Electrode plate and preparation method thereof, and lithium ion battery

A technology for lithium-ion batteries and electrode pole pieces, which is applied to battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., and can solve the problems of increased cost of battery cell preparation, limited improvement in the conductivity of pole pieces, and broken belts. Achieve the effects of easy industrialized large-scale production, reduced weight ratio, and excellent specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

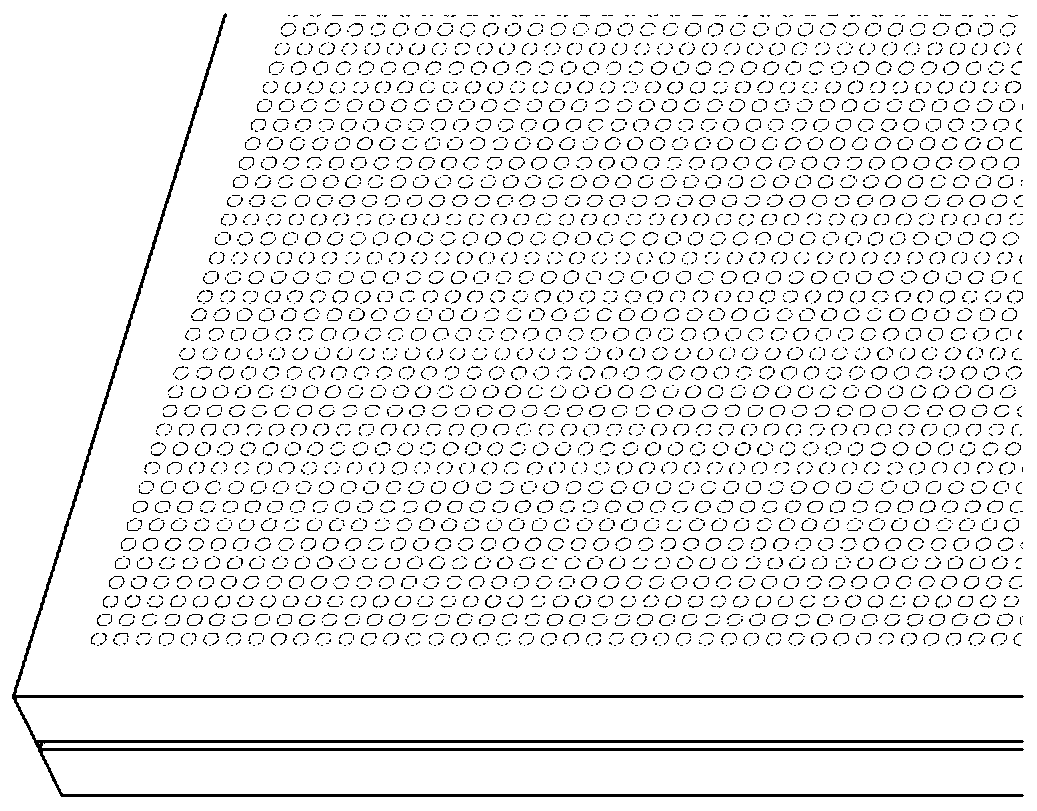

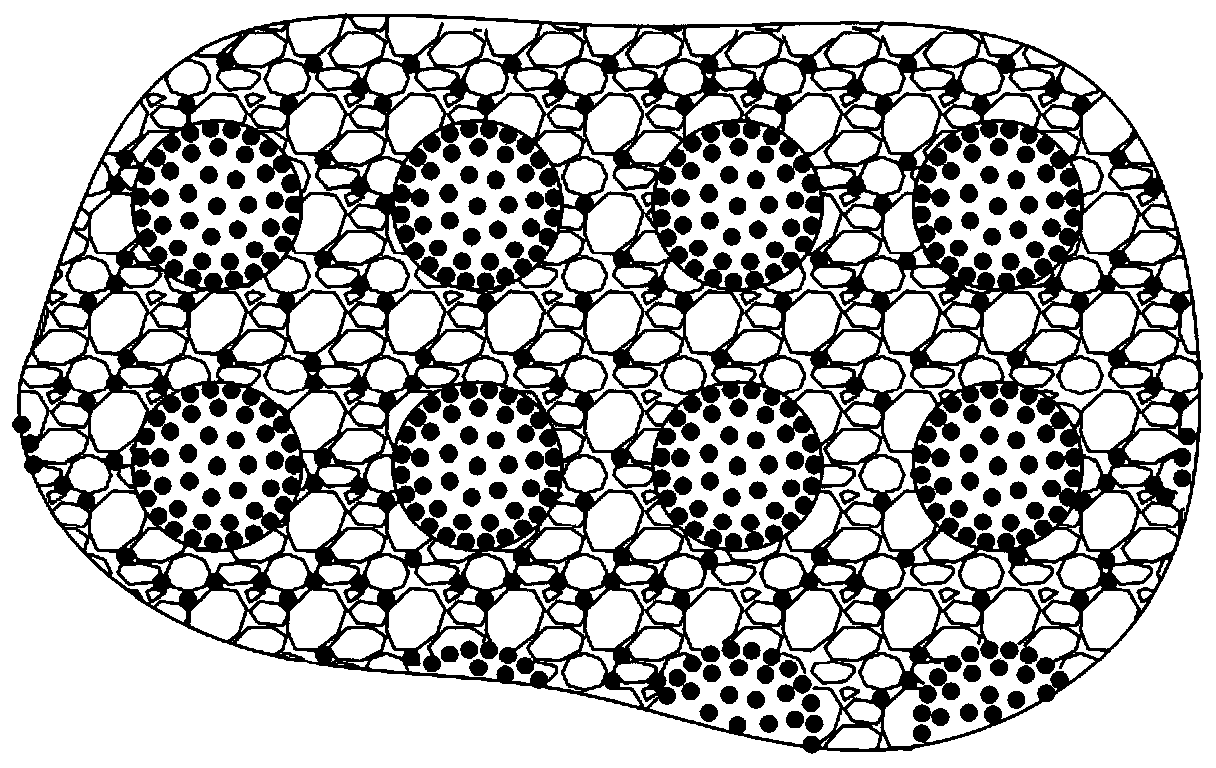

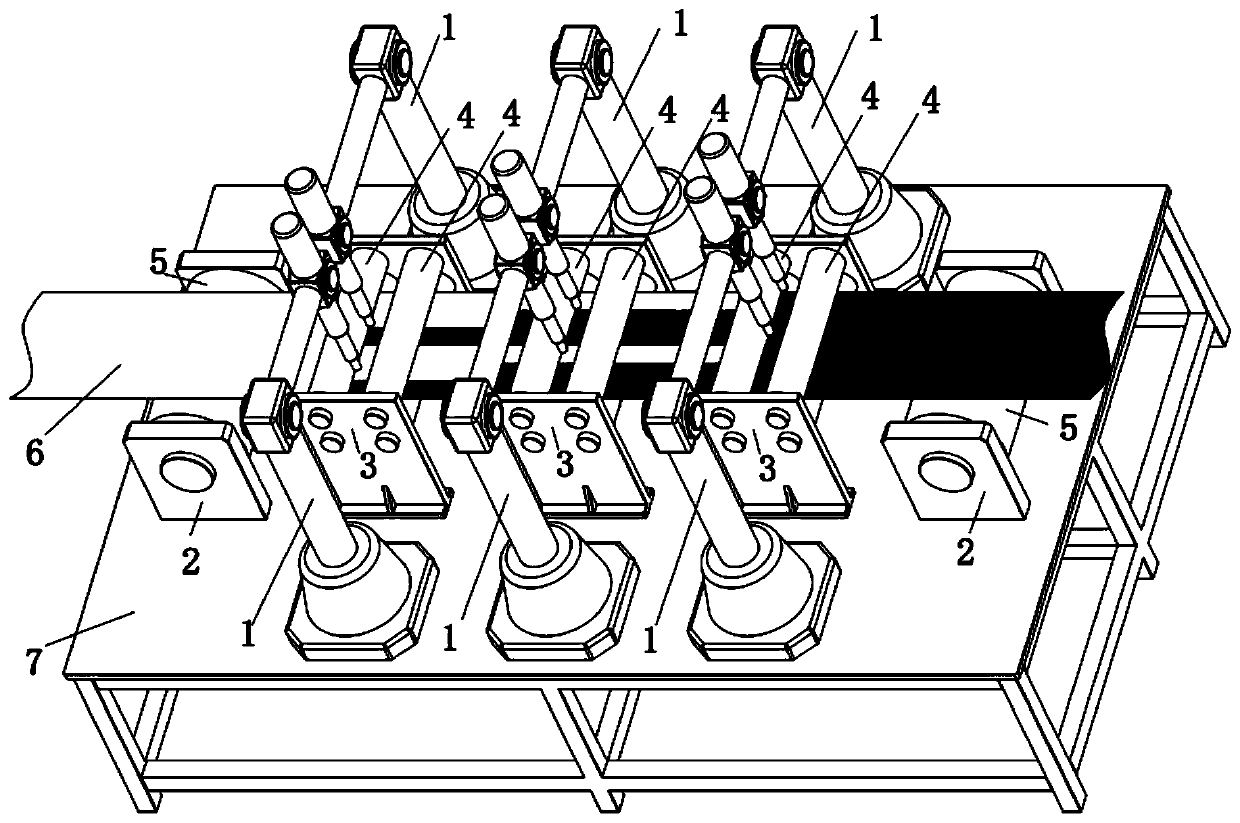

[0070] This embodiment provides an electrode pole piece, the electrode pole piece is a positive pole piece, the electrode pole piece includes a current collector and active material layers located on both sides of the current collector, and the thickness of the current collector of the electrode pole piece is is 0.02mm, and the pole piece thickness is 0.320mm. The current collector is aluminum foil, and the active material layer includes a positive electrode active material, a conductive agent and a binder, and the mass ratio of the conductive agent, active material and binder is 1.0:97:2.0; the positive electrode active material is lithium iron phosphate; the conductive agent is The combination of carbon nanotubes and graphene, the mass ratio of carbon nanotubes and graphene is 50:50, the diameter of the carbon nanotubes is 5-11nm, and the length of the tubes is 10-30 μm; the binding agent is PVDF (poly vinylidene fluoride). The electrode pole piece has holes on the active m...

Embodiment 2

[0078] The electrode sheet provided in this example has a thickness of 0.472mm, and the through hole penetrates the active material layer, and the coating surface density of each side of the current collector is 292g / m during preparation. 2 (Total coating density on both sides is 584g / m 2 ) except that others are identical to the electrode pole piece of embodiment 1 copper.

Embodiment 3

[0080] The electrode sheet provided in this example has a thickness of 0.625 mm, and the through hole penetrates the active material layer. The coating surface density of each side of the current collector is 389.5 g / m during preparation. 2 (Total coating density on both sides is 779g / m 2 ) except that others are identical to the electrode pole piece of embodiment 1 copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com