Method for preparing hydrogen for fuel cell from yellow phosphorus tail gas

A yellow phosphorus tail gas, fuel cell technology, applied in the direction of fuel cells, separation methods, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

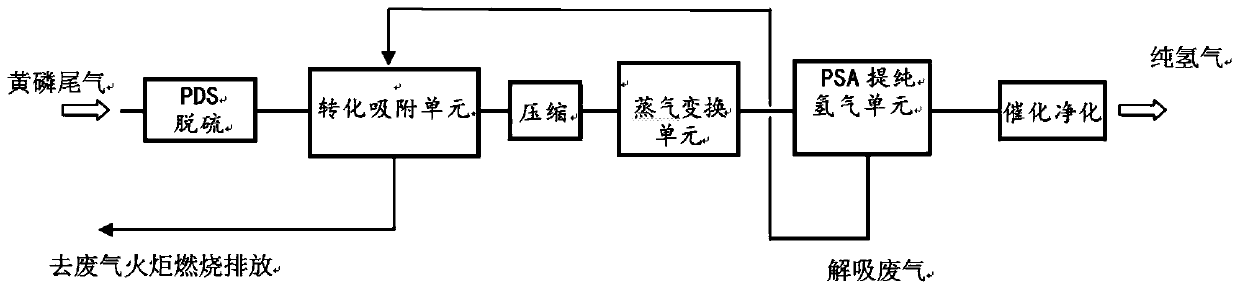

[0053] A method for producing hydrogen for fuel cells from yellow phosphorus tail gas. The yellow phosphorus tail gas passes through PDS unit, conversion adsorption unit, conversion unit, pressure swing adsorption decarburization unit, PSA / H2 pressure swing adsorption hydrogen purification unit and catalytic purification in sequence The unit is available.

[0054] The specific steps are as follows:

[0055] (1) Yellow phosphorus tail gas is used to remove hydrogen sulfide and some organic sulfides through the PDS unit;

[0056] Yellow phosphorus tail gas is yellow phosphorus tail gas emitted from low-quality fuel or vented flare combustion.

[0057] The PDS unit includes an absorption tower and an oxidation regeneration tower. The oxidation regeneration tower of the absorption tower is connected in series; the absorption liquid in the absorption tower is an aqueous solution using sodium carbonate as an alkali source and PDS catalyst and other additives are added. Bottom-up through th...

Embodiment 2

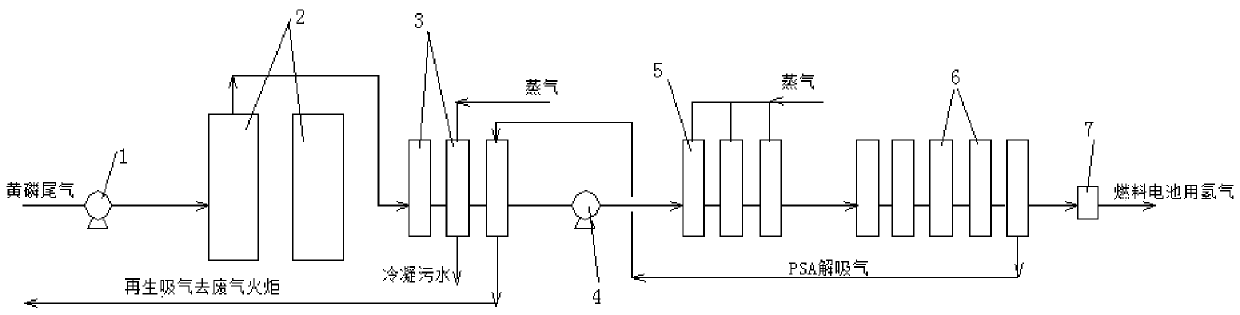

[0067] A method for preparing hydrogen for fuel cells from yellow phosphorus tail gas, in sequence, is as follows:

[0068] (1) Yellow phosphorus tail gas is used to remove hydrogen sulfide and some organic sulfides through the PDS unit;

[0069] Yellow phosphorus tail gas is yellow phosphorus tail gas emitted from low-quality fuel or vented flare combustion.

[0070] The PDS unit includes an absorption tower and an oxidation regeneration tower. The oxidation regeneration tower of the absorption tower is connected in series; the absorption liquid in the absorption tower is an aqueous solution using sodium carbonate as an alkali source and PDS catalyst and other additives are added. Bottom-up through the absorption tower filled with fillers, the absorption liquid containing PDS catalyst flows through the absorption tower from top to bottom; the absorption liquid after absorbing sulfide enters the oxidation regeneration tower, and air is blown into the absorption liquid through bubblin...

Embodiment 3

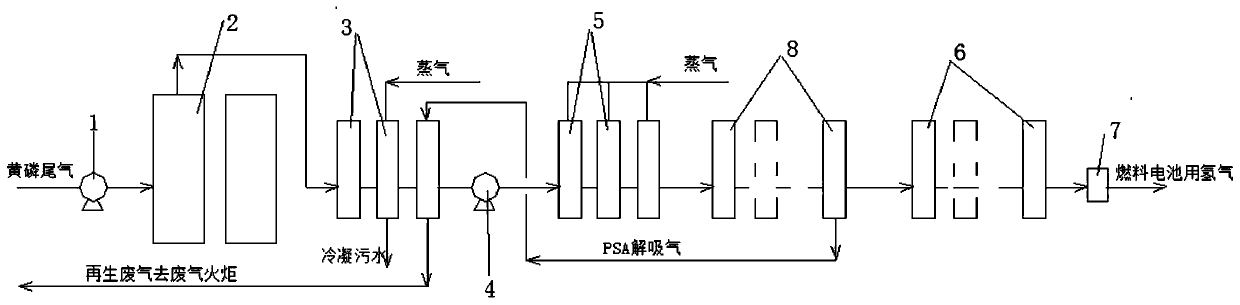

[0082] A method for preparing hydrogen for fuel cells from yellow phosphorus tail gas, which includes a PDS absorption and desulfurization unit, a conversion adsorption unit, a water vapor conversion unit, a pressure swing adsorption purification hydrogen unit and a catalytic purification unit in sequence.

[0083] The composition content of yellow phosphorus tail gas is as follows in Table 1: (where S, P, As, F are g / Nm 3 )

[0084] Table 1

[0085] ComponentH2

O2

N2

COCH 4

CO 2

ΣS ΣP ΣAs ΣFH 2 O

X Content V%10.00.804.0080.01.002.50300.080.020.12 saturation 100

[0086] Yellow phosphorus tail gas 3000Nm 3 / h, the pressure of 0.05Mpa enters the PDS desulfurization unit consisting of two absorption towers connected in series and one oxidation regeneration tower, and the hydrogen sulfide in the yellow phosphorus tail gas is removed to ~10ppm and then enters the conversion adsorption by three sets The conversion adsorption unit constituted by the reactor, where the PH in the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com