Jet pump-double-screw pump same-well injection-production composite lifting system and method

A technology of injection and production in the same well, twin-screw pump, applied in the directions of pumps, pump devices, and production fluids, etc., can solve the problems of increasing the complexity of surface devices, lag in valve ball opening and closing, and can not be too large, so as to reduce output. The effect of water volume, increasing lifting depth, and reducing lifting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

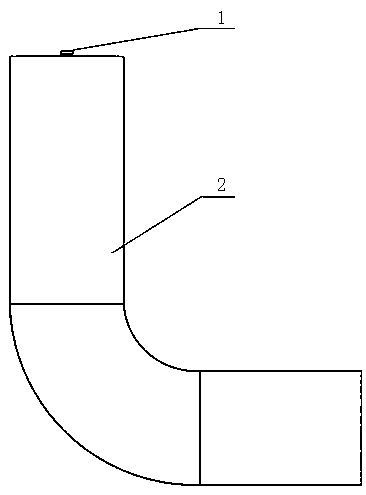

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] to combine figure 1 , figure 2 As shown, this jet pump-twin-screw pump same-well injection-production composite lifting system includes a production system, a downhole oil-water separation system and an injection system; In the jet pump 24, the separated oil is extracted to the ground, and the separated water is injected into the jet pump 24 after the pressure is provided by the screw pump. Oil-water separation is carried out in the separation system, and the separated liquid with more oil content is lifted to the ground by the screw pump, and the two-stage lifting takes over to realize production.

[0027] The extraction system includes the upper interface 1 connected to the top of the casing 2 through threads, the upper interface 1 is welded to the upper screw pump 3, the lower part of the upper screw pump 3 is connected to the upper coupling 5, and the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com