Informationized and intelligent vibration grouting machine with adjustable vibration and controllable direction

A technology of grouting machine and vibration mechanism, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve problems such as long observation and evaluation time, delay in construction period, and untimely response to deformation, so as to ensure the quality of grouting and construction The effect of low cost and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

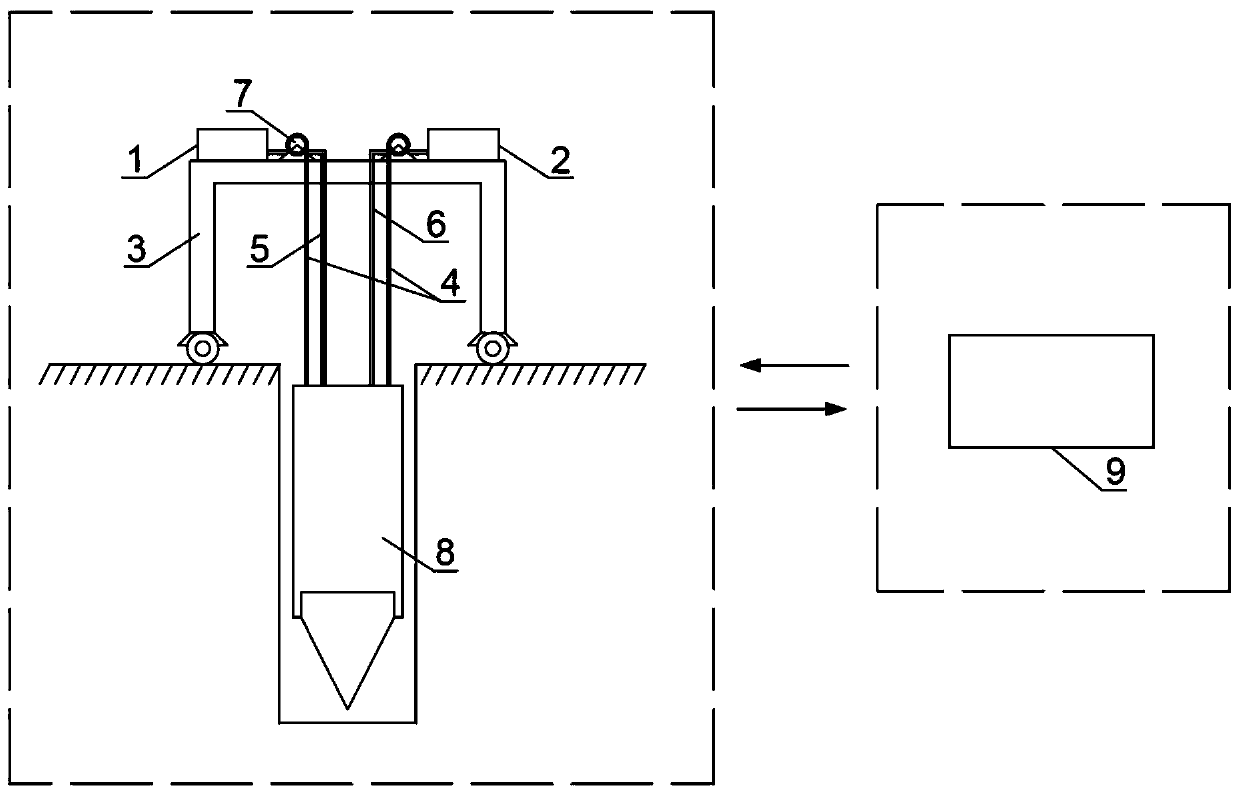

[0017] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, the present invention discloses an information-based intelligent vibration grouting machine with adjustable vibration and direction control, including a grouting pump 1, a hydraulic pump station 2, a grouting platform 3, a grouting tool 8, and a control front end 9 , two steel strands 4 and two pulleys 7; the upper end of the grouting platform 3 is fixed with a grouting pump 1, a hydraulic pump station 2 and two pulleys 7, and by controlling the remote operation of the front end 9, vibration, injection A fully automated intelligent grouting operation with integrated slurry; the two pulleys 7 are driven by the motor of the hydraulic pump station 2 (the two pulleys 7 are connected with the motor of the hydraulic pump station 2 through the rotating shaft installed inside the grouting platform 3) , the lower end of the grouting platform 3 is provided with casters, and the grouting platform 3 can move in all...

specific Embodiment approach 2

[0018] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of Embodiment 1. The casters are universal locking casters, which can move in all directions and are suitable for most grouting sites.

