Preparation process of semi-mortise and tenon joint structure at wooden product joint

A preparation process and joint technology, which is applied in the field of preparation technology of semi-tenon-mortise structure at the joint of wood products, can solve the problems of loose joints on the side of the picture frame, affecting the service life of the picture frame, and the degree of connection is not tight enough, so as to improve the smoothness of the picture frame. degree, improve the service life, not easy to loosen the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

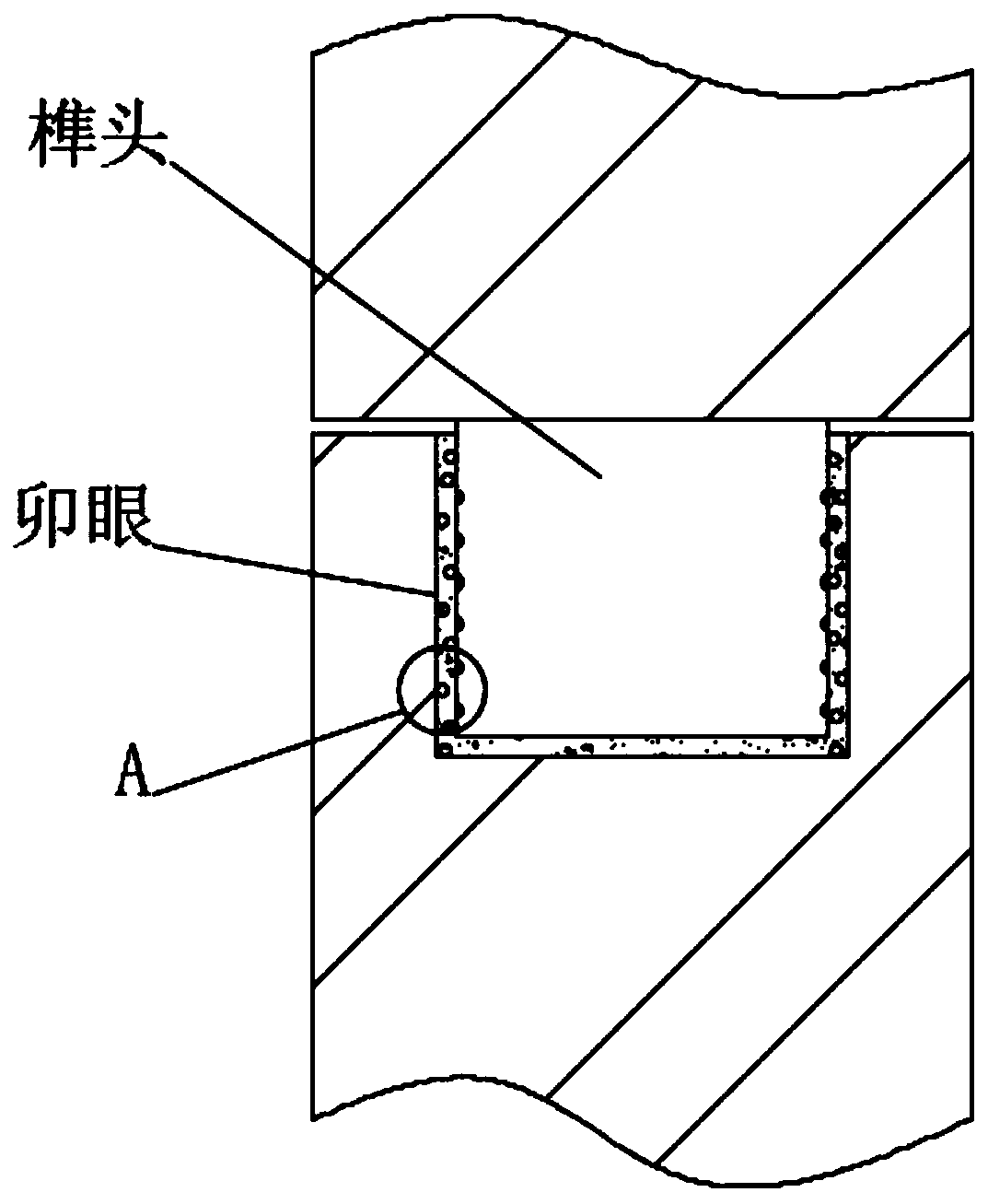

[0052] see figure 1 , a half-mortise and tenon joint structure preparation process of wood products, comprising the following steps:

