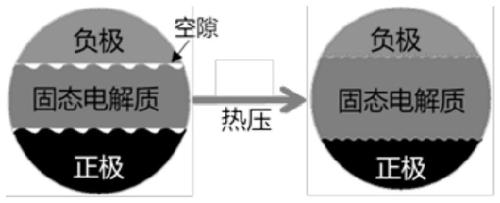

Battery cell hot-pressing integrally-molded solid-state battery and preparation method thereof

A solid-state battery and solid-state electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of large interface impedance and poor cycle stability, reduce interface impedance, improve effective contact, and ease interface The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation of the positive electrode: the positive electrode slurry containing polymer is coated on the positive electrode current collector to prepare the positive electrode containing polymer; the positive electrode active material, polymer, lithium salt, inorganic electrolyte, conductive agent, positive electrode binder and organic solvent Mixing in a certain proportion, ball milling or stirring to obtain a positive electrode slurry with a certain viscosity, coating the positive electrode slurry on the positive electrode current collector, and drying to obtain a positive electrode containing polymer.

[0046] Preparation of the negative electrode: preparing the negative electrode or preparing the metal lithium negative electrode; mixing the negative electrode active material, the conductive agent, the negative electrode binder and the aqueous solvent to obtain the negative electrode slurry by ball milling or stirring, and coating the negative electrode slurry on the ...

Embodiment 1

[0122] a) Weigh 7g LiNi 0.85 Co 0.1 Al 0.05 O 2 , 0.44g SP, 7.3g PVDF, 4.38g NBR, 0.44g LiTFSI were mixed, 0.4g DMAC solvent was added, and the mixture was stirred at 35°C for 6 hours to obtain the positive electrode slurry. The positive electrode slurry was coated on the aluminum foil with a 0.3mm doctor blade and dried at 60°C , Then vacuum drying at 100°C for 12h.

[0123] b) Weigh 5g graphite, 0.29gSP, 3.27gCMC, 0.62gSBR, 3.5g water and mix them with ball milling or stirring at room temperature to obtain the negative electrode slurry, and then use a 0.2mm spatula to coat the negative electrode slurry on the copper foil, 80℃ Dry, and then vacuum dry at 120°C for 12 hours.

[0124] c) Weigh 3g NBR, 1.5g LiTFSI, 0.05g succinonitrile in 20g THF, stir at 25°C to obtain a uniform solid electrolyte solution.

[0125] d) Coating the solid electrolyte solution obtained in c) on the negative electrode obtained in b) and drying at 40° C. for 8 hours.

[0126] e) Weigh 3g NBR, 7g LiTFSI, 6g ...

Embodiment 2

[0130] a) Weigh 7g LiNi 0.85 Co 0.1 Al 0.05 O 2 , 0.16g SP, 3.89g NBR, 0.23g LiTFSI were mixed and added 3g DMAC solvent, stirred at 35°C for 6h to obtain the positive electrode slurry. Use a 0.3mm doctor blade to coat the positive electrode slurry on the aluminum foil, dry at 60°C, and then vacuum at 100°C Dry for 12h.

[0131] b) Weigh 5g graphite, 0.11gSP, 1.17gCMC, 0.11gSBR, 5g water and mix them with ball milling or stirring at room temperature to obtain the negative electrode slurry, and then use a 0.2mm scraper to coat the negative electrode slurry on the copper foil, and bake at 80℃ After drying, vacuum drying at 120°C for 12 hours.

[0132] c) Weigh 3g of NBR and 1.5g of LiTFSI, dissolve in 25g of DMAC, stir at 25°C to obtain a uniform solid electrolyte solution.

[0133] d) Coating the solid electrolyte solution obtained in c) on the negative electrode obtained in b) and drying at 60° C. for 8 hours.

[0134] e) Weigh 3g of NBR, 3g of LiTFSI, 6g of LLZTO, 5mg of polymethyls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com