specific Embodiment approach 3

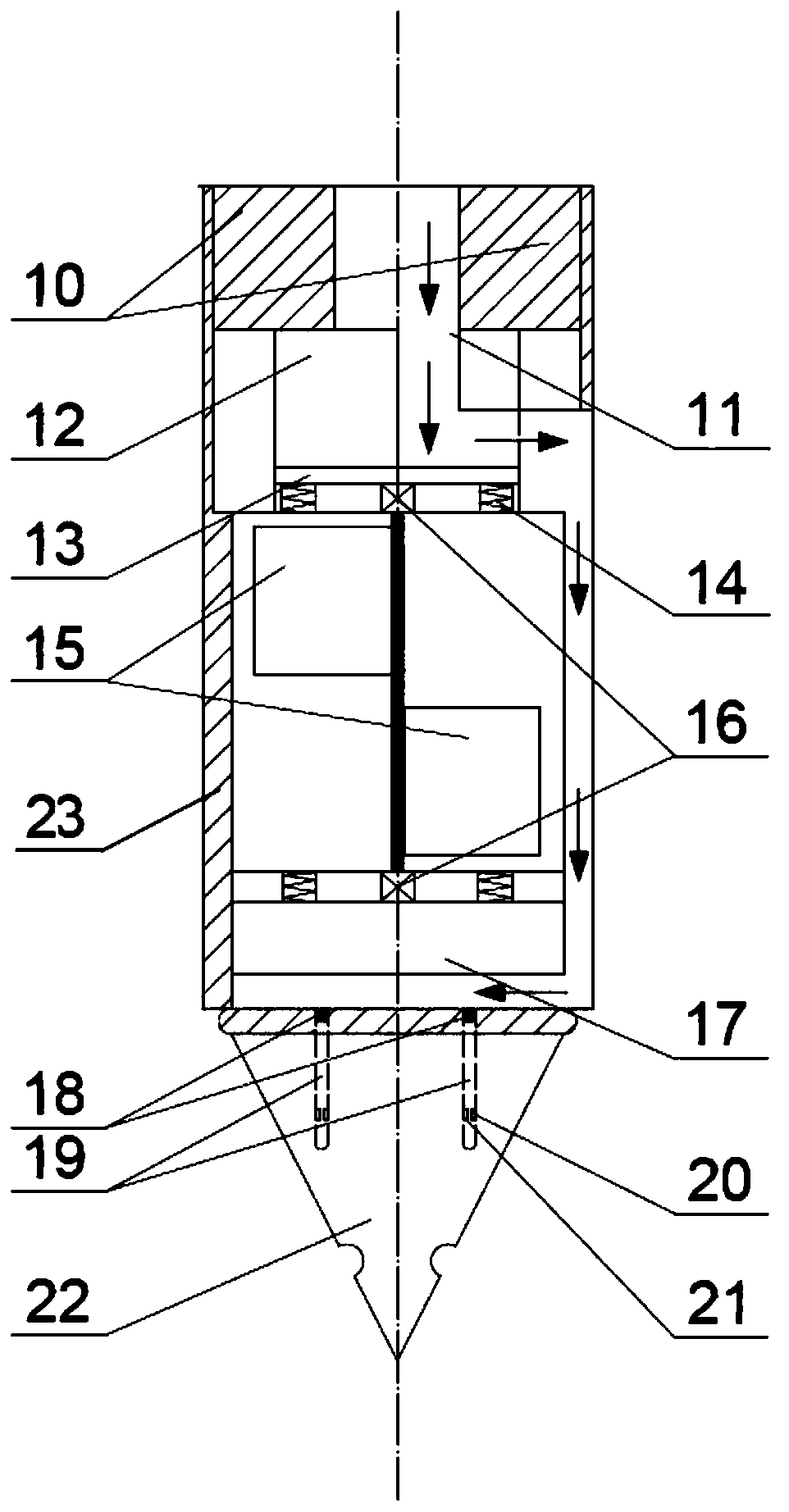

[0019] Specific implementation mode three: as figure 2 , 3 As shown, this embodiment is a further description of Embodiment 1. The vibration mechanism includes a housing 24, a rotating shaft 25 and two eccentric weights 15, and the rotating shaft 25 and the two eccentric weights 15 are all arranged in the housing 24, the rotating shaft 25 is vertically arranged and is fixed with two eccentric blocks 15 from top to bottom. The upper end of the rotating shaft 25 is connected to the middle part of the oil storage bin 13 through the supporting bearing 16, and the lower end of the rotating shaft 25 is connected to the wireless transmission through the supporting bearing 16. The module 17 is rotationally connected, and the upper and lower ends of the housing 24 are elastically connected to the counterweight 10 and the wireless transmission module 17 through two springs 14 respectively. The vibrating mechanism is a horizontal vibrator, and the horizontal eccentric vibrating mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com