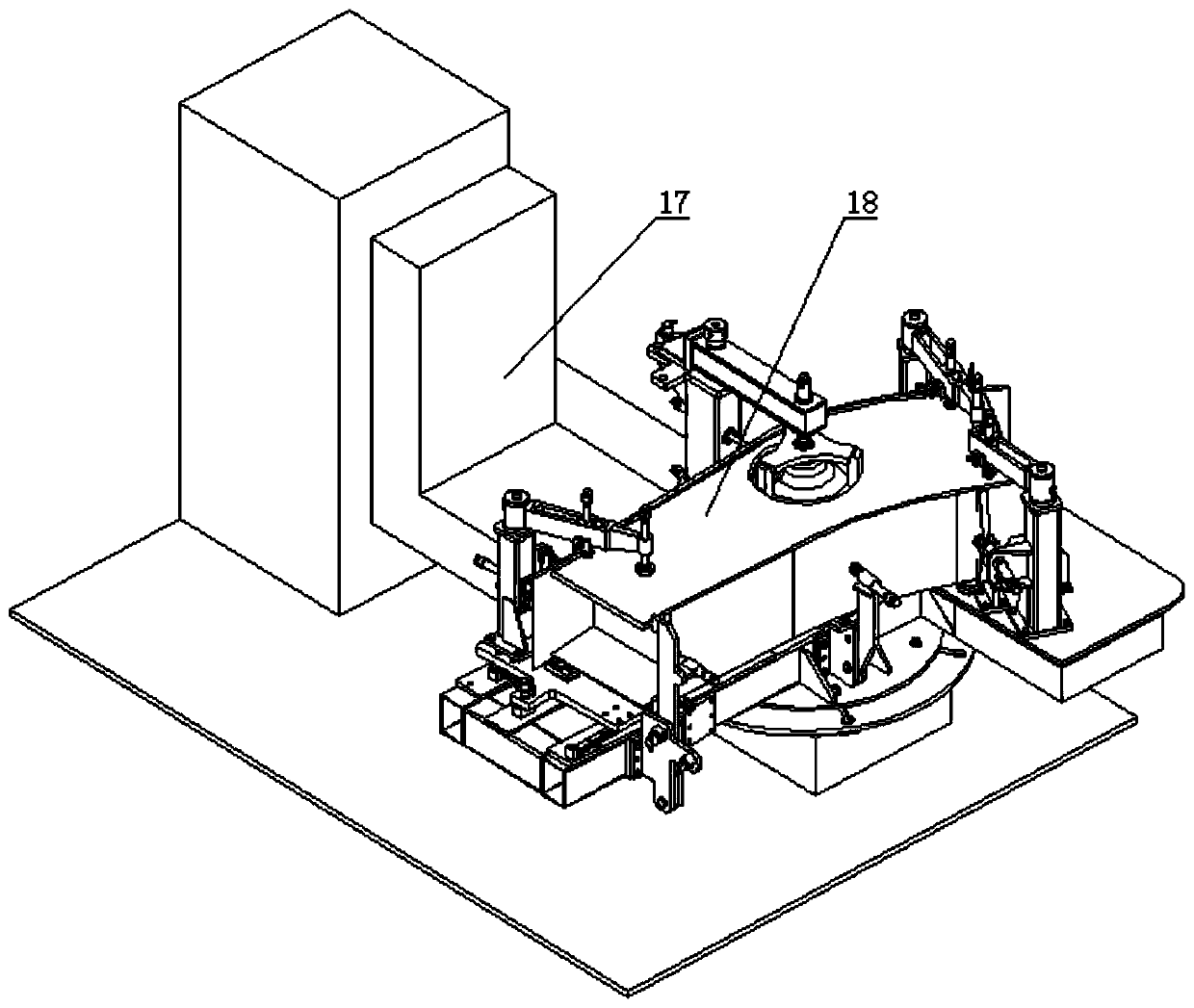

[0022] The invention relates to an installation device for group pairing of central box bodies of excavator booms, comprising a workbench 10, a movable positioning mechanism, a central positioning mechanism and a fixed positioning mechanism. Workbench is installed on the L type positioner 17.

[0023] The left side of the upper surface of the workbench is equipped with a movable positioning mechanism. The movable positioning mechanism includes a guide rail 16, a sliding plate 14, a lower bracket 15, a side positioning plate 13, a side pressure plate 3 and an upper pressing unit. The guide rail is installed on the working On the upper surface of the platform, a sliding plate is installed on the guide rail, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com