A kind of electrolytic water catalyst supporting transition metal single atom and preparation method thereof

A transition metal, water electrolysis technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the complicated preparation method, unfavorable mass production, limited application, etc problem, to achieve the effect of improved catalytic activity, good chemical stability and durability, high specific surface area and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

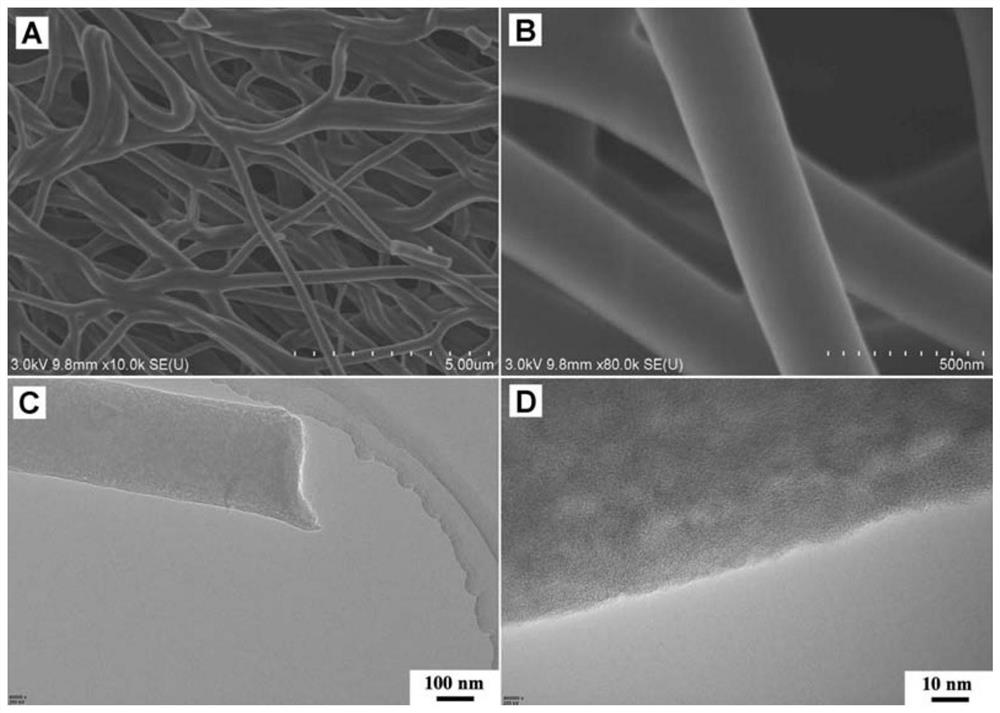

[0030] (1) Mix 57 mg of iron phthalocyanine, 103 mg of phthalocyanine, and 7 mL of dimethylformamide, and stir at 30° C. for 0.5 h to obtain a uniform solution. Add 0.9 g of polyacrylonitrile to the above solution (the mass concentration of polyacrylonitrile is 12%), stir the mixture at 30°C for 5 hours to obtain an electrospinning solution, and then prepare the electrospinning solution into a phthalocyanine complex Material-coupled fiber mat, the spinning voltage is controlled at 5kV during electrospinning, the distance from the receiving device to the spinning needle is 4cm, and the solution flow rate is 0.01mL / min;

