A method for preparing heavy metal adsorbent by using waste polyvinyl chloride plastic

A technology of waste polyvinyl chloride and polyvinyl chloride, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of poor recycling of waste polyvinyl chloride plastics, etc., and achieve increased recycling Effect of utilization, increase of specific surface area, effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

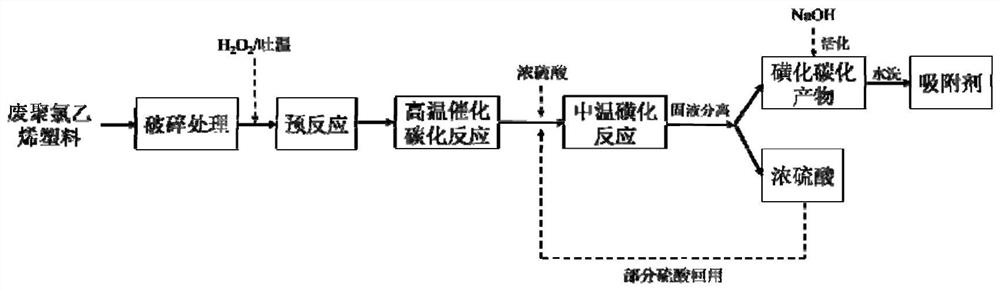

Method used

Image

Examples

Embodiment 1

[0028] A kind of method utilizing waste polyvinyl chloride plastics to prepare heavy metal adsorbent:

[0029] (1) Take waste and old polyvinyl chloride plastics (waste plastic pipes, waste plastic bottles, etc.) and crush them to 60 mesh through a crusher. Weigh 12g of broken plastic and place it in a high-temperature reactor, and add 32% H 2 o 2 Mix 50mL with liquid Tween, the mass ratio is 1:0.1; Stir at 35°C at a speed of 80r / min for a pre-reaction for 20min. After the crushed plastic and the catalyst are fully mixed, close the reactor. Set the temperature of the oven at 220°C to continue the catalytic reaction for 5 hours. After the reaction time is up, take the high-temperature reactor out of the oven and cool it down to room temperature naturally;

[0030] (2) performing solid-liquid separation on the mixture in the reactor to obtain a hydrothermal carbonization product. Weigh 5 g of the hydrothermal carbonization product into the reactor, and add 40 mL of 98% concen...

Embodiment 2

[0033] A kind of method utilizing waste polyvinyl chloride plastics to prepare heavy metal adsorbent:

[0034] (1) Take waste and old polyvinyl chloride plastics (waste plastic pipes, waste plastic bottles, etc.) and crush them to 100 mesh through a crusher. Weigh 15g of broken plastic and place it in a high-temperature reaction kettle, and add 32% H 2 o 2 Mix 45mL with Tween in a liquid state, the mass ratio is 1:0.25; Stir at a temperature of 35°C at a speed of 110r / min for a pre-reaction for 15min. After the crushed plastic and the catalyst are fully mixed, close the reactor. Set the temperature of the oven at 210°C to continue the catalytic reaction for 6 hours. After the reaction time is up, take the high-temperature reactor out of the oven and cool it down to room temperature naturally;

[0035] (2) performing solid-liquid separation on the mixture in the reactor to obtain a hydrothermal carbonization product. Weigh 8 g of hydrothermal carbonization product into the r...

Embodiment 3

[0038] A kind of method utilizing waste polyvinyl chloride plastics to prepare heavy metal adsorbent:

[0039] (1) Take waste and old polyvinyl chloride plastics (waste plastic pipes, waste plastic bottles, etc.) and crush them to 80 meshes through a crusher. Weigh 10 g of broken plastic and place it in a high-temperature reaction kettle, and add 32% H 2 o 2Mix 45mL with Tween in a liquid state, the mass ratio is 1:0.15; Stir at a temperature of 40°C at a speed of 65r / min for a pre-reaction for 10min. After the crushed plastic and the catalyst are fully mixed, close the reactor. Set the temperature of the oven at 240°C to continue the catalytic reaction for 3 hours. After the reaction time is up, take the high-temperature reactor out of the oven and cool it down to room temperature naturally;

[0040] (2) performing solid-liquid separation on the mixture in the reactor to obtain a hydrothermal carbonization product. Weigh 5 g of the hydrothermal carbonization product into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com