Manufacturing method of anode target, anode target, X-ray source and X-ray imaging system

A production method and anode target technology, applied in the field of X-rays, can solve the problems of long production cycle, high technical difficulty, low processing precision, etc., and achieve the effect of reducing production difficulty and solving production difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

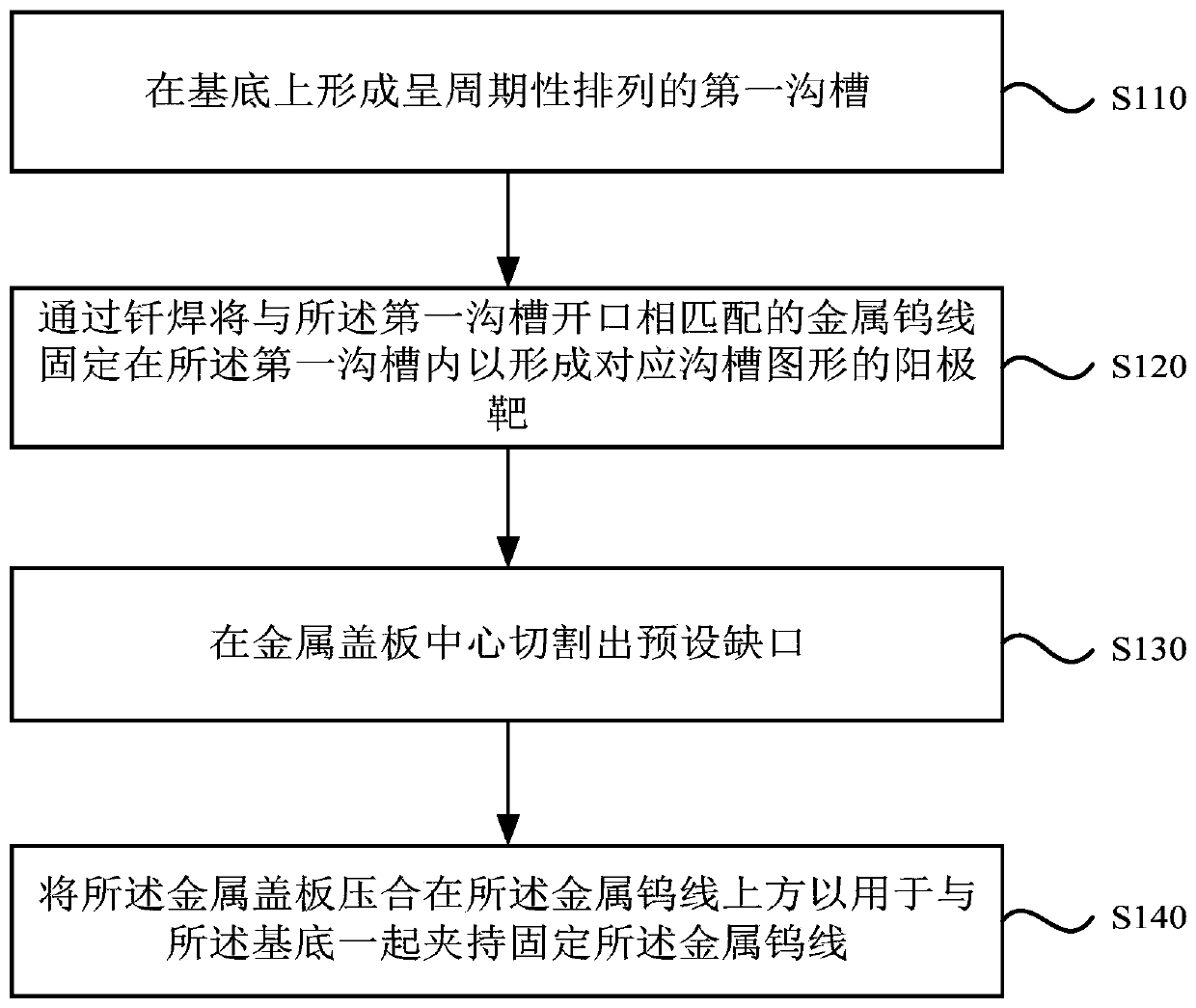

[0038] Such as figure 1 As shown, Embodiment 1 of the present invention provides a method for manufacturing an anode target, and the method for manufacturing an anode target includes:

[0039] S110, forming periodically arranged first trenches on the substrate.

[0040] In this embodiment, the material of the substrate can be made of a high-hardness material such as diamond. Preferably, the processing method for forming a plurality of first grooves in a periodic arrangement on the substrate includes plasma etching technology, precision mechanical cutting One of the technology or femtosecond laser processing technology.