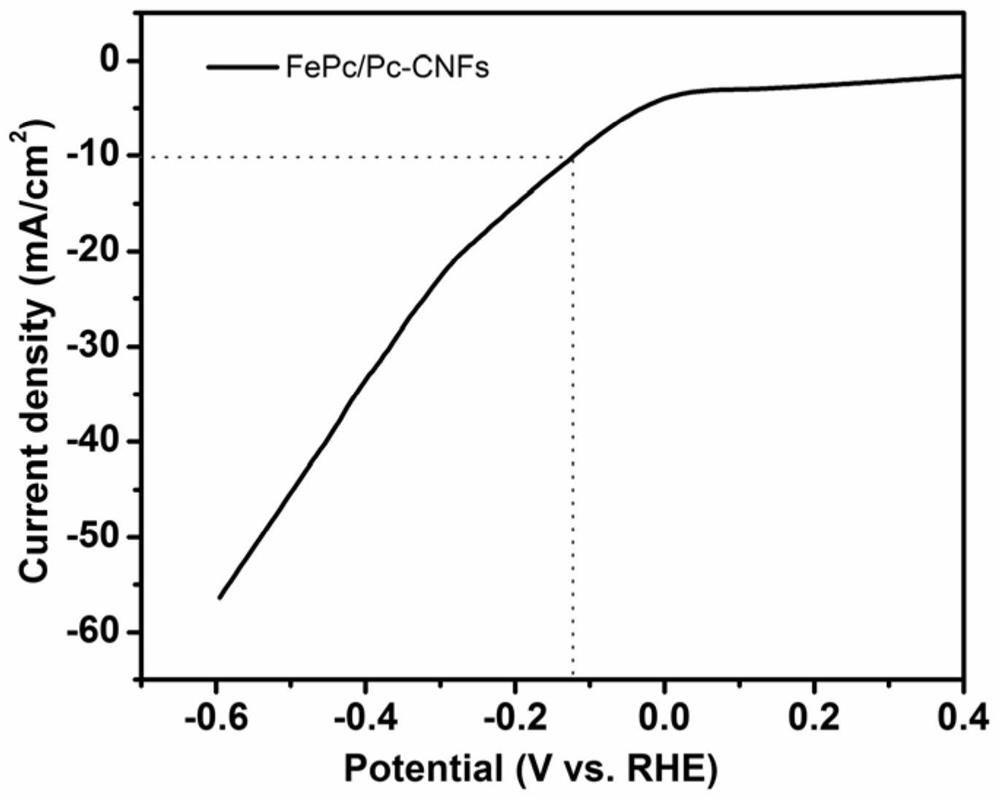

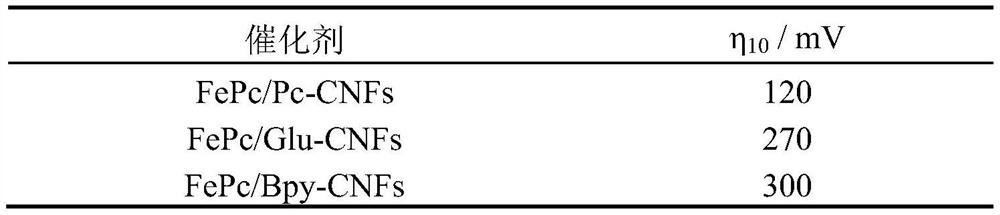

[0031] (2) Place the fiber mat coupled with phthalocyanine complexes in a corundum boat, place the corundum boat in the middle of the tube furnace, and pre-oxidize with air. , heated to 850°C, kept for 4h, and finally cooled to room temperature under the protection of inert gas to obtain the fiber-supported ferroelectric catalyst, which was named FePc / Pc-CNFs. ...

Embodiment 2

[0039] (1) Mix 57mg iron phthalocyanine, 103mg phthalocyanine, and 7mL DMF solution, and stir at 30°C for 0.5h to obtain a uniform solution. Add 0.9 g of polyacrylonitrile to the above solution (the mass concentration of polyacrylonitrile is 12%), stir the mixture at 30°C for 5 hours to obtain an electrospinning solution, and then prepare the electrospinning solution into a phthalocyanine complex Material-coupled fiber mat, the spinning voltage is controlled at 5kV during electrospinning, the distance from the receiving device to the spinning needle is 4cm, and the solution flow rate is 0.01mL / min;

[0040] (2) Place the fiber mat coupled with phthalocyanine complexes in a corundum boat, place the corundum boat in the middle of the tube furnace, and pre-oxidize with air. , heated to 750°C or 950°C, kept for 4h, and finally cooled to room temperature under the protection of inert gas, and two fiber-supported ferroelectric catalysts were obtained, named FePc / Pc-CNFs-750 and FePc...

Embodiment 3

[0045] (1) Mix 57mg iron phthalocyanine and 7mL DMF solution, stir at 30°C for 0.5h to obtain a uniform solution. Add 0.9 g of polyacrylonitrile to the above solution (the mass concentration of polyacrylonitrile is 12%), stir the mixture at 30°C for 5 hours to obtain an electrospinning solution, and then prepare the electrospinning solution into a phthalocyanine complex Material-coupled fiber mat, the spinning voltage is controlled at 5kV during electrospinning, the distance from the receiving device to the spinning needle is 4cm, and the solution flow rate is 0.01mL / min;

[0046] (2) Place the fiber mat coupled with phthalocyanine complexes in a corundum boat, place the corundum boat in the middle of the tube furnace, and pre-oxidize with air. , heated to 850°C, kept for 4h, and finally cooled to room temperature under the protection of inert gas to obtain the fiber-supported ferroelectric catalyst, which was named FePc(0:1)-CNFs.

[0047] The molar ratios of phthalocyanine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com