CT image based porous implant making method and system

A technology of CT images and production methods, which is applied in the fields of dental implants, medical science, and dental restorations. It can solve problems such as implant failure, implant loosening, and unfavorable new bone growth, and achieve a high degree of fit, lower elastic modulus, and The effect of avoiding the stress shielding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

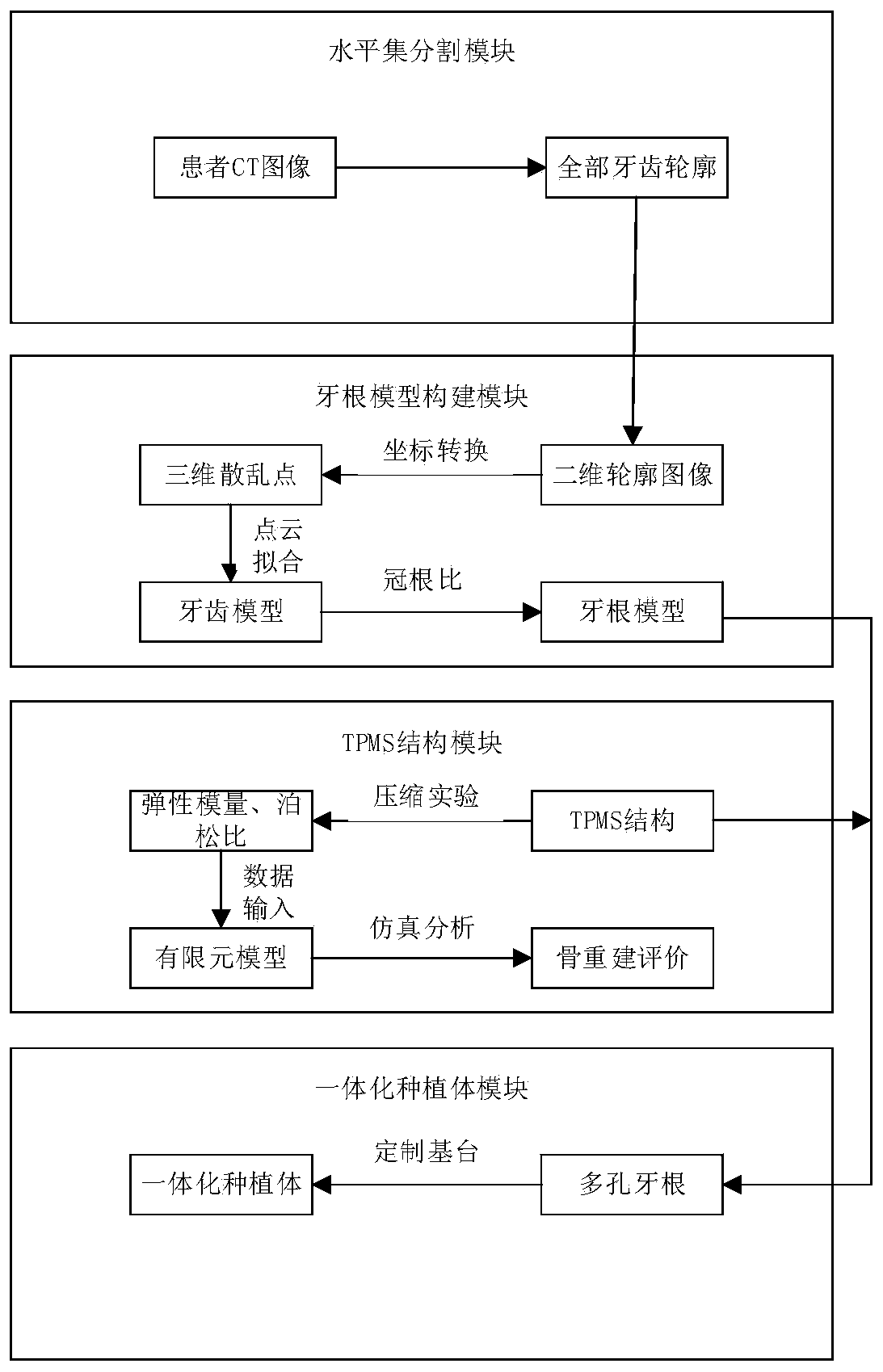

[0031] This embodiment provides a method for making porous implants based on CT images, such as figure 1 As shown, firstly, all contours of a single tooth are segmented according to the patient’s oral CT image, and then the segmented contour is converted into a 3D point cloud format by using the coordinate transformation mechanism, and the whole tooth model is reconstructed; The root part of the tooth model is obtained by segmenting the tooth model. According to the patient's root part and crown part (if the crown part does not exist, the mirror image crown is considered), the personalized abutment is reconstructed, and the three-period minimal surface (Triply Periodic Minimal Surfaces, TPMS) structure is used to reconstruct the shape of the root. A customized root-type implant integrated with the porous structure abutment implant.