[0053] S1. First determine the position where the tenon and tenon joints need to be set at the connection of wood products;

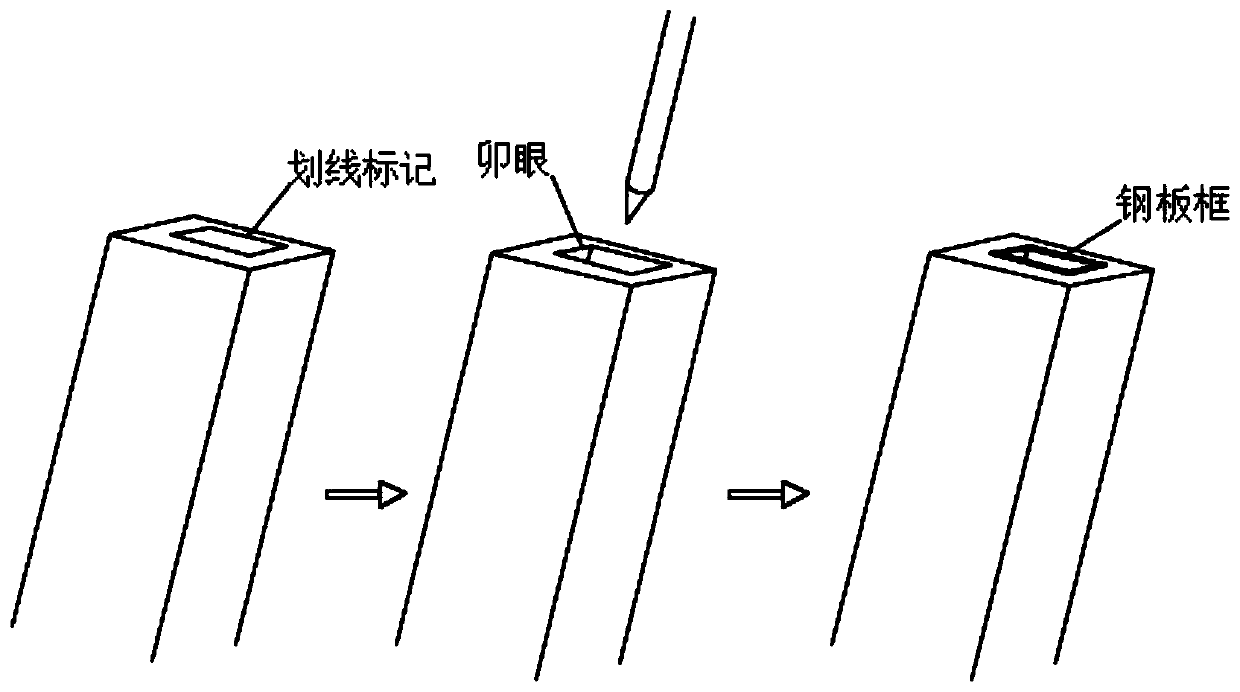

[0054] S2. Scribing and positioning, determining the size of the mortise and tenon, marking the wood products determined in S1, and locating the length, width and depth of the mortise;

[0055] S3. Drilling and digging the mortise hole according to the above marks on the CNC machine tool to obtain a rough mortise hole on the inner wall, and cutting through the CNC machine tool to obtain the mortise head;

