Multifunctional vacuum pump testing cover

A vacuum pump and test cover technology, which is applied in the field of vacuum pump testing, can solve the problems of single function, difficulty in ensuring the accuracy and reliability of test results, etc., and achieve the effects of improving accuracy, avoiding uneven pressure, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

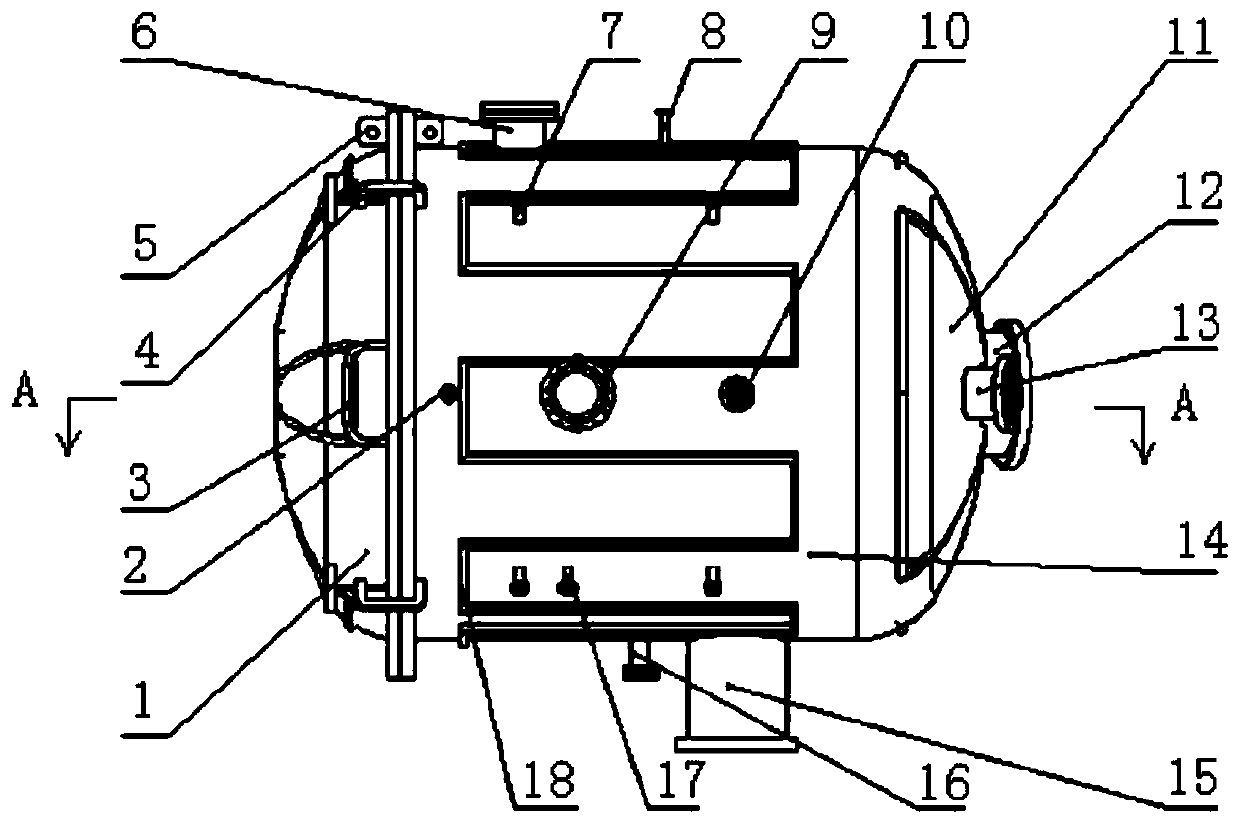

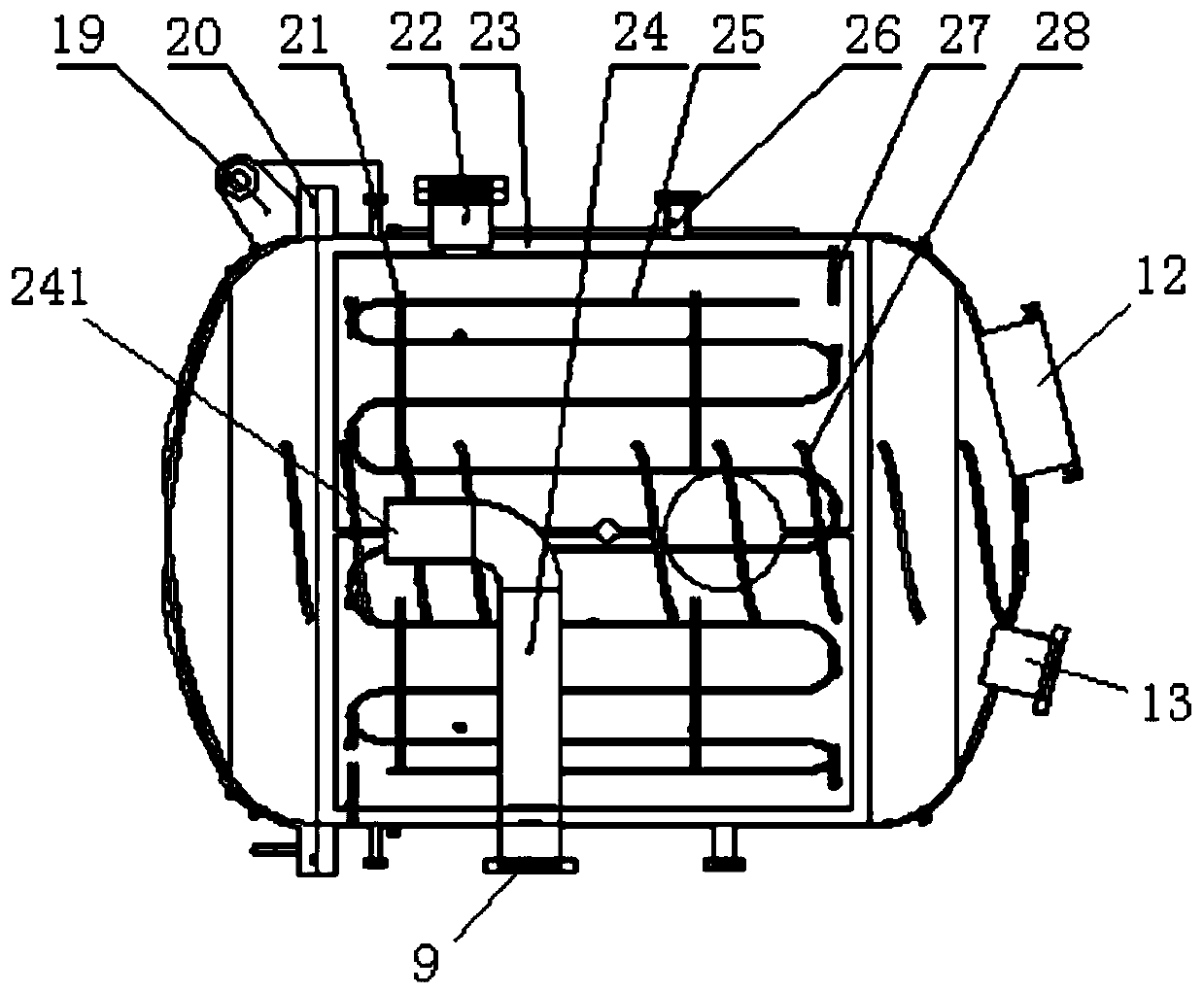

[0040] Such as Figure 1~2 As shown, the present embodiment provides a kind of internal volume is 1m 3 Horizontal multifunctional vacuum pump test cover, wherein one side of the casing 14 is provided with an openable first sealing cover 1, and the other side is fixed with a second sealing cover with the first pump port 12 to be tested and the second pump port 13 to be tested. Cover 11, the first sealing cover 1 and the second sealing cover 11 are both spherical, and due to the special gas environment of the vacuum in the vacuum test cover, the welding method of the second sealing cover 11 adopts the welding method of internal welding continuous welding, and Add external welding intermittent welding to the position where high strength is required to supplement the strength. In addition, in order to increase the water cooling area and improve the water cooling effect, the outer casing 14 and the first sealing cover 1 and the second sealing cover 11 are equipped with water coolin...

