Method for preparing 1, 3-propylene glycol from glycerin

A technology of propylene glycol and glycerin, applied in the direction of elimination of hydroxyl groups, chemical instruments and methods, feeding devices, etc., can solve the problems of limited industrial application prospects, difficult glycerin selectivity, low conversion rate of glycerin, etc., to improve catalytic efficiency and The effect of improving productivity, improving mixing efficiency, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

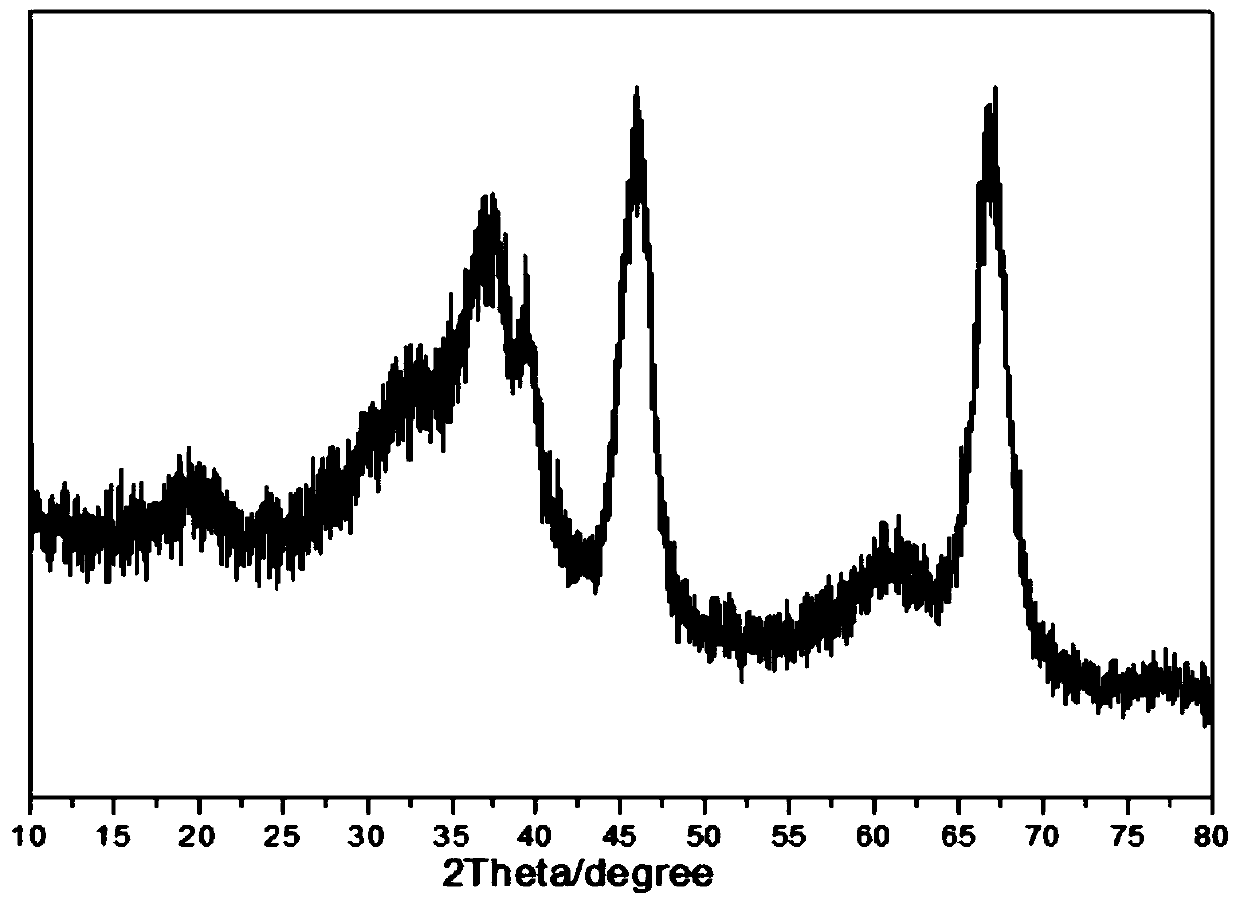

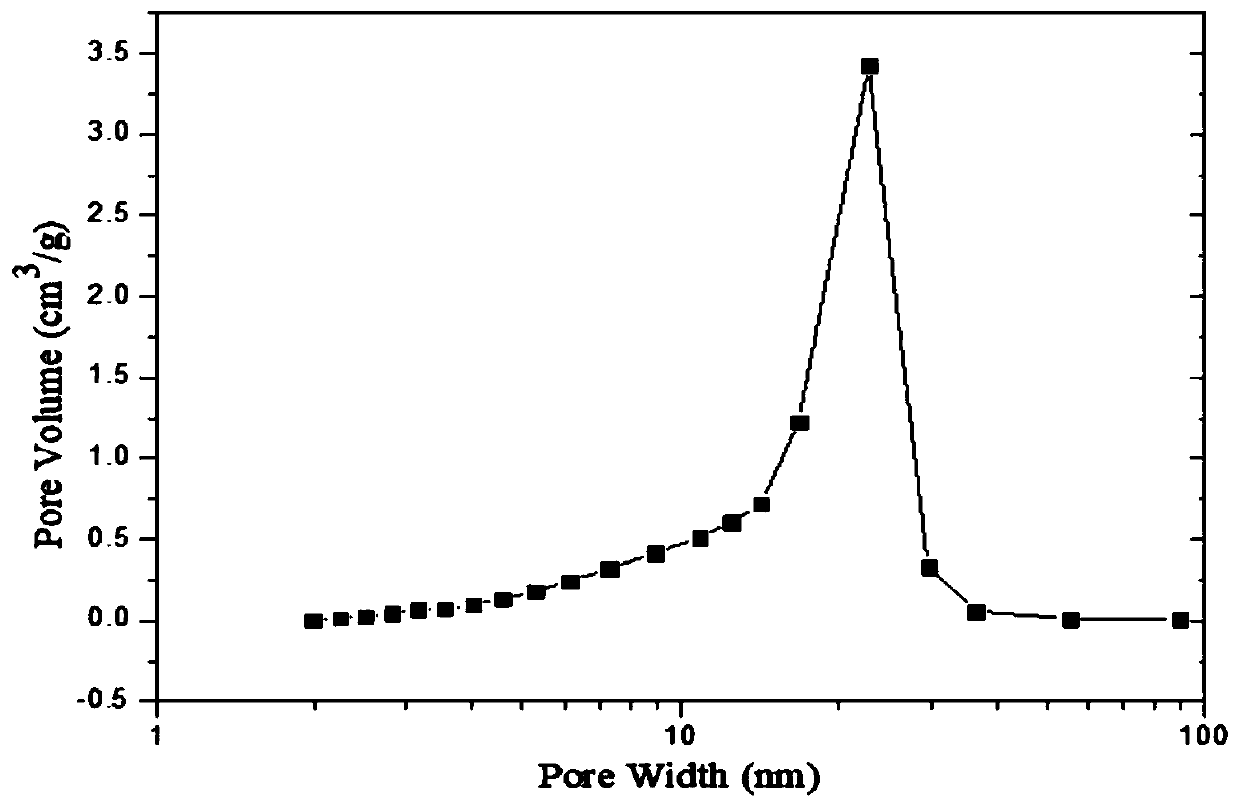

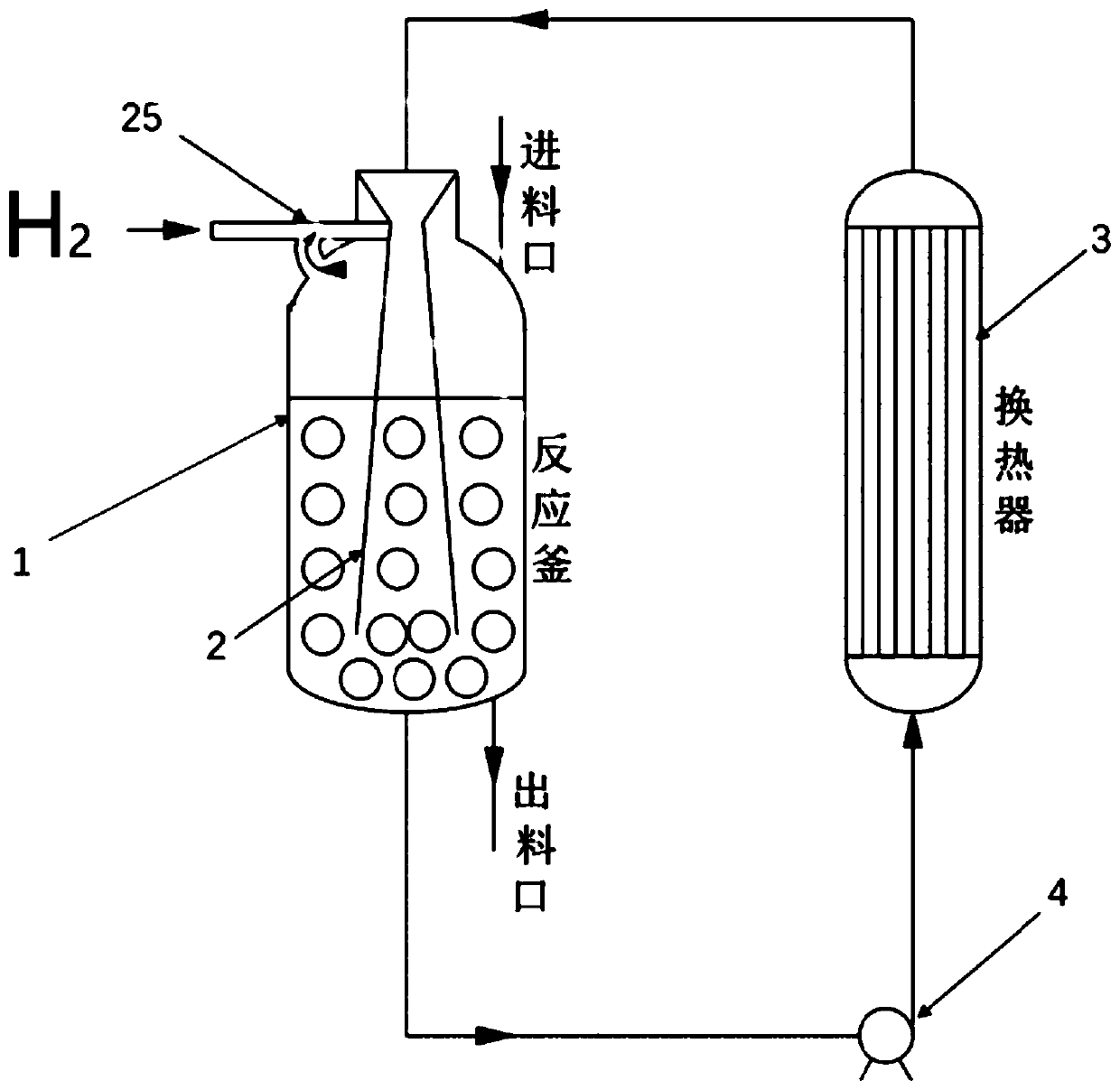

Embodiment 1

[0050] In a 5L loop reactor (reactor volume 5L), add 3000g of 30wt% glycerol methanol solution, add the catalyst Pt / WO pre-reduced by hydrogen at 200°C for 2h 3 / Al 2 o 3 The powder is 36g, that is, the relative ratio of the catalyst to the reactant glycerol is 4wt%. Catalyst preparation raw material Al 2 o 3 The amount of powder added and the amount of ammonium tungstate solution added in WO 3 / Al 2 o 3 The mass ratio of 8:100 metering, H 2 PtCl 6 The amount of addition is based on the mass of element Pt in WO 3 / Al 2 o 3 3% metering of sample mass. Introduce