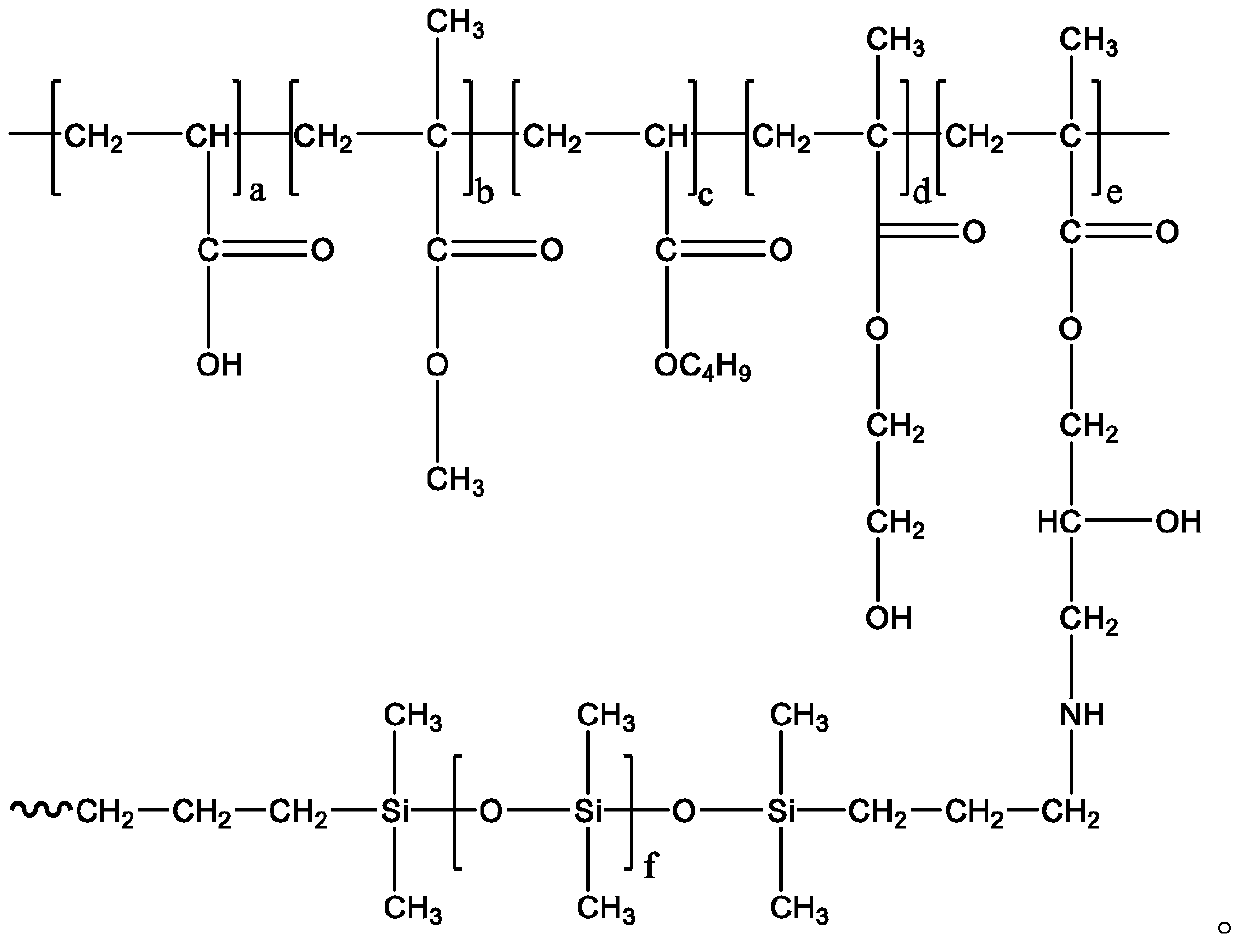

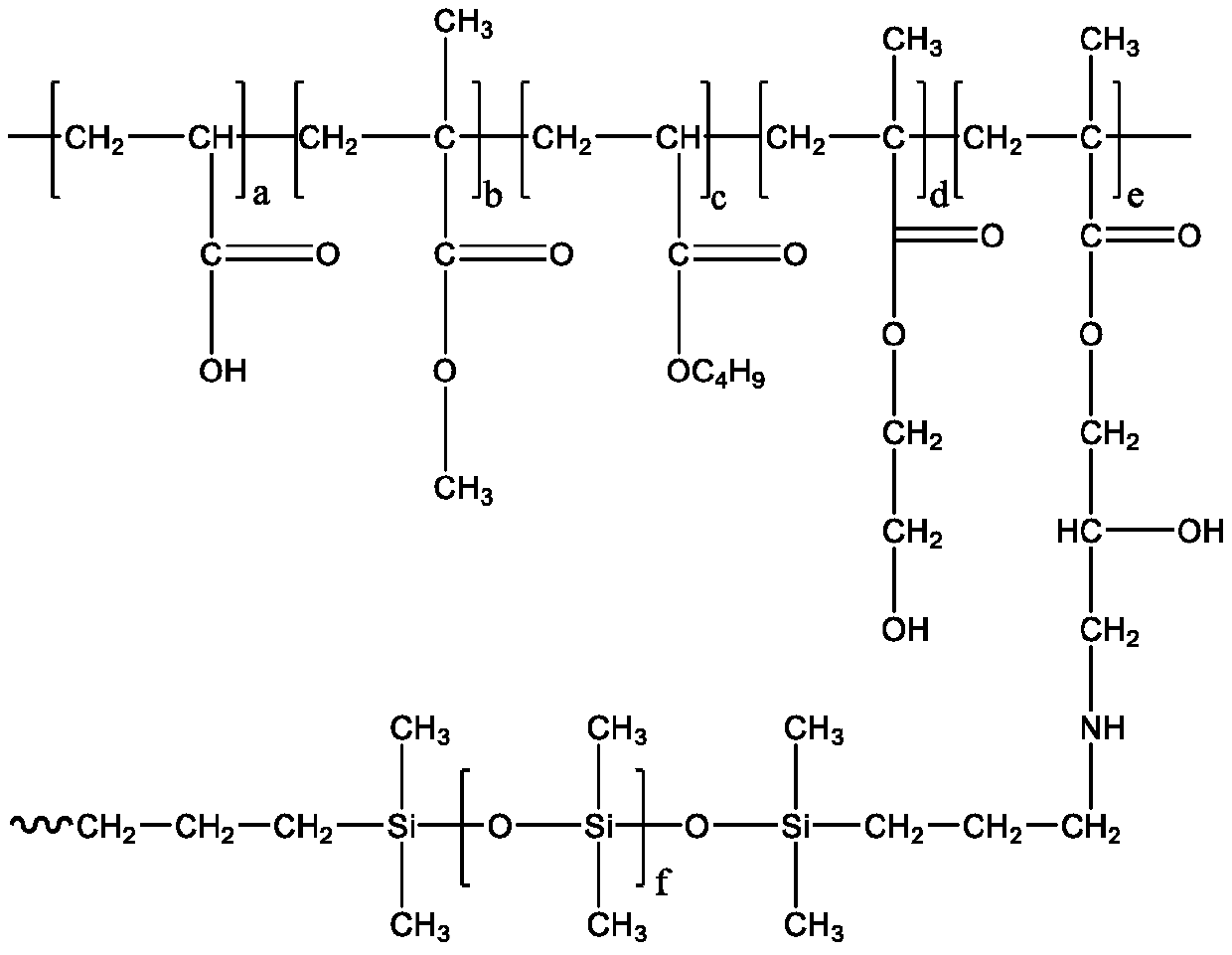

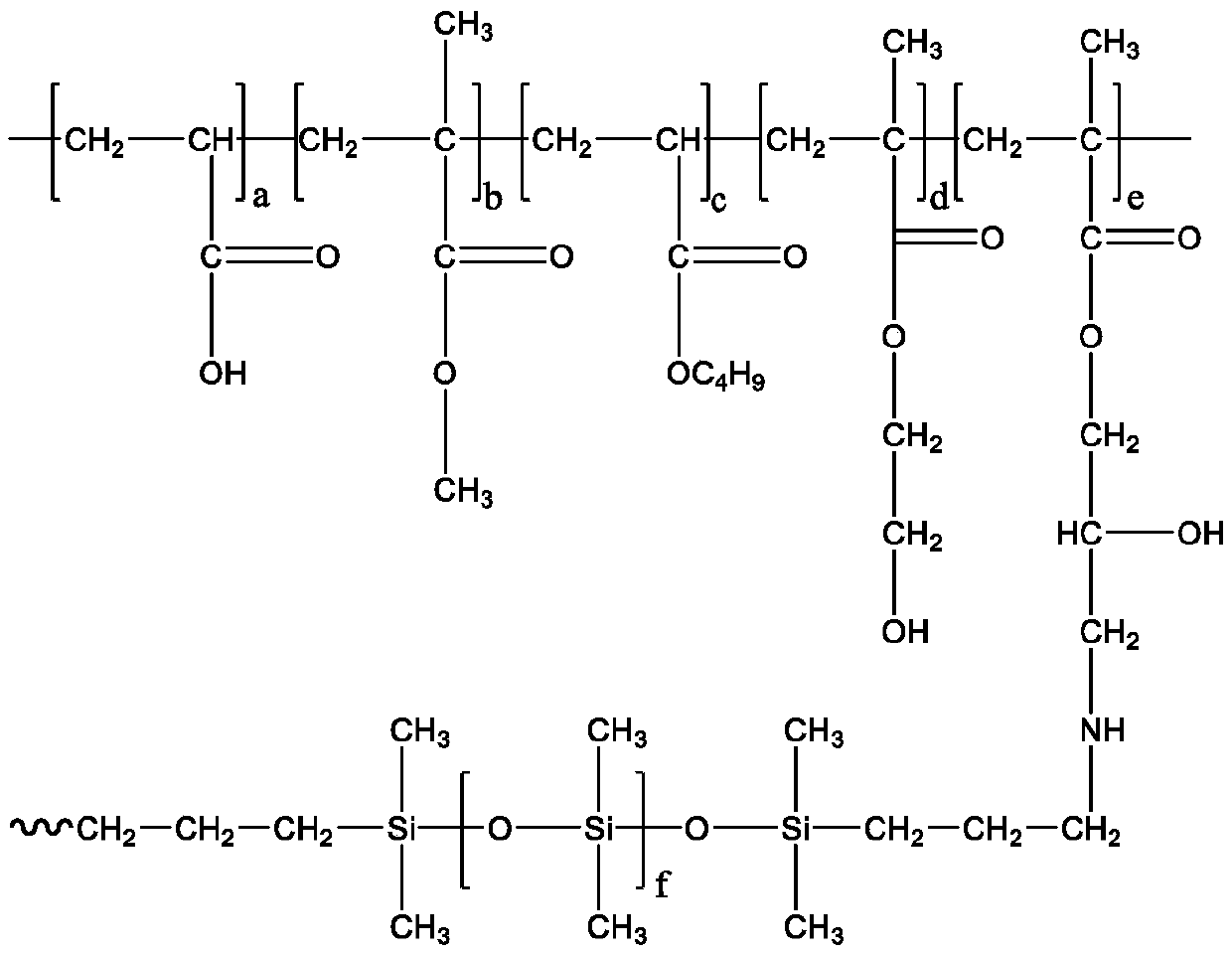

Preparation method of novel amino silicone oil modified acrylate anti-doodling emulsion

A technology of acrylate and amino silicone oil, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., and can solve the problems of low silicone introduction, volatile organic compound pollution, difficult polymerization of silicone monomers, etc. problems, to achieve the effect of green environmental protection and stable structure of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 30g of deionized water and 1.8g of composite emulsifier to the reactor, stir at 400rpm for 20 minutes, then dropwise add 25g of methyl methacrylate monomer, 16g of butyl acrylate monomer, and 1.6g of acrylic acid The mixture of the monomer, 20 g of hydroxyethyl methacrylate monomer, and 2.4 g of glycidyl methacrylate monomer was added dropwise for 40 minutes, and stirred for 60 minutes after the drop was completed to prepare an acrylate pre-emulsion.