Embodiment 2

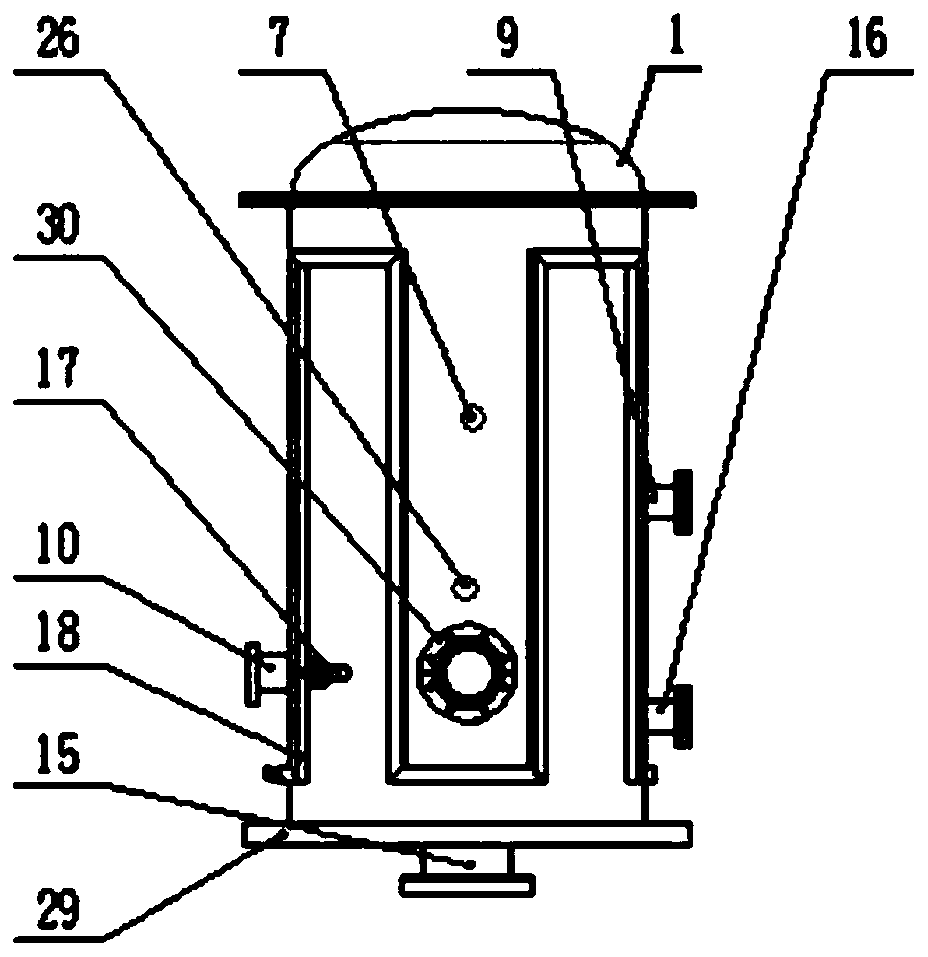

[0046] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is a vertical vacuum pump test cover with an inner volume of 100 L, and the main air suction port 15 must be located at the end of the shell 14 away from the first sealing cover 1 .

[0047] In this embodiment, the inner diameter D of the casing 14 is selected as 400mm according to the industry standard, and the end of the casing 14 away from the first sealing cover 1 is welded with a flange 29, and the main air inlet 15 is located in the middle of the flange 29, The arrangement of the water-cooling tubes 18 is based on the water-cooling capacity requirements, and only the water-cooling tubes 18 need to be arranged on the shell 14 , and the water-cooling tubes 18 do not need to be arranged on the first sealing cover 1 .

[0048] In this embodiment, in addition to the main suction port 15 and the coarse suction port 10, the plurality of suction ports also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com