Connecting shell type solidification temperature measuring device

A temperature measuring device and shell-type technology, applied in the field of temperature measurement, can solve the problems of high cost, long thermal response time, inability to realize complex layout and continuous temperature measurement, and achieve the effect of flexible loading and unloading and low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

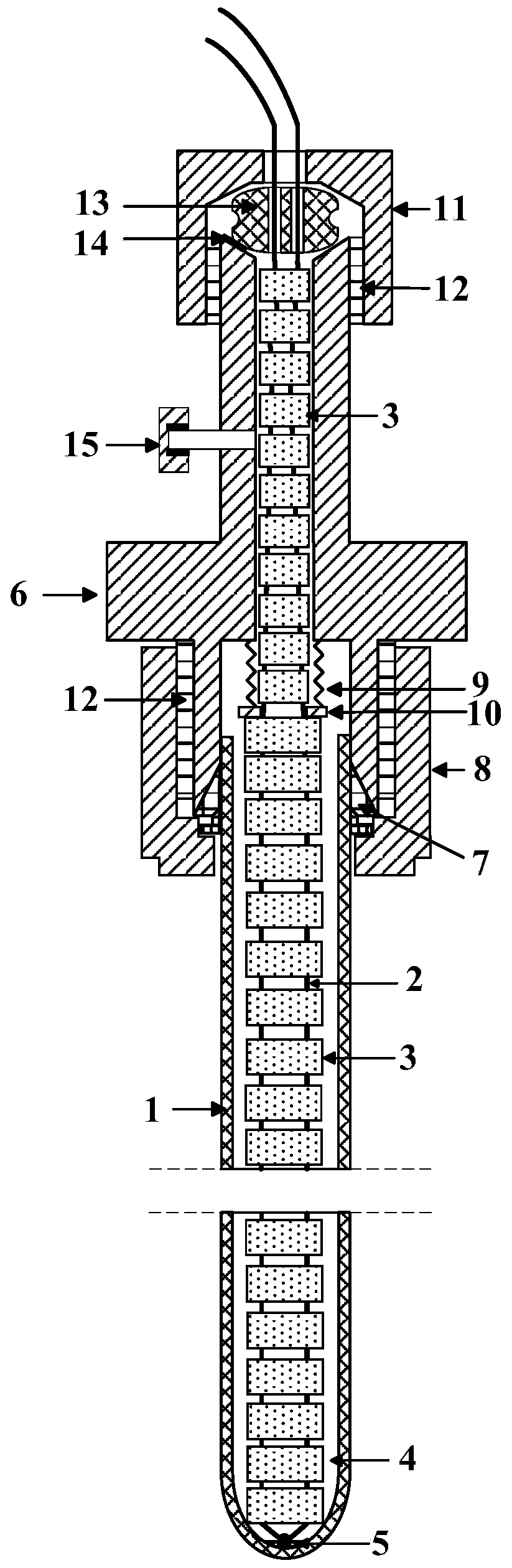

[0048] Such as figure 1 As shown, a shell-type solidification temperature measuring device includes an outer sheath extending into the sensing area, and a shell-type temperature measuring component housed in the outer sheath to sense the temperature in the sensing area ,Also includes:

[0049] The elastic component is press-fitted with the shell-type temperature measuring component and exerts a downward axial thrust on the shell-type temperature measuring component, so that the bottom end of the shell-type temperature measuring component is in contact with the bottom inner wall of the outer sheath;

[0050] Metal tin 5, when the temperature is measured, changes from a solid phase to a liquid phase, and then fills the inner wall of the bottom end of the outer sheath and submerges the bottom end of the shell-type temperature measurement component.

[0051] The concept of the present invention is: when measuring at 1000°C and above and in the field of solidification temperature ...

Embodiment 2

[0057] Such as figure 1 As shown, on the basis of the above embodiments, preferably, the present invention obtains a response sensitivity compatible with the cooling rate during the solidification process by adjusting the thickness of the sheath and the state of the gap between the sheaths.

[0058] The shell-type temperature measurement assembly includes:

[0059] a tungsten-rhenium wire 2 housed in the outer sheath to sense the temperature in said sensing region,

[0060] Cylindrical ceramic beads 3 are accommodated in the outer sheath, tungsten-rhenium wires 2 run through the cylindrical ceramic beads 3,

[0061] The elastic component is pressed against the cylindrical ceramic bead 3;

[0062] The bottom end of the outer sheath is configured as a spherical shell structure, and the temperature measuring node at the bottom end of the tungsten-rhenium wire 2 is in contact with the inner wall of the bottom end of the outer sheath;

[0063] The bottom end of the tungsten-rhen...

Embodiment 3

[0070] Such as figure 1 As shown, on the basis of the above embodiments, preferably, since the tungsten-rhenium thermocouple is used as the sensing element, the tungsten-rhenium thermocouple can be used for high-temperature measurement, and can be used for high-temperature liquid after selecting a sheath suitable for the use environment The internal solidification temperature is measured, but after the temperature measurement is completed, it is embedded in the solidified liquid and cannot be taken out, making the tungsten-rhenium thermocouple unable to be reused. The particularity of the material of the tungsten-rhenium thermocouple and the high requirements of the manufacturing process make it expensive for one-time use in high-temperature liquid solidification temperature measurement. The present invention adopts a detachable double sheath structure, so that only the outer sheath remains in the solidification medium after the solidification temperature measurement is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com