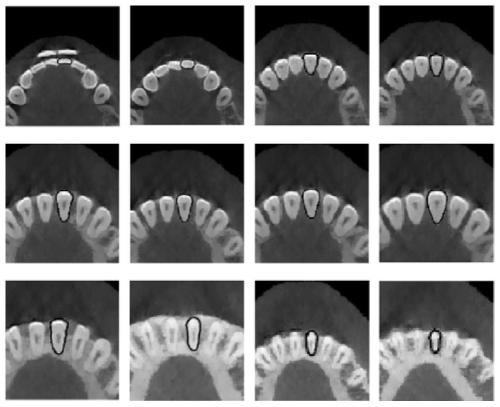

[0032] Because oral CT images have the characteristics of uneven gray scale, the mixed level set model can accurately identify the contour of a ...

Embodiment 2

[0054] This embodiment provides a CT image-based porous implant production system, including:

[0055] Contour segmentation module: used to segment the contour of a single tooth according to the patient's oral CT image;

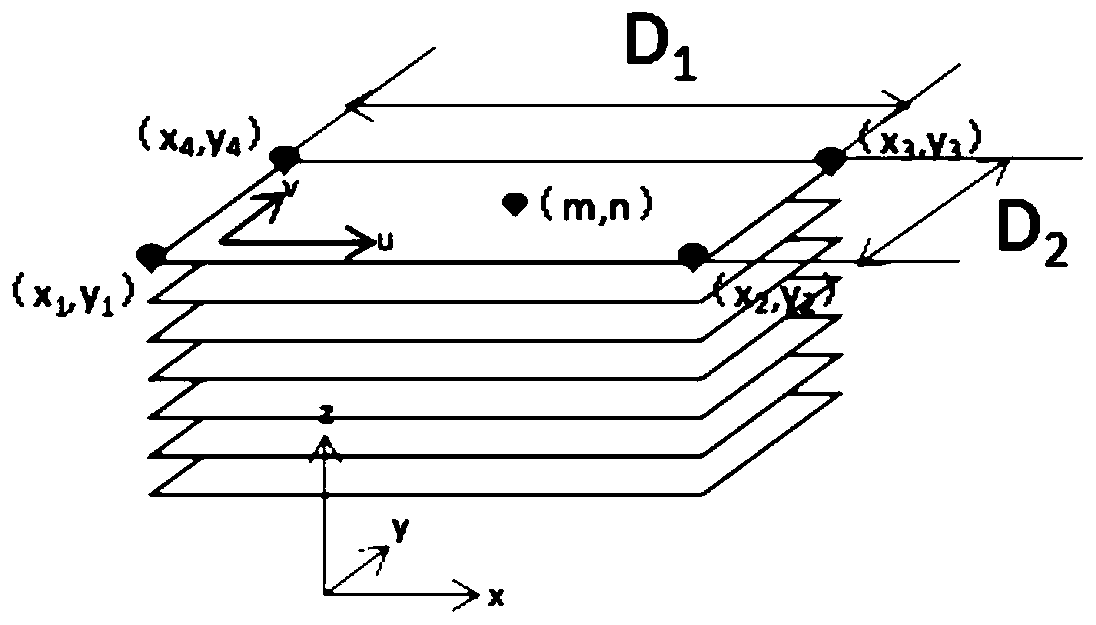

[0056] Root model reconstruction module: used to convert the segmented tooth contour into a three-dimensional point cloud format, and reconstruct the tooth model; and determine the crown-to-root ratio according to the CT image to segment to obtain the tooth root model;

[0057] Porous structure design module: used to design the shape of the porous structure implant according to the shape of the patient's tooth root;

[0058] Implant model building module: It is used to design a personalized abutment according to the root part and the crown part or the mirror image crown part, and finally establish a root-shaped implant with the abutment implant integrated.

Embodiment 3

[0060] The purpose of this embodiment is to provide an electronic device, including a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the program, the following steps are implemented, including:

[0061] Segment the outline of a single tooth based on the patient's oral CT image;

[0062] Convert the segmented tooth outline into a 3D point cloud format to reconstruct the tooth model; and determine the crown-to-root ratio according to the CT image to segment to obtain the tooth root model;

[0063] Design the shape of the porous structure implant according to the shape of the patient's tooth root;

[0064] Design a personalized abutment according to the root part and the crown part or the mirror image crown part, and finally establish a root-shaped implant with an integrated abutment-implant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com