Preparation method of multi-layer coating pole piece

A multi-layer coating and pole piece technology, which is applied in the field of preparation of lithium ion battery pole pieces, can solve the problems of uneven distribution of electrochemical reaction rate, inability to play the capacity normally, limited electron transfer speed, etc. The effect of transfer speed, high energy density, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

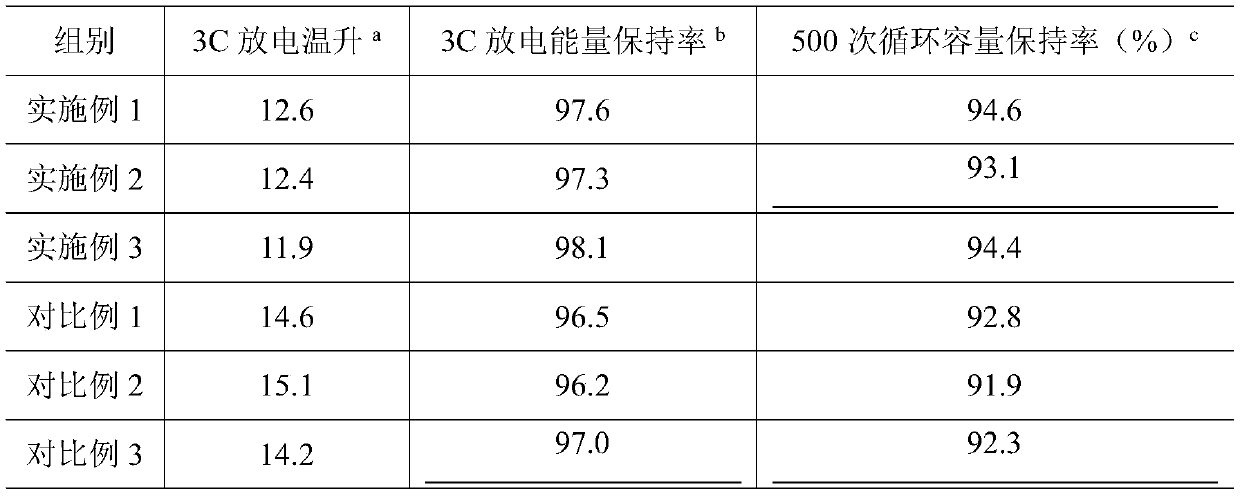

Examples

Embodiment 1

[0018] Positive sheet production: Lithium iron phosphate (positive electrode active material), conductive carbon black (conductive agent), polyvinylidene fluoride (PVDF) and NMP were respectively (97.5:1.3:1.2:80), (95:2.6:2.4: 80) and (92.5:3.9:3.6:80) were evenly mixed to obtain positive electrode slurry 1, positive electrode slurry 2 and positive electrode slurry 3. In this order, the slurry was uniformly coated on the aluminum foil in turn, and the coating thickness of each slurry was ensured to be the same, and the coating speed was controlled. After drying, winding, and rolling, a positive electrode sheet with a thickness of 180 μm was obtained.

[0019] Negative sheet production: Artificial graphite (negative active material), conductive carbon black (conductive agent), SBR and deionized water were respectively mixed with (97:1:2:90), (96:1.5:2.5:90), (94 : 2.5: 3.5: 90) were evenly mixed to obtain negative electrode slurry 1, negative electrode slurry 2 and negative el...

Embodiment 2

[0021] Positive plate production: different from Example 1, lithium iron phosphate (positive active material), conductive carbon black (conductive agent), polyvinylidene fluoride (PVDF) and NMP were respectively (97.1:1.5:1.4:80), The proportions of (94.2:3:2.8:80) and (92:4.5:3.5:80) were uniformly mixed to obtain positive electrode slurry 1, positive electrode slurry 2 and positive electrode slurry 3.

[0022] The rest are the same as in Embodiment 1, and will not be repeated here.

[0023] Negative sheet production: Different from Example 1, artificial graphite (negative electrode active material), conductive carbon black (conductive agent), SBR and deionized water were prepared in (96:1.6:2.4:90), (94.6:2.4: 3:90), (93.5:3:3.5:90) were evenly mixed to obtain negative electrode slurry 1, negative electrode slurry 2 and negative electrode slurry 3.

[0024] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0026] Positive plate production: different from Example 1, lithium iron phosphate (positive active material), conductive carbon black (conductive agent), polyvinylidene fluoride (PVDF) and NMP were respectively (96.8:1.6:1.6:80), The proportions of (93.6:3.2:3.2:80) and (92.4:3.8:3.8:80) were uniformly mixed to obtain positive electrode slurry 1, positive electrode slurry 2 and positive electrode slurry 3.

[0027] The rest are the same as in Embodiment 1, and will not be repeated here.

[0028] Negative plate production: different from Example 1, artificial graphite (negative active material), conductive carbon black (conductive agent), SBR and deionized water were prepared in (96.2:1.8:2:90), (94.2:2.8: 3:90), (92.4:3.6:4:90) were evenly mixed to obtain negative electrode slurry 1, negative electrode slurry 2 and negative electrode slurry 3.

[0029] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com