Cement mortar paver and its elastic membrane paving mechanism and paving control method

A technology of cement mortar and paver, applied in the direction of building construction, construction, etc., can solve the problems of low efficiency, uneven cement surface, etc., and achieve the effect of high work efficiency, large bottom area, and improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

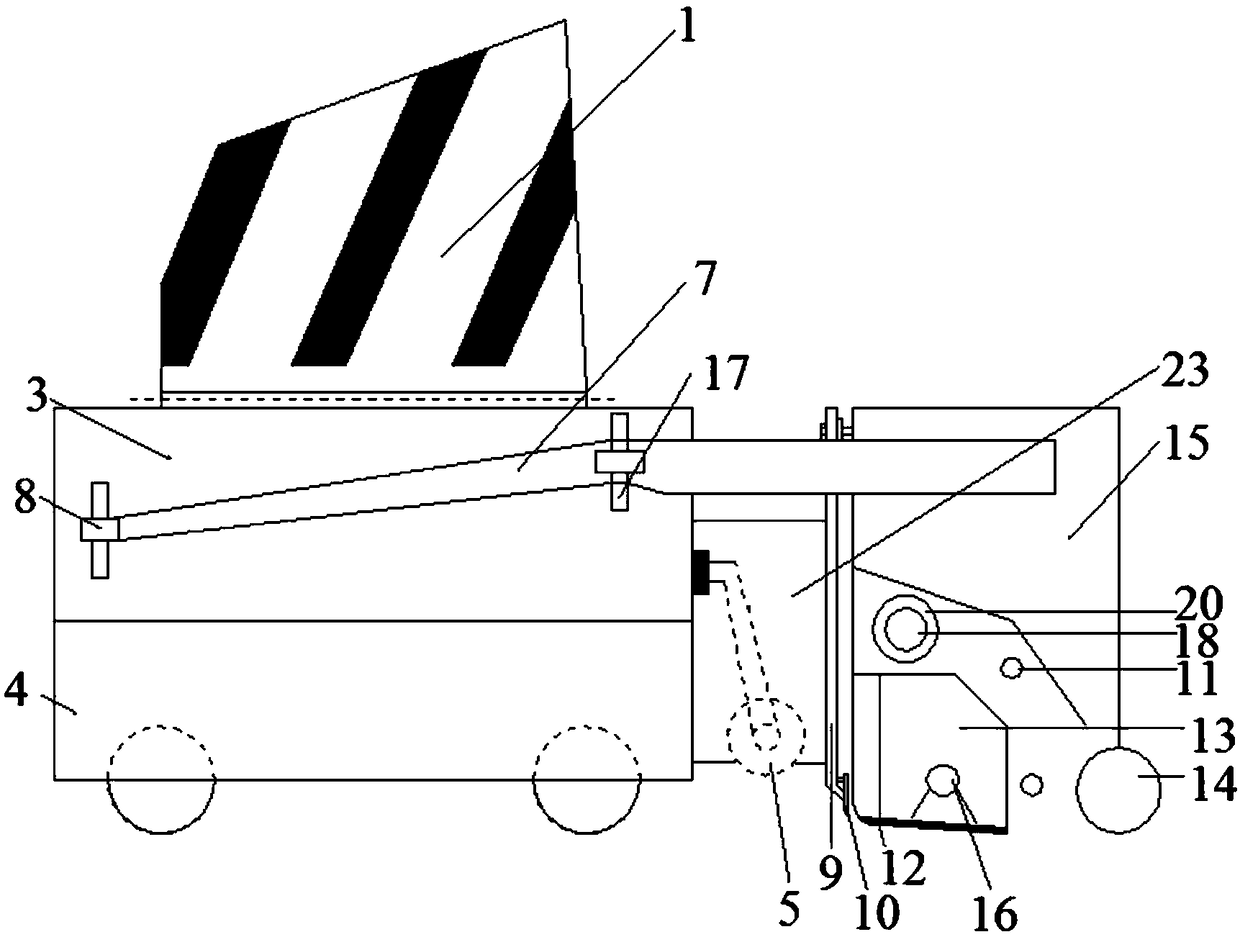

[0086] Such as figure 1 Shown, a kind of cement mortar paver, it comprises feeding hopper 1, smart trolley 4, conveying scraper device 3, hopper 23, screw distributor 5 and screed system. The smart car 4 is used as the basic device for the whole movement. The bottom of the smart car 4 is provided with casters, and the rotation speed of the casters is controlled by a servo motor. The feeding hopper 1 is connected to the top of the conveying scraper 3 as the feeding port of the whole system, which is convenient for the mortar to enter the paver.

