Preparation method of BR/SBR/tread reclaimed rubber/rubber powder combined autotruck tire flap

A technology for trucks and reclaimed rubber is applied in the field of preparation of automobile tire pads, which can solve problems such as the overall scrapping of tires, and achieve the effects of reducing dust, good mechanical properties, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] In this example, the vulcanization system used is sulfur vulcanization system, the rubber powder used is 60 mesh tread rubber powder, the specific formula is: BR 10 parts, SBR 10 parts, tread reclaimed rubber 80 parts, 60 mesh tread rubber 5 parts powder, 1.9 parts zinc oxide, 0.9 parts stearic acid, 0.3 parts RD, 0.3 parts 4010NA, 6.3 parts N330, 0.9 parts naphthenic oil, 0.72 parts S, 0.54 parts CZ, 0.36 parts DM.

[0024] In this example, the BR / SBR / reclaimed rubber / rubber powder is used with truck tire cushion belt, and the preparation steps are as follows:

[0025] 1. Put 10 parts of BR, 10 parts of SBR, 80 parts of tread reclaimed rubber, 5 parts of 60 mesh tread rubber powder on the double-roll mill for mixing, then add 1.9 parts of zinc oxide, 0.9 parts of stearic acid, RD 0.3 Parts, 4010NA 0.3 parts, N330 6.3 parts, naphthenic oil 0.9 parts, CZ 0.54 parts, DM 0.36 parts, and finally 0.72 parts S is added. After that, the rubber compound is packaged 10 times, mixed e...

example 2

[0031] The difference between this example and example 1 is that the dosage of 60 mesh tread rubber powder is changed. The specific formula is: BR 10 parts, SBR 10 parts, tread reclaimed rubber 80 parts, 60 mesh tread rubber powder 10 parts, zinc oxide 1.9 Parts, 0.9 parts of stearic acid, 0.3 parts of RD, 0.3 parts of 4010NA, 6.3 parts of N330, 0.9 parts of naphthenic oil, 0.72 parts of S, 0.54 parts of CZ, 0.36 parts of DM.

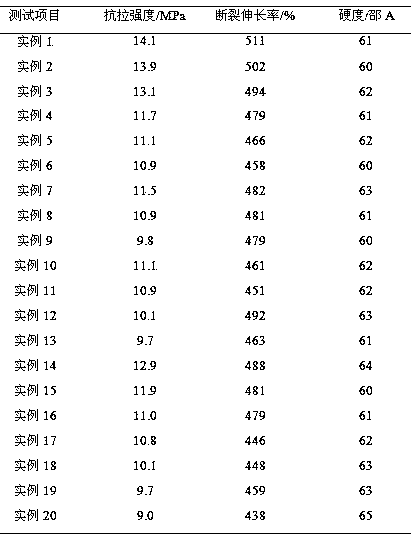

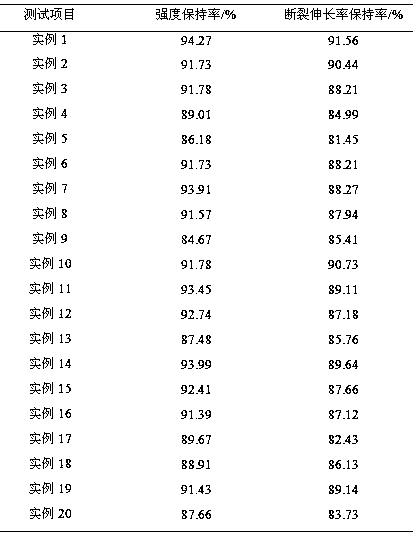

[0032] In this example, the BR / SBR / tread reclaimed rubber / rubber powder is used in combination with truck tire cushion belts. The test results of the vulcanized rubber are shown in Table 1 and Table 2.

example 3

[0034] The difference between this example and example 1 is that the dosage of 60 mesh tread rubber powder is changed. The specific formula is: BR 10 parts, SBR 10 parts, tread reclaimed rubber 80 parts, 60 mesh tread rubber powder 15 parts, zinc oxide 1.9 Parts, 0.9 parts of stearic acid, 0.3 parts of RD, 0.3 parts of 4010NA, 6.3 parts of N330, 0.9 parts of naphthenic oil, 0.72 parts of S, 0.54 parts of CZ, 0.36 parts of DM.

[0035] In this example, the BR / SBR / tread reclaimed rubber / rubber powder is used in combination with truck tire cushion belts. The test results of the vulcanized rubber are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com