Low-temperature ceramic flame-retardant functional master batch and preparation method thereof

A technology of functional masterbatch and low-temperature ceramics, which is applied in the field of low-temperature ceramic flame-retardant functional masterbatch and its preparation, which can solve the problems of poor coverage, high damage rate, and non-compact carbon layer structure of ceramic formation, and achieve low smoke emission rate , smooth surface, low smoke toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

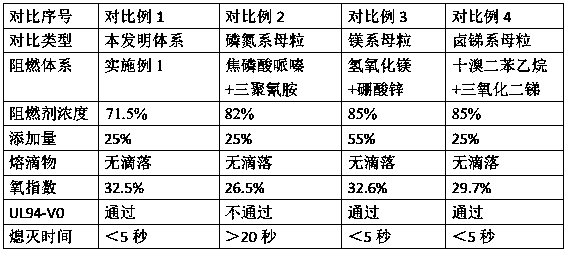

Examples

Embodiment 1

[0037] This embodiment provides a low-temperature ceramic flame retardant functional masterbatch, which includes the following components:

[0038] 5 kg of dimethyl silicone rubber, 10 kg of methyl vinyl silicone rubber, 8 kg of silicone resin, 5 kg of aluminum diethyl hypophosphite, 2.5 kg of glass microspheres, 2 kg of montmorillonite, 20 kg of natural bone meal, and 42 kg of synthetic ceramic bone meal , coupling agent 1.5kg, dispersant EVA wax 2kg, lubricant EBS2 kg.

[0039] Wherein, the silicone resin is a powdered silicone resin with a silicon content of 70-99% and a particle size of less than 5um.

[0040] The main chains of the dimethyl silicone rubber and the methyl vinyl silicone rubber are composed of silicon and oxygen atoms alternately, and two or more organic groups are connected to the silicon atoms.

[0041] The particle size of the montmorillonite is lower than 3um;

[0042] The natural bone powder is bone charcoal powder made from bovine bone and horse bon...

Embodiment 2

[0054] This embodiment provides a low-temperature ceramic flame retardant functional masterbatch, which includes the following components:

[0055] 10kg of dimethyl silicone rubber, 15kg of methyl vinyl silicone rubber, 12kg of silicone resin, 2kg of aluminum diethyl hypophosphite, 2kg of glass beads, 5kg of montmorillonite, 16kg of natural bone meal, 32 kg of synthetic ceramic bone meal, Joint agent 2kg, dispersant EVA wax 2.5kg, lubricant EBS1.5kg.

[0056] Wherein, the silicone resin is a powdered silicone resin with a silicon content of 70-99% and a particle size of less than 5um.

[0057] The main chains of the dimethyl silicone rubber and the methyl vinyl silicone rubber are composed of silicon and oxygen atoms alternately, and two or more organic groups are connected to the silicon atoms.

[0058] The particle size of the montmorillonite is lower than 3um;

[0059] The natural bone powder is bone charcoal powder made from bovine bone and horse bone, and the particle s...

Embodiment 3

[0072] This embodiment provides a low-temperature ceramic flame retardant functional masterbatch, which includes the following components:

[0073] 10kg of dimethyl silicone rubber, 12kg of methyl vinyl rubber, 15kg of silicone resin, 4kg of aluminum diethyl hypophosphite, 2kg of glass beads, 2 kg of montmorillonite, 17kg of natural bone meal, 34 kg of synthetic ceramic bone meal, Joint agent 1.5kg, dispersant EVA wax 1.5kg, lubricant EBS1kg.

[0074] Wherein, the silicone resin is a powdered silicone resin with a silicon content of 70-99% and a particle size of less than 5um.

[0075] The main chains of the dimethyl silicone rubber and the methyl vinyl silicone rubber are composed of silicon and oxygen atoms alternately, and two or more organic groups are connected to the silicon atoms.

[0076] The particle size of the montmorillonite is lower than 3um;

[0077] The natural bone powder is bone charcoal powder made from bovine bone and horse bone, and the particle size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com