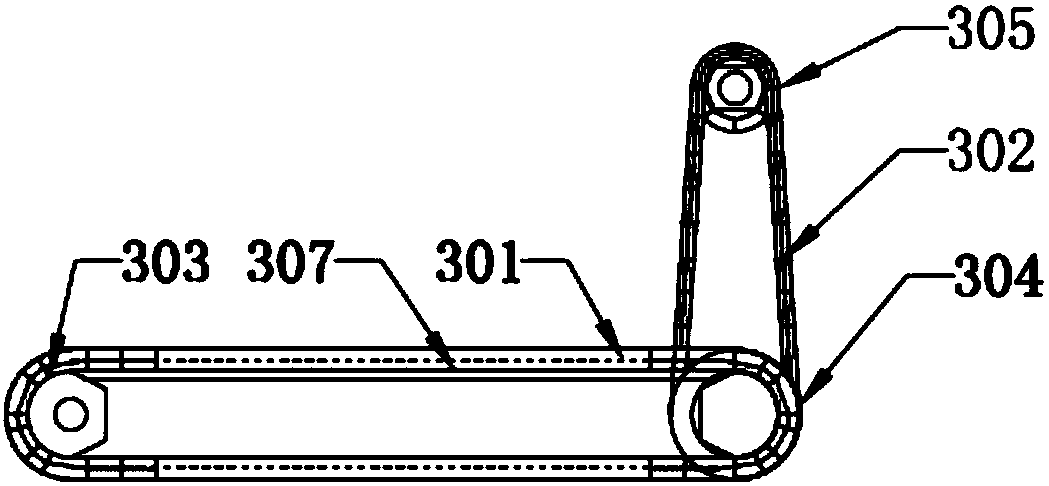

[0087] Such as image 3 with Figure 4 As shown, the conveying scraper 3 includes a scraper chain 301, a drive chain 302, a guide wheel 303, a drive wheel 304, a scraper 306, a channel bottom plate 307, a driving device 305 and a supporting frame, and the scraper chain 301 is connected with a guide wheel 303 and drive wheel 304 are fixed fulcrums to form a closed rotary chain. There are two rotary chains, and the two rotary chains a...

