A hot press for mold steel

A technology of heat press and die steel, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low correction efficiency and high labor cost, and achieve the effect of reducing processing cost, high processing efficiency, and not easy to rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

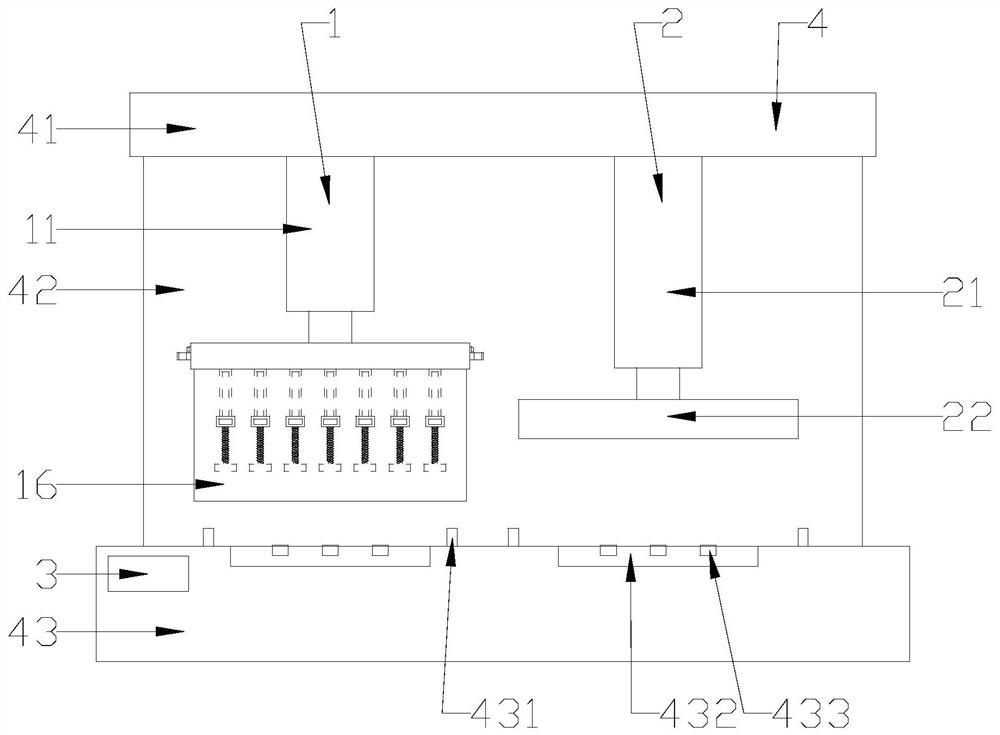

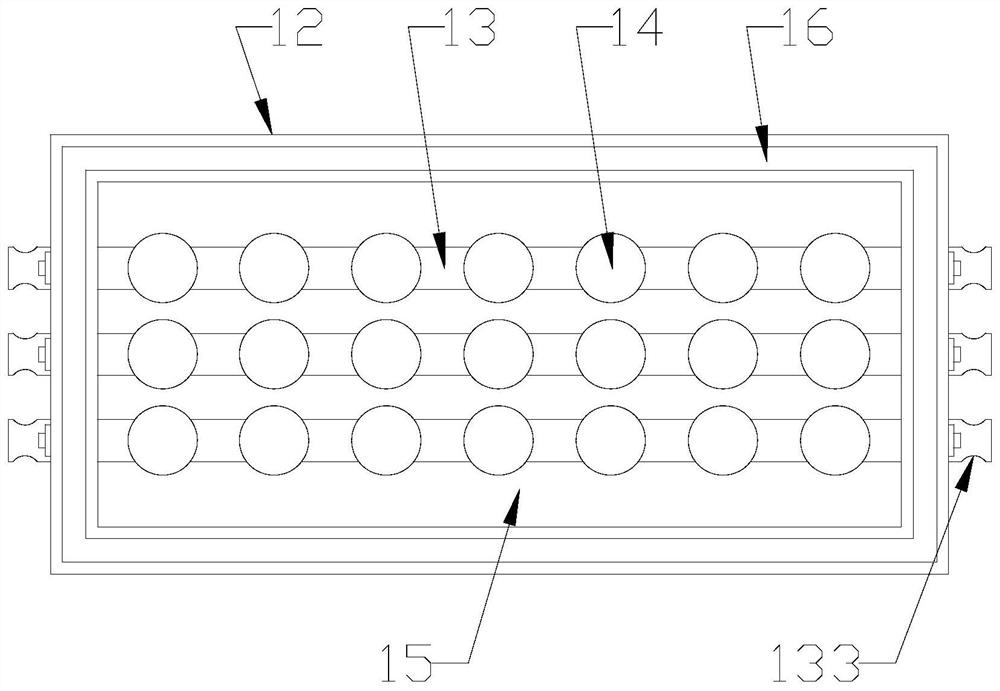

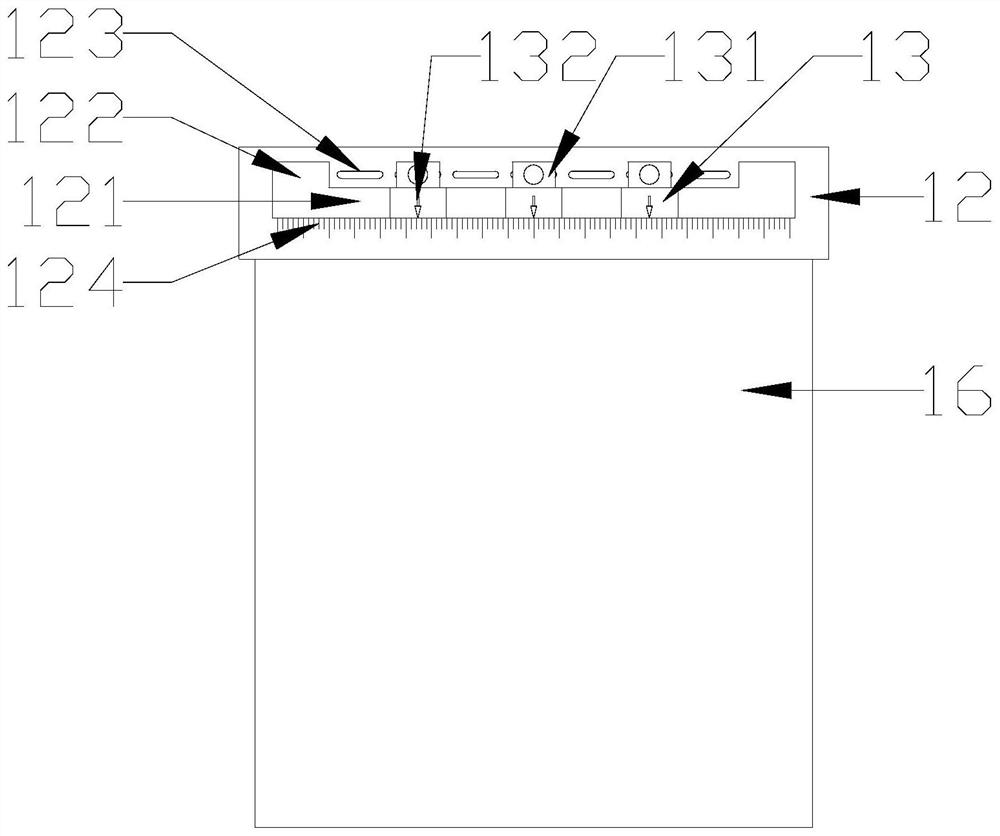

[0019] refer to Figure 1 to Figure 4 , a hot press for mold steel in the present invention, comprising a stamping table 4, a heater 1 and a punch 2 respectively fixed on the left and right sides of the top of the stamping table 4, and a controller electrically connected to the heater 1 and the punch 2 respectively 3. The heater 1 includes a first cylinder 11, an end plate 15 fixed at the end of the telescopic rod of the first cylinder 11, a support frame 12 fixed on the bottom of the end plate 15, and several slide plates fixed in the support frame 12 in sequence 13 and several heating heads 14 sequentially fixed on the bottom surface of the slide plate 13, the stamper 2 includes a second cylinder 21 and a stamping head 22 fixed at the end of the telescopic rod of the second cylinder 21, the left and right sides of the support frame 12 There are through grooves 121 respectively, and the two ends of the through grooves 121 are respectively provided with upwardly extending end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com