Comprehensive capillary permeation type yarn waxing process

A capillary penetration and yarn technology, applied in the field of comprehensive capillary penetration yarn waxing process, to avoid poor waxing uniformity, reduce friction, and improve hand feel and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

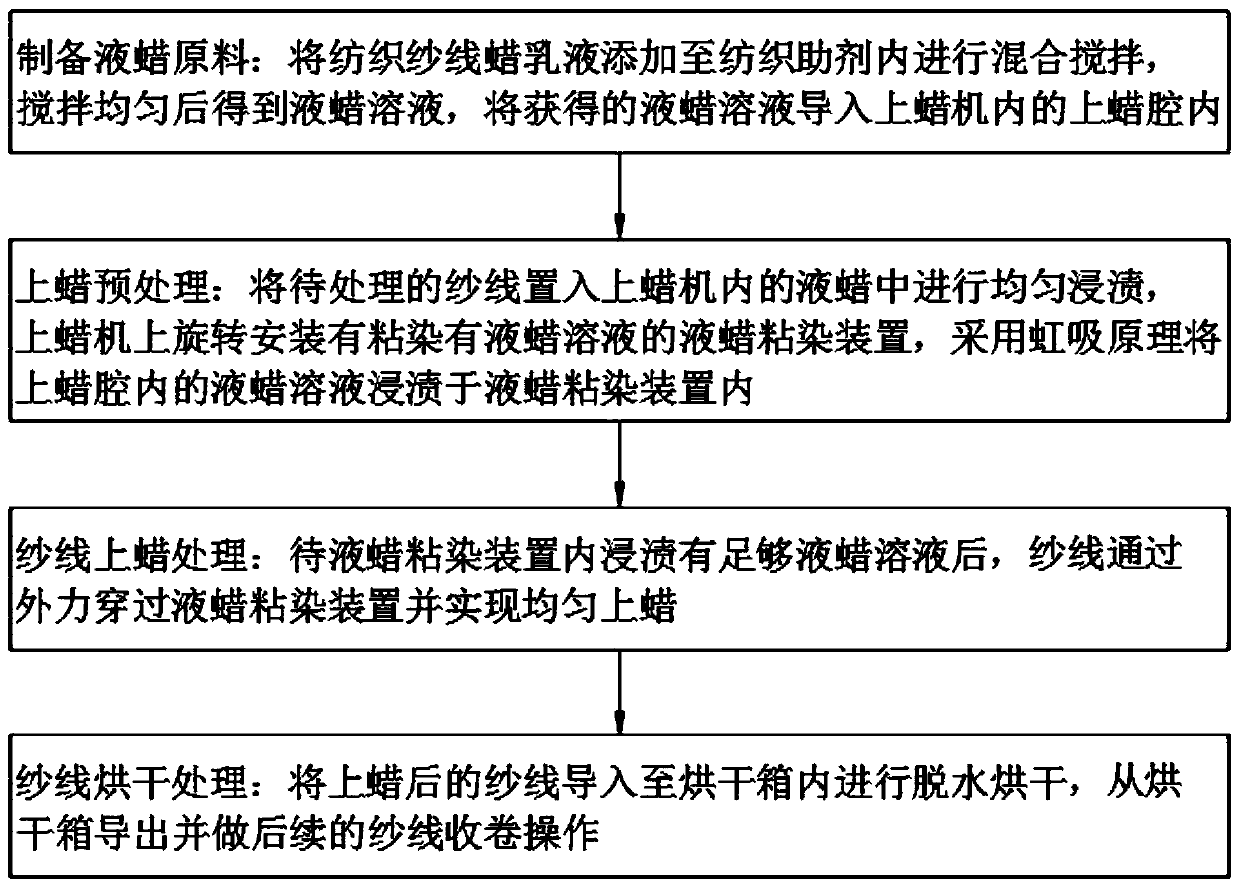

[0038] See figure 1 , A comprehensive capillary penetration yarn waxing process, including the following steps:

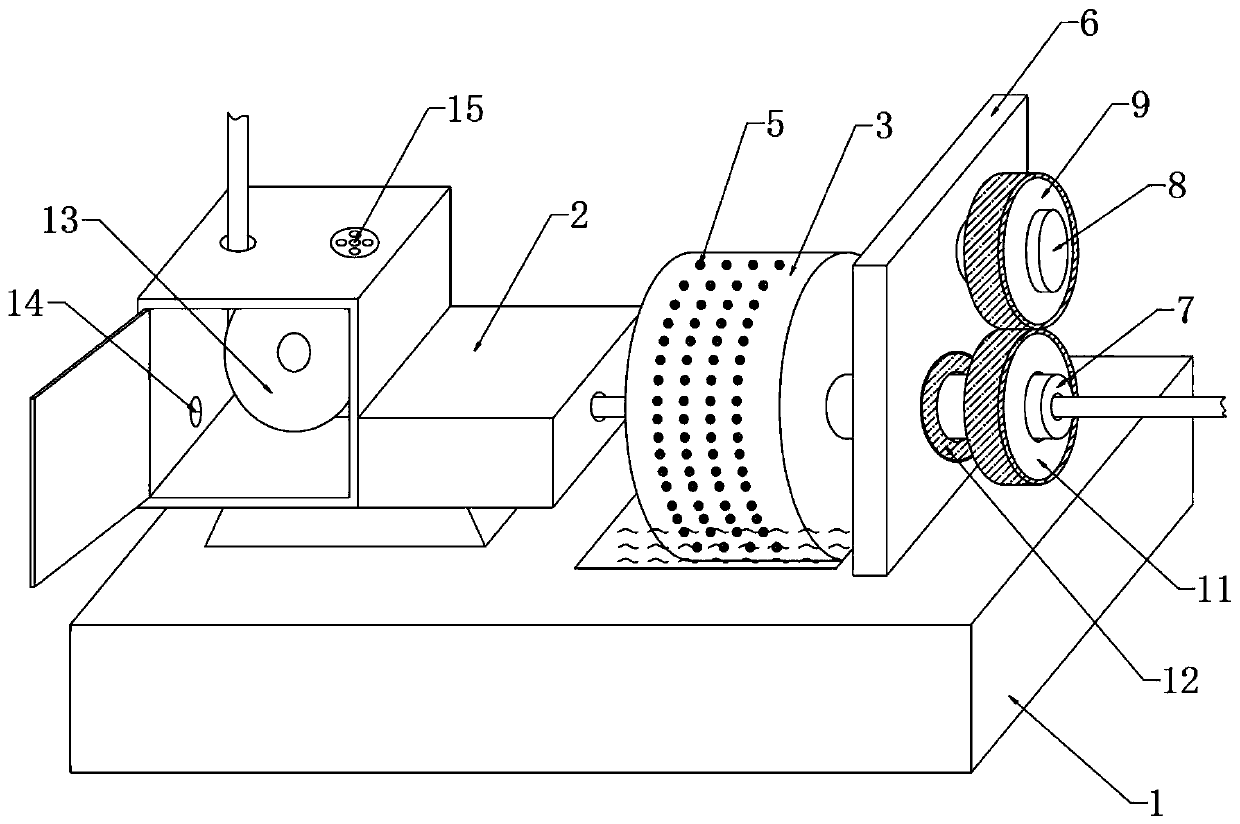

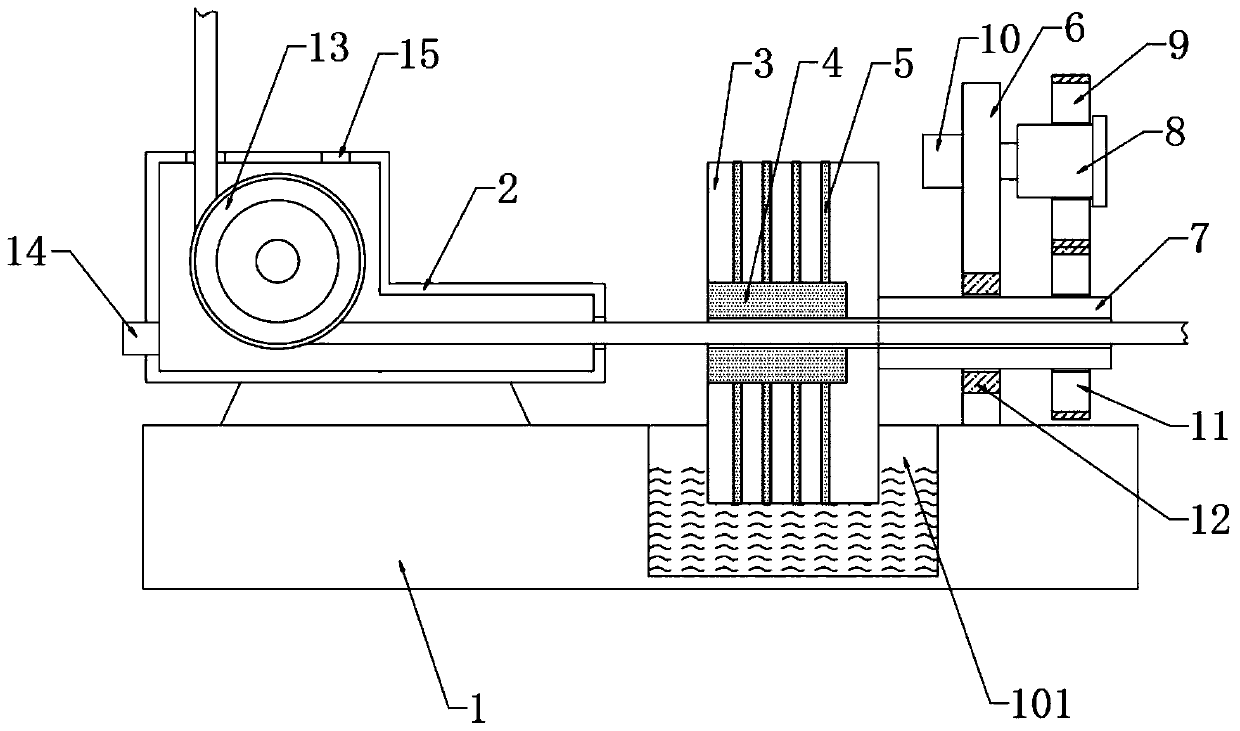

[0039] S1. Preparation of liquid wax raw materials: add the textile yarn wax emulsion to the textile auxiliaries for mixing and stirring, adjust the pH to 5-6.5, and stir evenly to obtain a liquid wax solution, and introduce the obtained liquid wax solution into the waxing machine 1 In the waxing chamber 101;

[0040] S2. Waxing pretreatment: Put the yarn to be processed into the liquid wax in the waxing machine 1 for uniform dipping. The waxing machine is rotated and installed with a liquid wax bonding device that is stained with a liquid wax solution. The bottom of the dyeing device is placed in the waxing chamber 101, and the liquid wax solution in the waxing chamber 101 is immersed in the liquid wax sticking device by the capillary penetration principle.

[0041] S3. Yarn waxing treatment: After enough liquid wax solution is immersed in the liquid wax dyeing device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com