Automatic mortar smearing device

A mortar and automatic technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of difficult to achieve brick surface control, uneven mortar volume, large hydraulic pressure, etc., to achieve stable mortar application quality and mortar utilization. The effect of high rate and small running impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

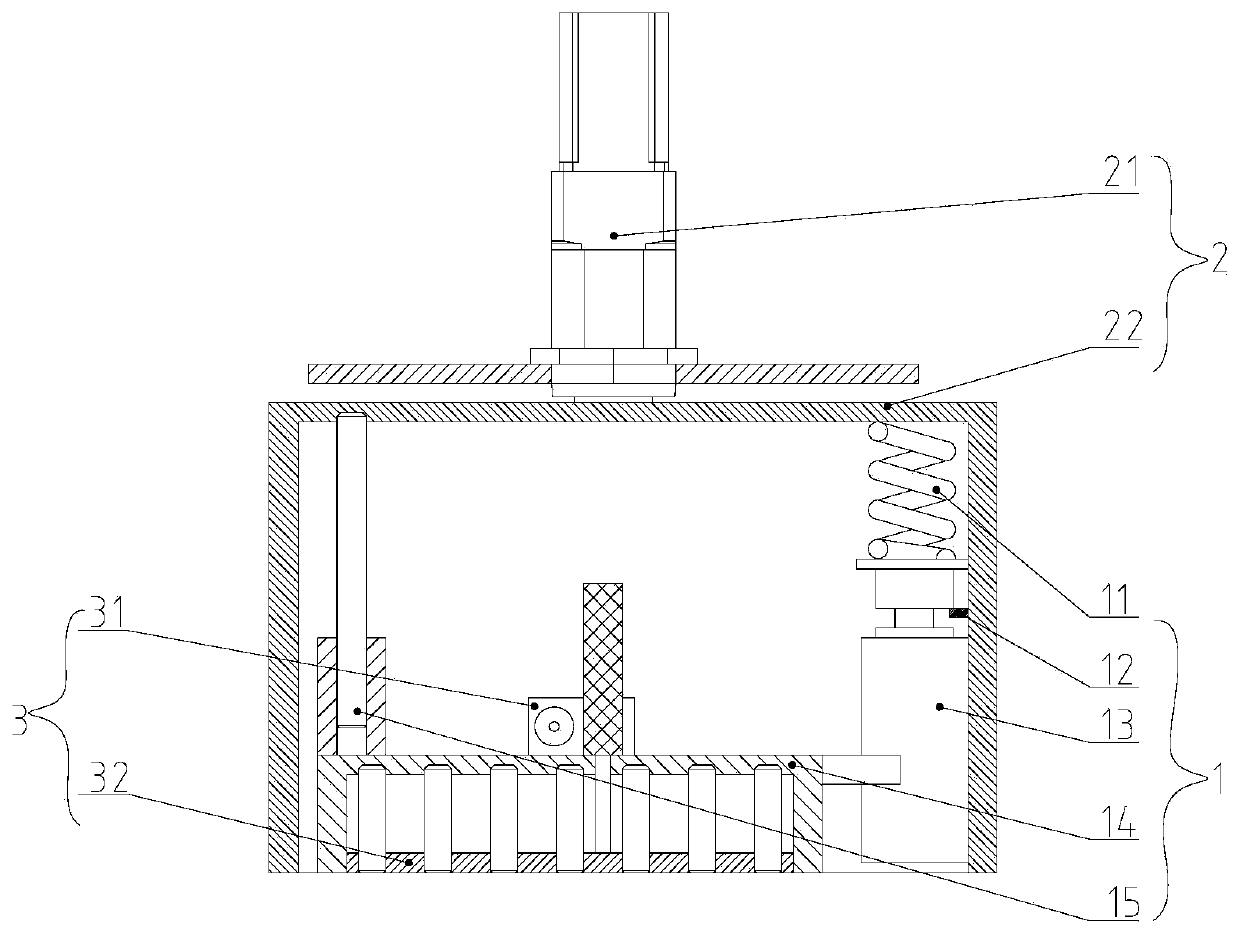

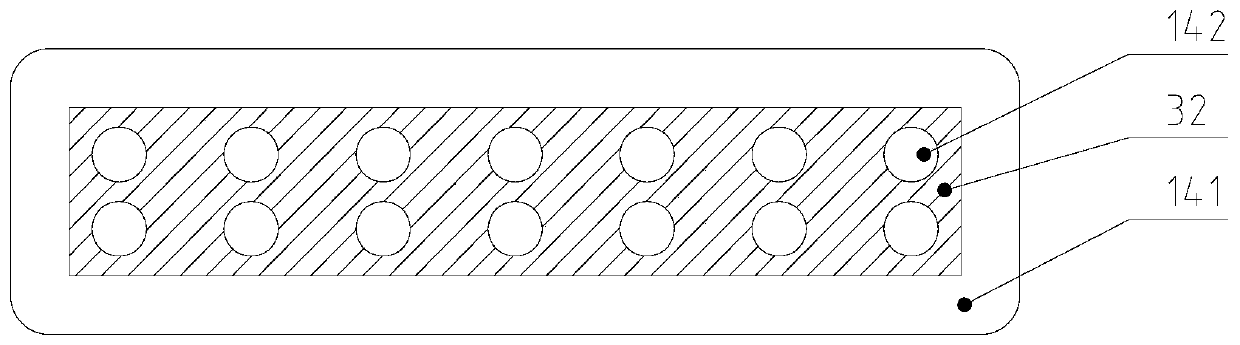

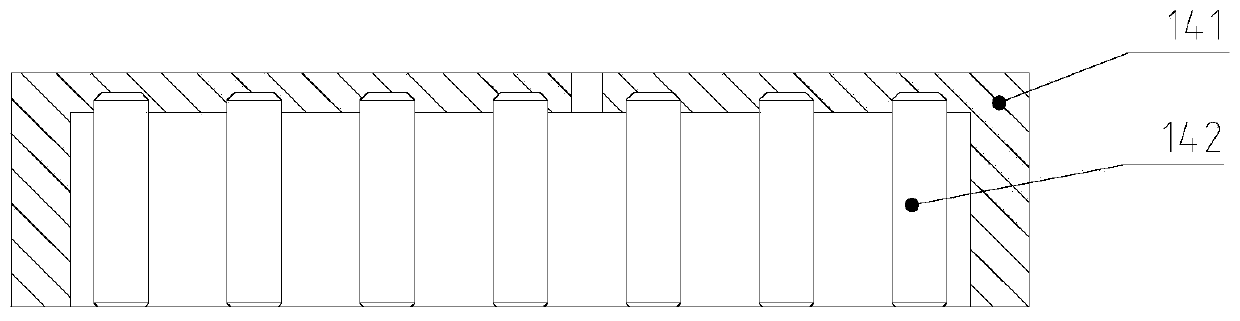

[0024] refer to figure 1 , this embodiment includes a profiling mechanism 1, a rotary mechanism 2 and an extrusion mechanism 3, and the profiling mechanism 1 includes a pre-compressed spring 11, a limit block 12, a first linear driver 13, a profiling die 14 and a first guide column 15 , the rotary mechanism includes a rotary driver 21 and a rotary housing 22 , and the extrusion mechanism includes a second linear driver 31 and a pressing plate 32 .

[0025] The first linear driver 13 is axially and vertically slidably connected with the inner wall of the rotary housing 22, the upper end of the first linear driver 13 is connected with the rotary housing 22 through the preload spring 11, and the output member of the first linear driver 13 is fixed to the molding die 14. even.

[0026] The first guide column 15 is fixed on the rotary housing 22 , and the first guide column 15 is slidably connected with the molding die 14 .

[0027] The first linear driver 13 drives the molding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com