Positive electrode material of metal-air battery, and preparation method thereof

A metal-air battery and positive electrode material technology, applied in battery electrodes, fuel cell half-cells and secondary battery-type half-cells, nanotechnology for materials and surface science, etc., can solve the problem of low cycle life, charging Problems such as high energy consumption and hindering market applications can achieve the effect of improving adhesion, increasing contact area and space, and reducing electrode volume utility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Based on the above, the present invention provides a positive electrode material for a metal-air battery and a preparation method thereof, as well as a metal-air battery and a preparation method thereof. details as follows:

[0037] The positive electrode material of the metal-air battery provided by the embodiment of the present invention includes: a metal mesh structure substrate, a photocatalytic active material layer covering the surface of the metal mesh structure, and a co-catalyst supported on the photocatalytic active material layer nanoparticles.

[0038] The air electrode cathode material provided by the present invention uses a non-carbon self-supporting substrate, that is, a metal mesh structure substrate as the substrate. The air photocatalyst positive electrode can effectively improve the adhesion between the material and the substrate, and improve the mechanical stability of the material; secondly, the metal substrate can ensure a good conductor for elec...

Embodiment 1

[0072] 1. Preparation of TiO on the surface of titanium mesh by electrochemical positive oxidation method 2 nanotube array

[0073] in NH 4 The ethylene glycol solution prepared by dissolving F and deionized water in ethylene glycol is used as the electrolyte, and anodized at a working voltage of 30V for 1h to obtain TiO on the surface. 2 The titanium mesh of the nanotube array, after the anodic oxidation, the titanium mesh was thoroughly cleaned with deionized water, and ultrasonically oscillated, then dried at 60°C, and then calcined in air at 500°C for 3h;

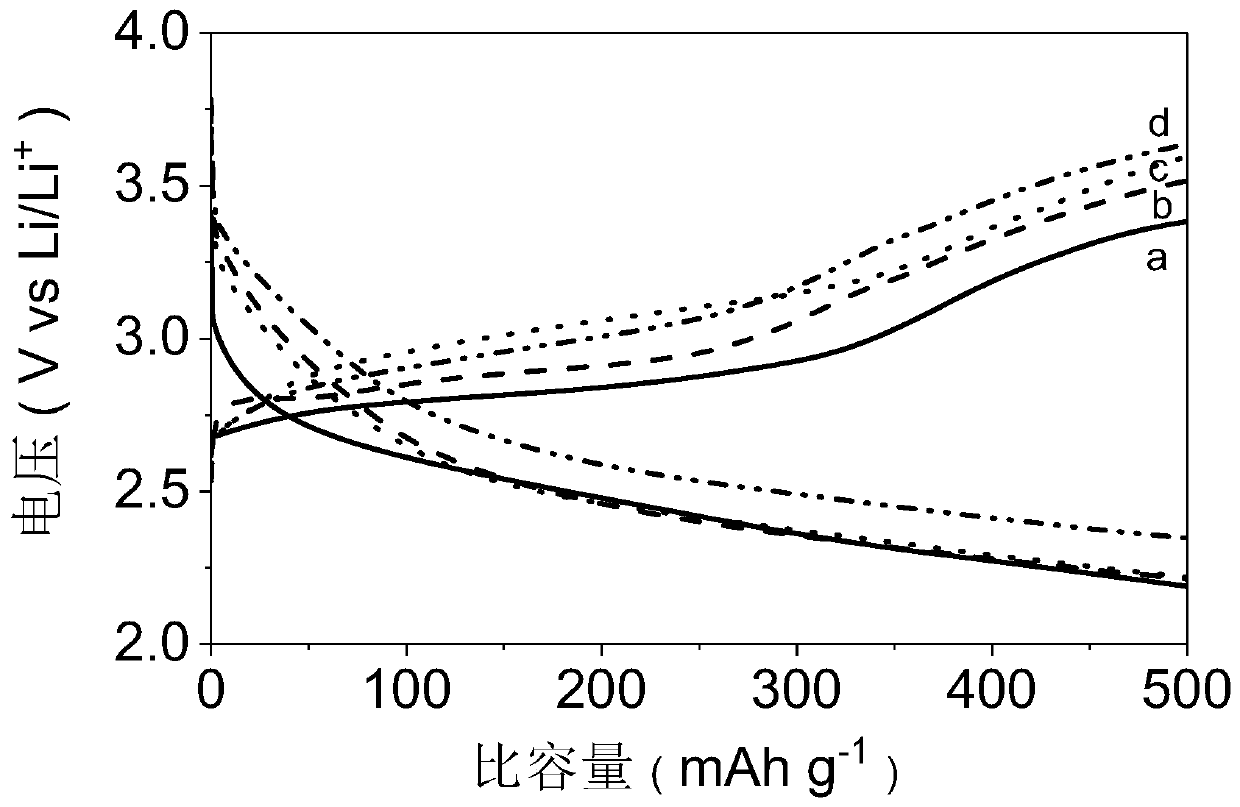

[0074] Prepared TiO 2 The morphology of the nanotube array is shown in figure 2 shown by figure 2 It can be seen that TiO with a porous structure was prepared on the titanium mesh 2 Nanotube arrays, compared with ordinary nanoparticle materials, can effectively increase the contact area and space between the material and the electrolyte, and at the same time provide sufficient deposition space for the discharge p...

Embodiment 2

[0082] 1. Ultrasonic wash the titanium mesh in a mixture of acetone-propanol (1:1, v / v, 30mL) for 30 minutes, then fully wash it with deionized water, and dry it in a nitrogen stream. Put the above-mentioned washed titanium mesh into a polytetrafluoroethylene liner filled with 2mL HF aqueous solution (0.1wt%), and react for a certain period of time at 140°C to obtain a non-carbon self-supporting titanium mesh-loaded TiO 2 nanoparticles.

[0083] 2. Using photocatalytic reduction deposition technology, the non-carbon self-supporting titanium mesh-loaded TiO obtained in step 1 2 The nanoparticle electrode sheet was placed in 0.3mM concentration of HAuCl 4 In the solution for 24 hours, and then irradiated by a 1000W Xe lamp for 90 minutes, a layer of gold nanoparticles can be deposited on the substrate as a cocatalyst;

[0084] 3. Take out the sample, wash it with deionized water, remove the solution or impurities adsorbed on the surface, and dry it at 70°C under vacuum;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com