Embodiment 2

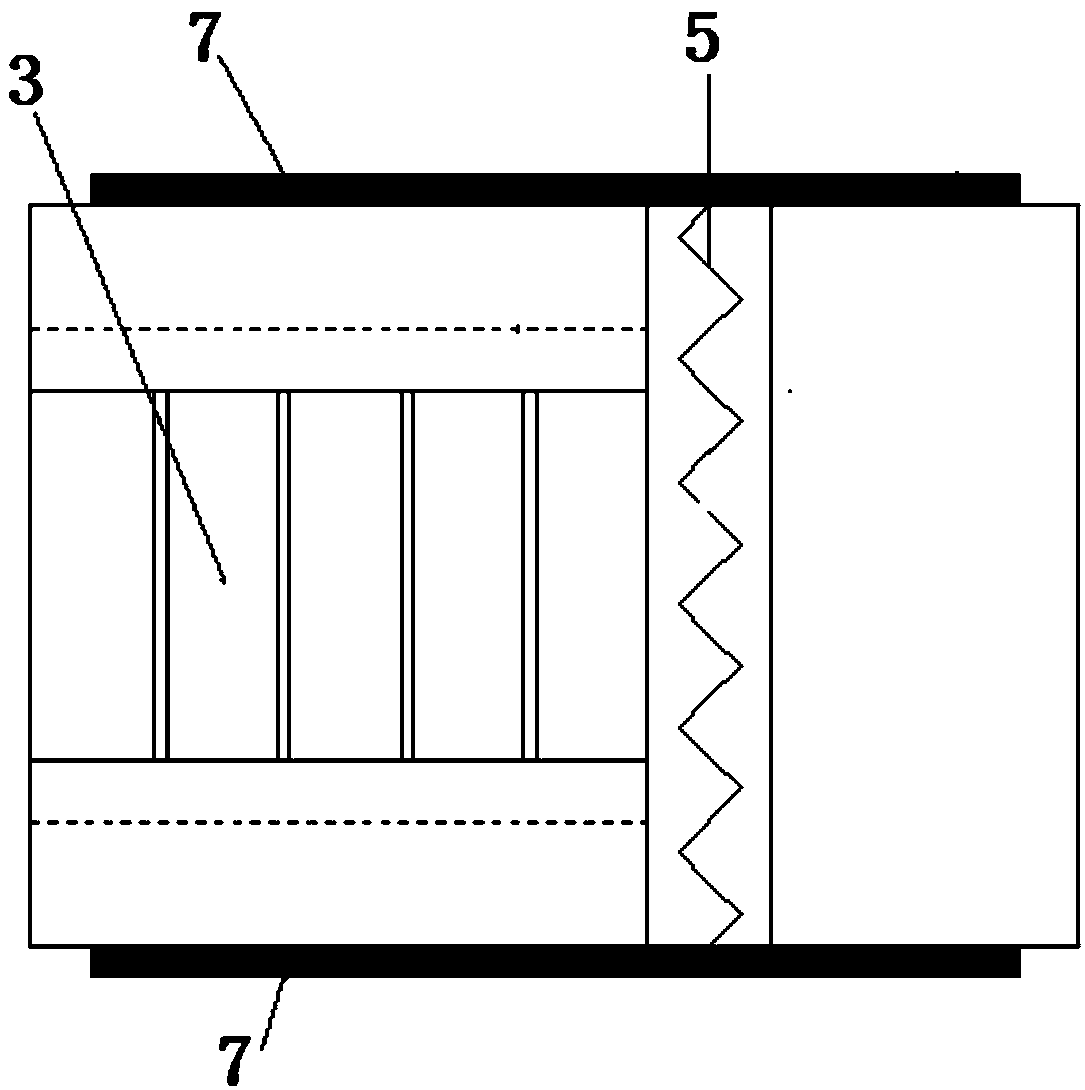

[0094] A kind of cement mortar paver of the present embodiment is similar to embodiment 1, the difference is that, as figure 1 with figure 2 As shown, the ironing system is connected with the conveying scraper 3 through the arm plate 7, and the arm plate 7 is fixed on the ironing system, and the arm plate 7 and the side of the conveying scraper 3 pass through the guide rail slider The first 8 is connected with the guide rail slider 2 17, the guide rail slider 1 8 and the guide rail slider 2 17 have the same structure and both include guide rails and sliders, the guide rails are fixed on the side of the conveying scraper 3, and the sliders are fixed on the force arm on board 7.

[0095] In order to adjust the vertical height of the screed system, the conveying scraper 3 and the screed system are flexibly connected through the force arm plate 7, and the following three connection methods can be adopted: the first one is that the force arm plate 7 is fixed On the board device ...

Embodiment 3

[0098] A kind of cement mortar paver of the present embodiment is similar to embodiment 2, the difference is that, as figure 1 As shown, the screed system includes a tailgate 9 , a scraper 10 , a screed soleplate 12 and a screed side plate 13 . The rear baffle 9 and the screed side plate 13 are used as the supporting base of the screed system, and the back baffle 9 and the screed side plate 13 are all fixed on the force arm plate 7 . The scraper 10 is used to initially scrape the mortar, and the scraper 10 is fixed on the bottom of the tailgate 9 , and the scraper 10 is located between the screw distributor 5 and the screed base 12 . Such as Image 6 Shown, in order to increase the scraping efficiency of scraper 10, have otch on the bottom surface of scraper 10, otch is towards screw distributor 5, and the angle a of otch is 15 ° (can also get 14 °, 14.5 ° and 16° etc.), when scraping, excess mortar can be discharged in time along the cutting surface of the scraper 10, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com