Manufacturing process of ultrahigh-strength fastener

A manufacturing process, ultra-high-strength technology, applied in the direction of manufacturing tools, threaded fasteners, connecting components, etc., can solve problems such as dependence on imports, and achieve strategic significance, foreign exchange savings, and cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

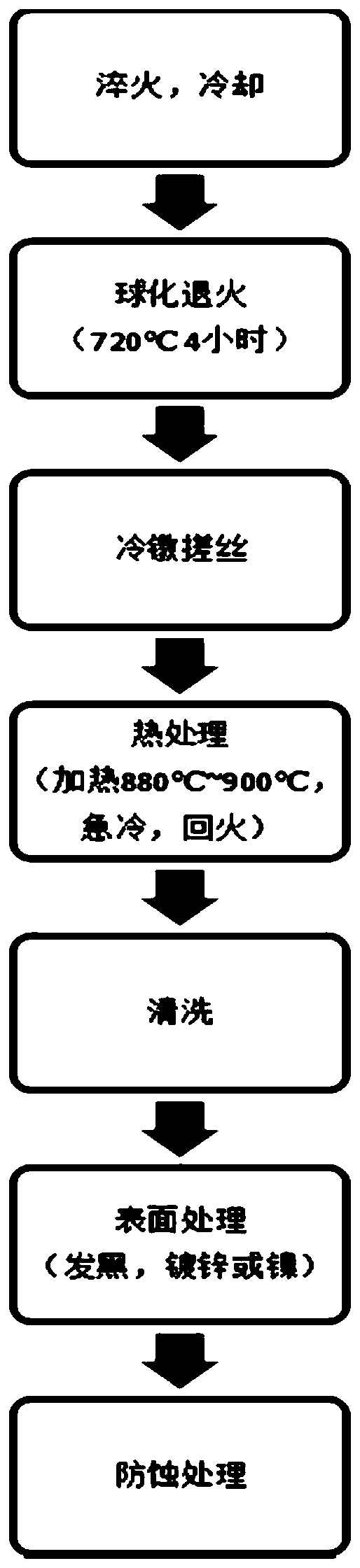

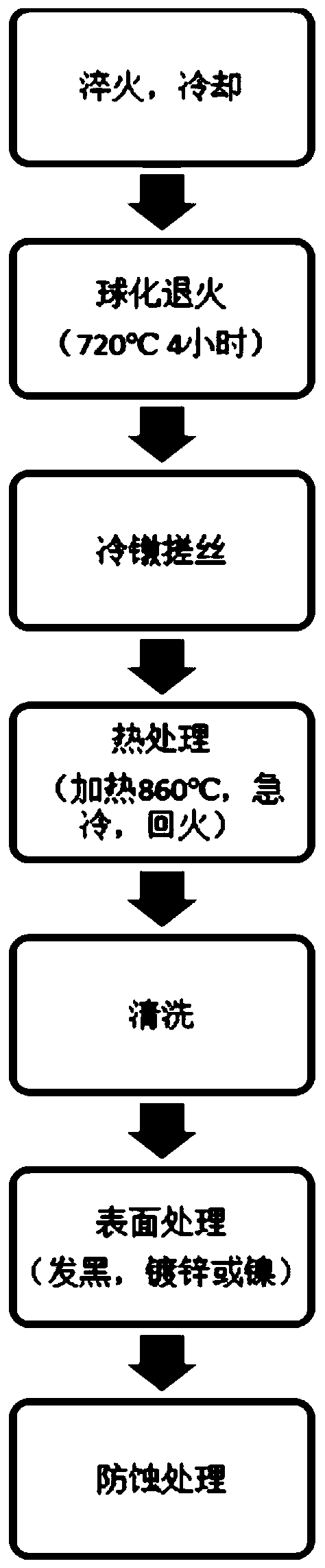

[0017] Such as figure 1 , specifications below M12, the material is 20Mn2 steel;

[0018] When heating in a salt bath furnace, the quenching heating temperature is controlled at 880°C to 900°C;

[0019] After spheroidizing annealing (isothermal at 720°C for 4 hours), it is cooled to below 500°C with the furnace and then air-cooled.

[0020] Quenching out of the furnace; after being out of the furnace, the work body can be scattered on the wire grid, and the wire grid is quenched into the water together. When the hissing sound is about to end, take out the grid (the workpiece is about 200-300°C at this time) and air cool.

[0021] Cold heading thread rolling;

[0022] Tempering treatment: The workpiece that has been thoroughly cooled in the air should be tempered in time, and the tempering temperature depends on the steel

[0023] The upper limit or the lower limit of the manganese content and carbon content in the composition depends. Generally controlled at 360±20°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com