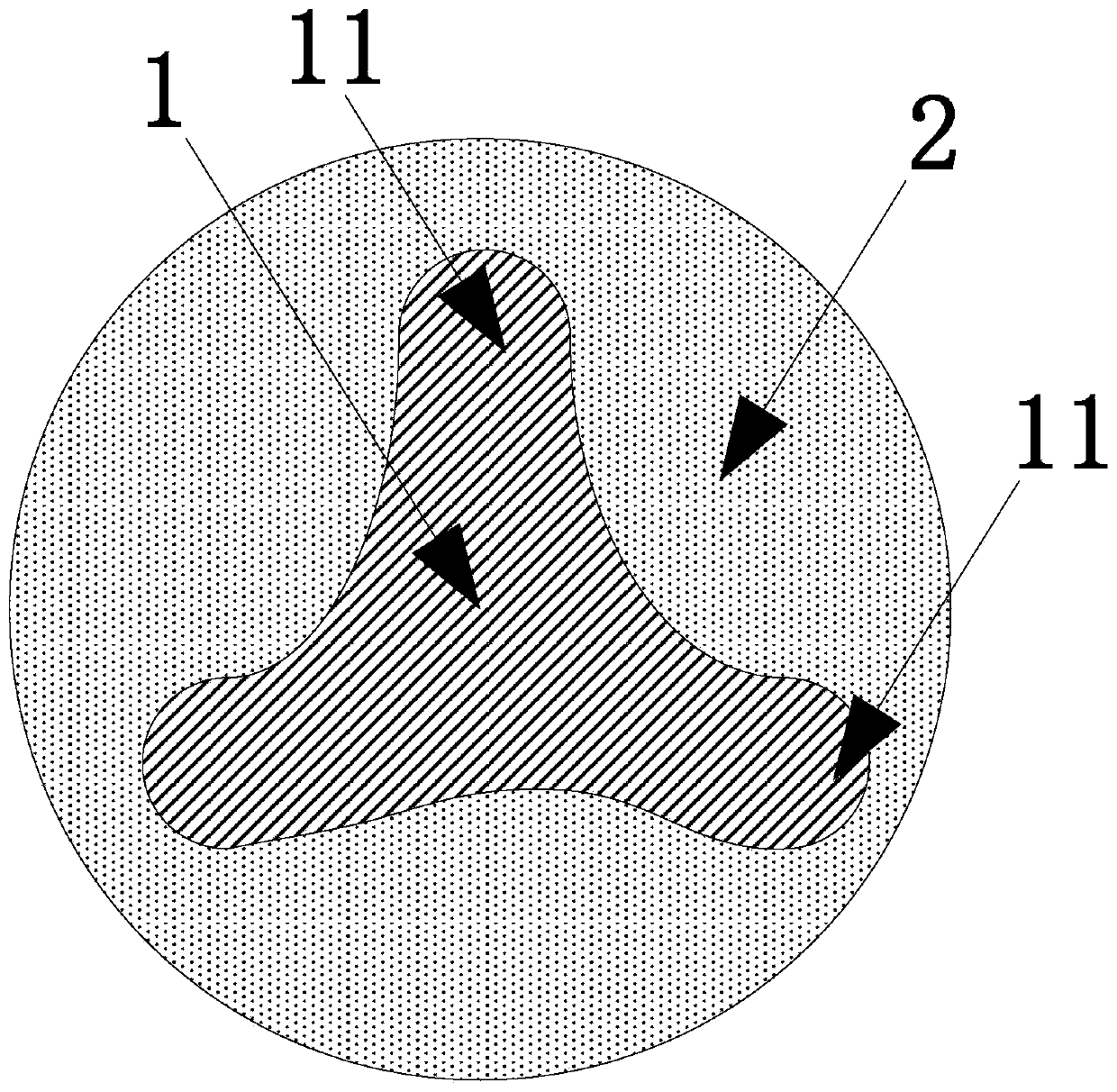

Antibacterial conductive fiber and preparation method thereof

A conductive fiber and fiber technology, which can be used in conductive/antistatic filament manufacturing, fiber processing, fiber chemical characteristics, etc., and can solve problems such as inability to meet antistatic requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In this example, the following method is used to prepare antibacterial conductive fibers:

[0058] (A) Preparation of cortical resin matrix: PBT slices with a relative viscosity of 1.2 are added to the mill, the gap between the cutter discs is adjusted to 1.5mm, and cooling water at 6°C is used to grind at 3800rpm to obtain the particle size 40-60 mesh PBT powder, the bulk density of the PBT powder is 0.70g / ml;

[0059] (B) mixed antibacterial composition and cortex resin powder: will account for the copper powder (200nm) of 1.2wt% in cortex gross mass, the passivator Irganox MD 1024 of 1.0wt%, the auxiliary antioxidant Irgafox168 of 1.0wt%, 1.0 The antioxidant Irgafox 1098 of wt%, the lubricant polyethylene wax of 0.1wt% and PBT powder are added in the high-speed mixer, after stirring for 5 minutes under the condition of stirring speed 400rpm, adjust the stirring speed to 850rpm and continue to stir for 30 seconds, Release about 1 / 3 of the pre-dispersion from the bott...

Embodiment 2

[0067] In this example, the following method is used to prepare antibacterial conductive fibers:

[0068] (A) Preparation of cortical resin matrix: Add PET slices with a relative viscosity of 1.2 into the mill, adjust the gap between the cutter discs to 1.5mm, use 8°C cooling water, and grind under the condition of 3800rpm to obtain the particle size 50-70 mesh PET powder, the bulk density of the PET powder is 0.65g / ml;

[0069] (B) mixed antibacterial composition and cortex resin powder: will account for the copper chloride of 0.45wt% of the total mass of the cortex, the passivator Irganox 1076 of 0.1wt%, the auxiliary antioxidant Irgafox B 225 of 0.05wt%, 0.5wt% % antioxidant Irgafox 1010, 0.7% lubricant barium stearate, 0.8% lubricant sodium stearate and PET powder are added in the high-speed mixer, and after stirring for 5 minutes under the condition of stirring speed 400rpm, adjust Continue to stir for 30 seconds at a stirring speed of 850 rpm, release about 1 / 3 of the p...

Embodiment 3

[0077] In this example, the following method is used to prepare antibacterial conductive fibers:

[0078] (A) Preparation of cortical resin matrix: PBT slices with a relative viscosity of 1.2 are added to the mill, the gap between the cutter discs is adjusted to 1.5mm, and cooling water at 6°C is used to grind at 3800rpm to obtain the particle size 40-60 mesh PBT powder, the bulk density of the PBT powder is 0.70g / ml;

[0079] (B) mixed antibacterial composition and cortex resin powder: will account for the copper powder (200nm) of 0.8wt% of cortex gross mass, the copper molybdate of 0.2wt%, the passivator Irganox MD 1024 of 0.5wt%, 0.6wt% Auxiliary antioxidant Irgafox168, 0.05wt% antioxidant Irgafox 1098, 0.4% lubricant paraffin, 0.3% lubricant calcium stearate and PBT powder are added in the high-speed mixer, under the condition of stirring speed 400rpm After stirring for 5 minutes, adjust the stirring speed to 850rpm and continue to stir for 30 seconds, release about 1 / 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com