hydrogen into the reactor through the air inlet to a system pressure of 1 MPa, turn on the circulation pump to allow the liquid in the kettle to flow slowly, vent, and repeat six times to replace the air in the loop reactor to a preset reaction temperature of 170°C (heating time is about 15min) ) immediately after filling with hydrogen to a reaction pressure of 3MPa, adjust the circulation pump 4 to a flow ra...

Embodiment 2

[0053] In a 5L loop reactor (reactor volume 5L), add 3000g of 30wt% glycerol methanol solution, add the catalyst Pt / WO pre-reduced by hydrogen at 200°C for 2h 3 / Al 2 o 3 The powder is 36g, that is, the relative ratio of the catalyst to the reactant glycerol is 4wt%. Catalyst preparation raw material Al 2 o 3 The amount of powder added and the amount of ammonium tungstate solution added in WO 3 / Al 2 o 3 The mass ratio of 18:100 metering, H 2 PtCl 6 The amount of addition is based on the mass of element Pt in WO 3 / Al 2 o 3 1.5% metering of sample mass. Introduce hydrogen into the reactor through the air inlet to a system pressure of 1 MPa, turn on the circulation pump to allow the liquid in the kettle to flow slowly, vent, and repeat six times to replace the air in the loop reactor to a preset reaction temperature of 170°C (heating time is about 15min) ) immediately after filling with hydrogen to a reaction pressure of 3MPa, adjust the circulation pump 4 to a flow ...

Embodiment 3

[0056] In a 5L loop reactor (reactor volume 5L), add 3000g of 30wt% glycerol methanol solution, add the catalyst Pt / WO pre-reduced by hydrogen at 200°C for 2h 3 / Al 2 o 3 The powder is 36g, that is, the relative ratio of the catalyst to the reactant glycerol is 4wt%. Al in raw materials for catalyst preparation 2 o 3 The amount of powder added and the amount of ammonium tungstate solution added in WO 3 / Al 2 o 3 The mass ratio of 28:100 metering, H 2 PtCl 6 The amount of addition is based on the mass of element Pt in WO 3 / Al 2 o 3 1.5% metering of sample mass. Introduce hydrogen into the reactor through the air inlet to a system pressure of 1 MPa, turn on the circulation pump to allow the liquid in the kettle to flow slowly, vent, and repeat six times to replace the air in the loop reactor to a preset reaction temperature of 170°C (heating time is about 15min) ) immediately after filling with hydrogen to a reaction pressure of 3MPa, adjust the circulation pump 4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com