[0028] Add the deionized water of 6g pre-emulsion, 0.8g emulsifier, 0.1g potassium persulfate and 50g in reactor, drop the pre-emulsion of 78g and 0.2g potassium persulfate (dissolve in 8g deionized water), Polymerize at 80°C for 2 hours, keep the temperature for 80 minutes after dripping, and lower to normal temperature to prepare an acrylate emulsion containing epoxy groups.

[0029] Add 0.048g of 1,3-bis(3-aminopropyl)-tetramethyldisiloxane, 48g of octamethylcyclotetrasiloxane (D4), 0.006g of catalyst, 0.3g Accele...

Embodiment 2

[0032] Add 24g of deionized water and 1.5g of composite emulsifier to the reactor, stir at 500rpm for 20 minutes, then dropwise add 30g of methyl methacrylate monomer, 12g of butyl acrylate monomer, and 1.8g of acrylic acid The mixture of monomers, 16 g of hydroxyethyl methacrylate monomer and 1.8 g of glycidyl methacrylate monomer was added dropwise for 60 minutes, and stirred for 45 minutes after the completion of the dropping to prepare an acrylate pre-emulsion.

[0033] Add the deionized water of the emulsifying agent of 8g pre-emulsion, 1g, 0.12g ammonium persulfate and 54g in reactor, drop the pre-emulsion of 76g and the ammonium persulfate of 0.24g (dissolve in 12g deionized water), in Polymerize at 85°C for 3 hours, keep the temperature for 60 minutes after dripping, and lower to normal temperature to prepare an acrylate emulsion containing epoxy groups.

