System for capturing semi-volatile heavy metal in zinc-containing solid waste through high-temperature separation in cooperation with ammonium complexation

A semi-volatile, heavy metal technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of high cost, corrosion, unpublished crude zinc oxide, etc., and achieve the effect of increasing the concentration and reducing the amount of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

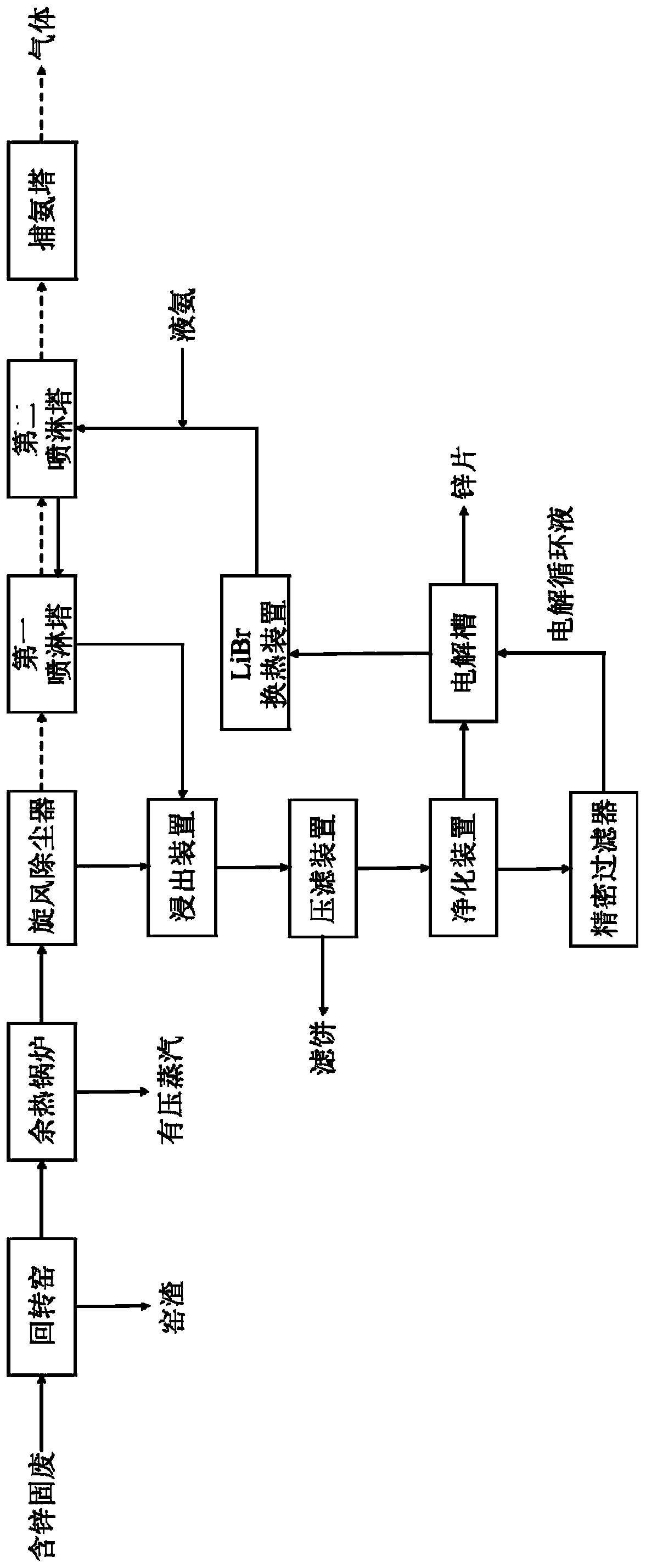

[0041] This embodiment provides a system for high-temperature separation and ammonium network capture of semi-volatile heavy metals in zinc-containing solid waste. The system includes a pre-processing unit, a gas processing unit, and a solid processing unit;

[0042] The pretreatment system includes a reduction and oxidation device and a gas-solid separation device connected in sequence, the gas outlet of the gas-solid separation device is connected to the gas processing unit, and the solid outlet of the gas-solid separation device is connected to the solid processing unit connected;

[0043] The solid processing unit includes a leaching device, a purification device and an electrolysis device connected in sequence;

[0044] The gas processing unit includes a gas absorption device, the absorption liquid inlet of the gas absorption device is connected with the electrolyte outlet of the electrolysis device, and the absorption liquid outlet of the gas absorption device is connect...

Embodiment 2

[0046] This example provides a system for high-temperature separation and ammonium network capture of semi-volatile heavy metals in zinc-containing solid waste. Its structure is as follows figure 1 As shown, the system includes a pre-processing unit, a gas processing unit and a solid processing unit;

[0047] The pre-treatment system includes a rotary kiln, a waste heat boiler and a cyclone dust collector connected in sequence, the gas outlet of the cyclone dust collector is connected to the gas processing unit, and the solid outlet of the gas-solid separation device is connected to the solid processing unit connected;

[0048]The solid processing unit includes a leaching device, a purification device and an electrolysis device connected in sequence;

[0049] The gas processing unit includes a gas absorption device, the absorption liquid inlet of the gas absorption device is connected with the electrolyte outlet of the electrolysis device, and the absorption liquid outlet of ...

Embodiment 3

[0055] This example provides a method for using the system provided in Example 2 for high-temperature separation and ammonium network capture of semi-volatile heavy metals in zinc-containing solid waste. The method includes:

[0056] After the zinc-containing solid waste is reduced by the rotary kiln, the semi-volatile heavy metals mainly composed of zinc volatilize to form soot, which is then oxidized into heavy metal oxides. After passing through the waste heat boiler, the soot mainly composed of zinc oxide enters the cyclone dust collector to collect large particles of soot, and then directly enters the two-stage spray tower, where heavy metal oxides, sulfur dioxide and carbon dioxide are absorbed by electrolytic circulating fluid. The first spray tower uses the electrolytic circulation liquid from the second spray tower for spraying, and the electrolytic circulation liquid used in the second spray tower comes from the outlet of the electrolytic cell. The electrolyte at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com