[0041] Specifically, the periodically arranged first grooves include: grooves arranged in zigzag, zigzag or S shape; or a plurality of grooves arranged in parallel and at intervals. Wherein, the grooves arranged in zigzag, zigzag or S shape include: a plurality of first sub-grooves arranged in parallel along the first direction, a plurality of second sub-gro...

Embodiment 2

[0057] Such as Figure 8 As shown, Embodiment 2 of the present invention provides an anode target, which is manufactured using the method for manufacturing an anode target provided in Embodiment 1 of the present invention.

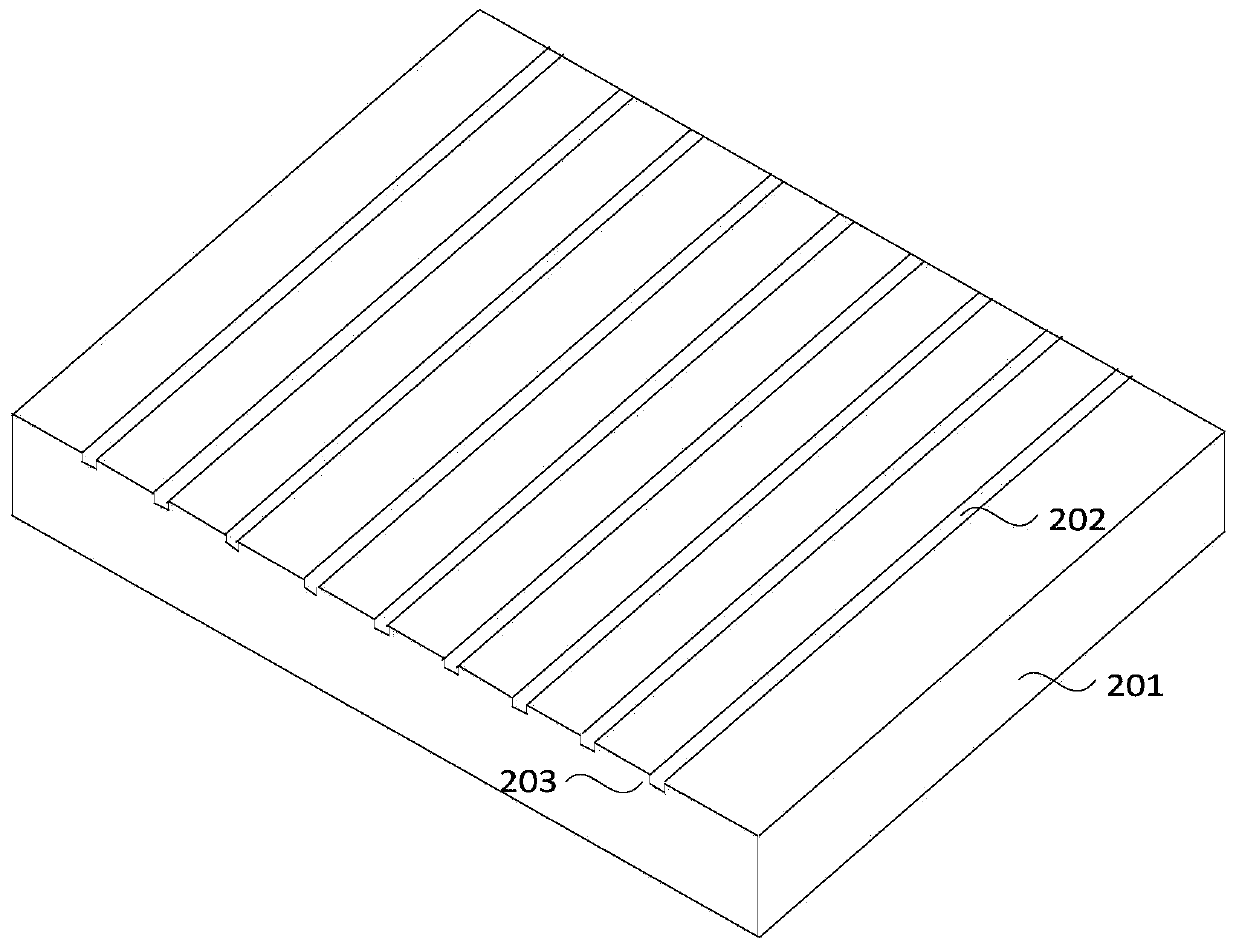

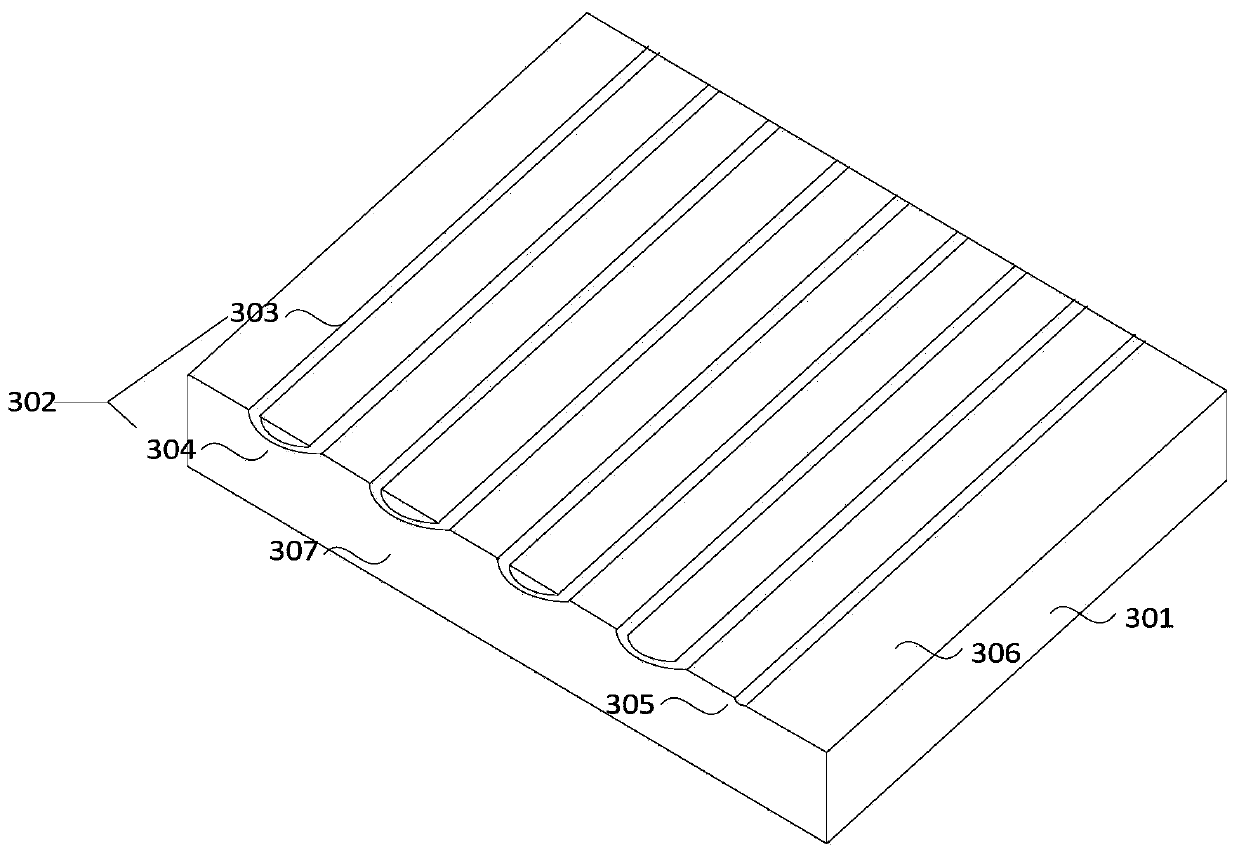

[0058] In one embodiment, the anode target includes a substrate 801 , a first groove 802 , and a metal tungsten wire 803 .

[0059] Specifically, the material of the substrate 801 can be made of a high-hardness material such as diamond. Preferably, the processing method for forming a plurality of first grooves 802 in a periodic arrangement on the substrate 801 includes plasma etching technology, precision mechanical One of cutting technology or femtosecond laser processing technology.

[0060] Specifically, the periodically arranged first grooves 802 include: grooves arranged in zigzag, zigzag or S shape, such as image 3 and Figure 4 shown; or multiple grooves arranged in parallel at intervals, such as figure 2 shown. Wherein, the grooves arranged ...

Embodiment 3

[0065] Such as Figure 9 As shown, Embodiment 3 of the present invention provides an X-ray source, which includes a cathode 905 , a high-voltage power supply 906 , a tube shell 907 , an anode 908 and a transmission window 910 .

[0066] In this embodiment, the anode 908 includes an anode substrate 901, an anode target 902 and an anode cap 909, the anode target 902 adopts the anode target provided in Embodiment 2 of the present invention, and the cathode 905 includes a cathode cover 911, a cathode filament lead 903 and a cathode filament 912 , the high voltage power supply 906 is electrically connected to the cathode 905 and the anode target 902 respectively, the cathode 905 and the anode 908 are sealed in a high vacuum tube shell 907 , and the transmission window 910 is set outside the anode 908 .

[0067] When using the X-ray source, turn on the high-voltage power supply 906, make the cathode filament 912 of the cathode 905 emit electrons through the cathode filament lead 903...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com