[0034] Add 0.096g of 1,3-bis(3-aminopropyl)-tetramethyldisiloxane, 42g of octamethylcyclotetrasiloxane (D4), 0.008...

Embodiment 3

[0037] Add 18g of deionized water and 1.2g of composite emulsifier to the reaction kettle, stir for 40 minutes at 600rpm, then dropwise add 35g of methyl methacrylate monomer, 8g of butyl acrylate monomer, 2g of acrylic acid mono Body, the mixture of 12g of hydroxyethyl methacrylate monomer and 1.2g of glycidyl methacrylate monomer was added dropwise for 80 minutes, and stirred for 30 minutes after the drop was completed to prepare an acrylate pre-emulsion.

[0038] Add 10g pre-emulsion, 1.2g emulsifier, 0.14g sodium persulfate and 58g deionized water in reactor, add dropwise 74g pre-emulsion and 0.28g sodium persulfate (dissolved in 16g deionized water), Polymerize at 90°C for 4 hours, keep the temperature for 40 minutes after dripping, and lower to normal temperature to prepare an acrylate emulsion containing epoxy groups.

[0039] Add 0.144g of 1,3-bis(3-aminopropyl)-tetramethyldisiloxane, 36g of octamethylcyclotetrasiloxane (D4), 0.01g of catalyst, 0.1g of Accelerator, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com