Carbon nitride-titanium nitride catalyst for synthesizing guaiacol, preparation method and application thereof

A titanium nitride catalyst, guaiacol technology, applied in physical/chemical process catalysts, chemical instruments and methods, dehydration of hydroxyl-containing compounds to prepare ether, etc., to delay carbon deposition, improve selectivity, and facilitate mass transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Zn modified porous carbon nitride-titanium nitride composite material, denoted as meso-ZnTiN / C, the preparation method is as follows:

[0039] (1) Prepare 600mL acetic acid aqueous solution (8wt%), add 60mL Ludox silicon oxide solution, 100g chitosan, 126g melamine, 340g n-butyl titanate and 30g zinc nitrate, fully stir at 30°C for 9h, and then add liquid at 100°C Evaporate to dryness to obtain block;

[0040] (2) The block was calcined at 800°C for 6h under a nitrogen atmosphere, the heating rate was 3°C / min, and then placed in an aqueous solution of ammonium bifluoride (5wt%) and stirred for 36h to remove the silica template, filtered, washed with distilled water, and dried at 120°C for 36h Then get meso-ZnTiN / C. The specific surface area of the catalyst is 456m 2 / g, pore diameter ~ 20nm, ICP measurement of Ti, Zn content of 23.6%, 4.3%.

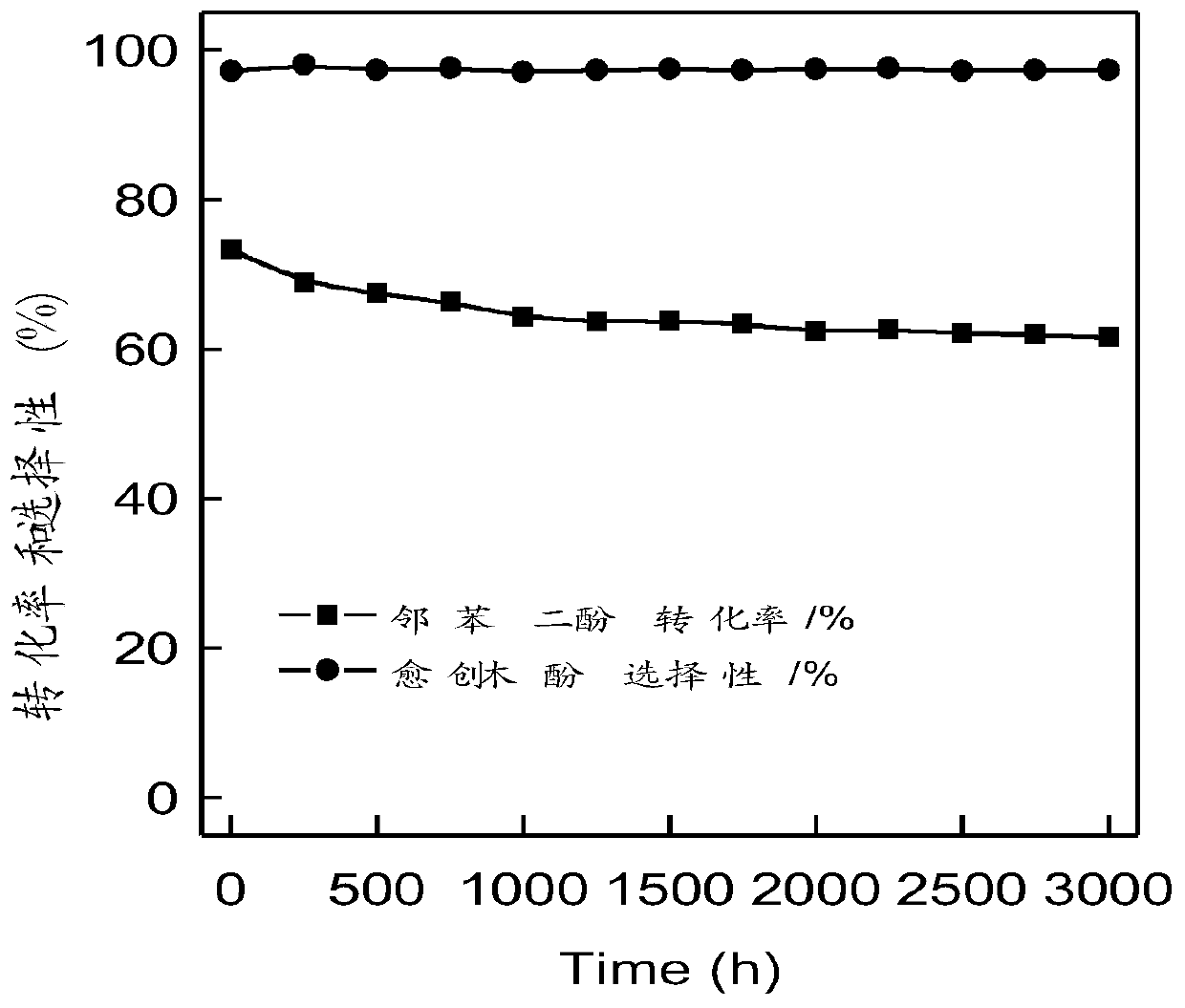

[0041] The meso-ZnTiN / C catalyst prepared above was used for gas-phase monoetherification of catechol and methanol to prepar...

Embodiment 2

[0043] The porous carbon nitride-titanium nitride composite material, denoted as meso-TiN / C, is prepared as follows:

[0044] (1) Prepare 400mL acetic acid aqueous solution (6wt%), add 40mL Ludox silica solution, 100g chitosan, 126g melamine and 272g n-butyl titanate, fully stir at 20°C for 12h, and evaporate to dryness at 80°C to obtain block shape;

[0045] (2) The block was calcined at 500°C for 8h under a nitrogen atmosphere, the heating rate was 1°C / min, and then placed in an aqueous solution of ammonium bifluoride (2wt%) and stirred for 60h to remove the silica template, filtered, washed with distilled water, and dried at 100°C for 60h Then get meso-TiN / C. The specific surface area of the catalyst is 417m 2 / g, the pore diameter is ~16nm, and the Ti content is 26.8% as determined by ICP.

[0046] The meso-TiN / C catalyst prepared above was used for gas-phase monoetherification of catechol and methanol to prepare guaiacol. The specific steps are as follows: after loa...

Embodiment 3

[0048] Ce-modified porous carbon nitride-titanium nitride composite material, denoted as meso-CeTiN / C, is prepared as follows:

[0049] (1) Prepare 800mL acetic acid aqueous solution (10wt%), add 80mL Ludox silicon oxide solution, 100g chitosan, 126g melamine, 408g n-butyl titanate and 87g cerium nitrate, fully stir at 40°C for 6h, and add liquid at 120°C Evaporate to dryness to obtain block;

[0050] (2) The block was calcined at 1200°C for 4h under a nitrogen atmosphere, the heating rate was 6°C / min, and then placed in an aqueous solution of ammonium bifluoride (10wt%) and stirred for 12h to remove the silica template, filtered, washed with distilled water, and dried at 150°C for 12h Then get meso-CeTiN / C. The specific surface area of the catalyst is 358m 2 / g, pore diameter ~ 12nm, ICP measurement Ti, Ce content is 28.2%, 6.5%.

[0051] The meso-CeTiN / C catalyst prepared above was used for gas-phase monoetherification of catechol and methanol to prepare guaiacol. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com