Polysulfate flat ultrafiltration membrane and preparation method thereof

A polysulfate, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of inapplicability, complex membrane formation methods, and low membrane flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

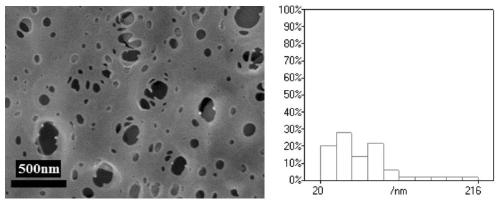

[0033] Add 3.0g of polysulfate (Mn=60,000g / mol) into 27.0g of N-methylpyrrolidone (10% polymer concentration), stir at 80°C until completely dissolved, cool to room temperature, and centrifuge at 10,000rpm to defoam. Scratch coating on a glass plate, immediately immerse in a deionized water coagulation bath at 10°C to solidify to form a film, and after the solvent in the film is completely replaced by deionized water, continue to soak it in deionized water for storage until use. The tensile strength of the membrane is 1.35MPa, the average pore size of the membrane surface is 44.2nm, and the pure water flux is 356.9Lm at room temperature and 0.1MPa pressure -2 h -1 .

Embodiment 2

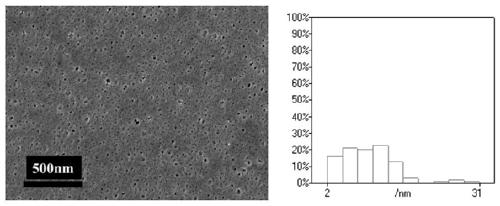

[0035] Add 0.3g of polyvinylpyrrolidone K30 and 1.5g of PEG-200 to 24.3g of N,N-dimethylformamide, dissolve completely at 30°C, then add 5.7g of polysulfate (Mn=90,000g / mol), at 80°C After standing still for degassing, scrape it on a glass plate, and immediately immerse it into a deionized water coagulation bath to solidify to form a film. The temperature of the coagulation bath is 15°C. After the solvent in the film is completely replaced by deionized water, continue to It was soaked in deionized water and stored until use. The film tensile strength was 1.95 MPa. At room temperature and 0.1MPa pressure, the pure water flux is 217Lm -2 h -1 , The retention rate of 1.0g / L BSA (0.1M PBS buffer solution) is 91%. After cross-flow filtration for 30 minutes with BSA as the model pollutant, backwash for 5 minutes, the flux recovery rate was 81.3%.

Embodiment 3

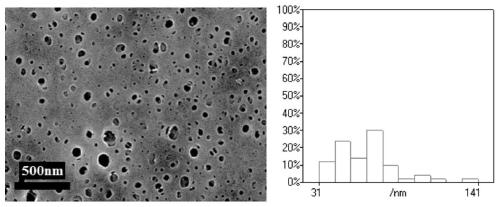

[0037] Add 5.7g polysulfate (Mn=60,000g / mol) into 24.3g N,N-dimethylacetamide (19% polymer concentration), stir at 80°C until completely dissolved, cool to room temperature, 10000rpm Centrifugal defoaming, scrape coating on a glass plate, immediately immerse in a deionized water coagulation bath to solidify to form a film, the temperature of the coagulation bath is 20°C, after the solvent in the film is completely replaced by deionized water, continue to soak it in deionized water Save until use. The tensile strength of the membrane is 2.05MPa, the average pore diameter of the membrane surface is 72nm, and the pure water flux is 187Lm under room temperature and 0.1MPa pressure -2 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com