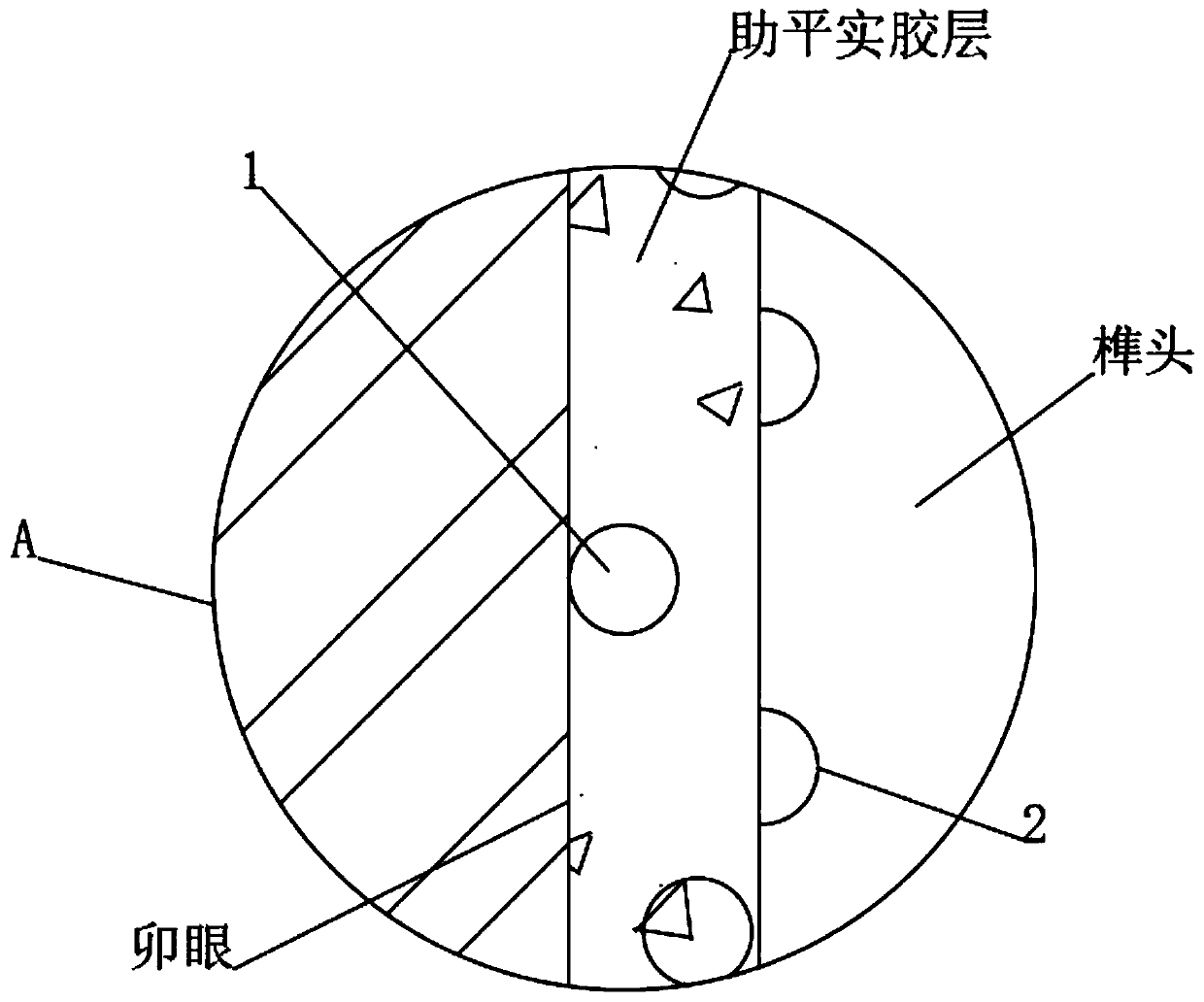

[0056] S4. Grinding the side wall of the mortise, after grinding, and then performing plate ball milling on the inner wall of the mortise mouth by directly facing the ball milling plate;

[0057] S5. After the plate ball mill is finished, remove the grinding debris in the mortise, insert a steel plate frame that matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com