Hollow spherical tantalum-doped Cu<7>S<4> material as well as preparation method and application thereof

A spherical and hollow technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of large amount of ruthenium oxide, failure to modify the electronic structure, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

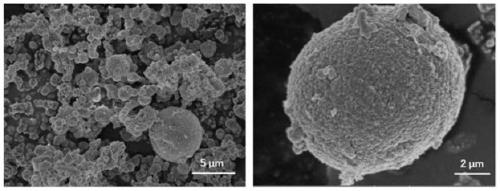

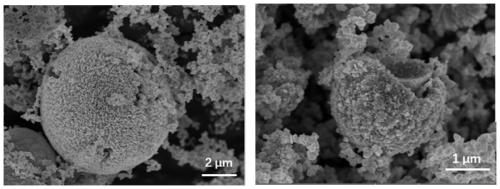

[0043] A. Dissolve 5mmol copper nitrate, 0.5mmol tantalum pentachloride and 0.2g sodium lauryl sulfate in 20ml ethylene glycol to form a mixed solution A, dissolve 0.2g sodium hydroxide in 10ml ethylene glycol solution to form a mixed solution Solution B, uniformly mix solution A and solution B to obtain mixed solution C; transfer to a high-pressure reactor, react at 180°C for 12 hours, filter, wash the filter cake with deionized water until neutral, and dry to obtain the precursor powder ;

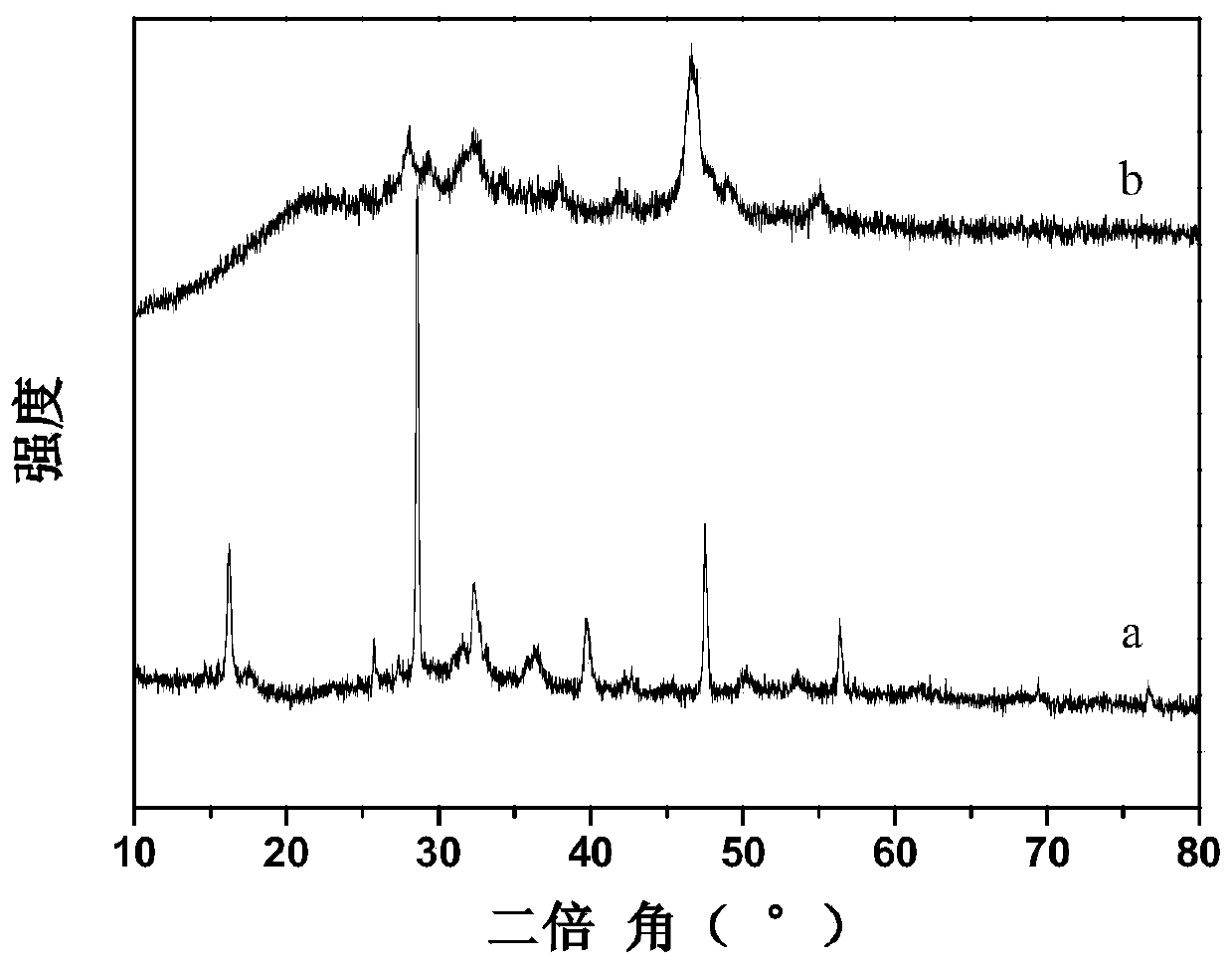

[0044] B. Evenly disperse 30 mg of the precursor powder obtained in step A in 30 ml of sodium sulfide ethylene glycol solution with a sodium sulfide content of 0.1 mol / L, and keep it in a water bath at 55°C for 3 hours at a constant temperature; filter and use the filter cake Wash with ionic water until neutral, and dry in vacuum for 12 hours to get Ta / Cu 7 S 4 Material. Determination of Ta / Cu by X-ray Photoelectron Spectroscopy 7 S 4 The content of each element, the results are show...

Embodiment 2

[0048] A. Dissolve 5mmol copper nitrate, 0.625mmol tantalum pentachloride and 0.15g sodium lauryl sulfate in 20ml ethylene glycol to form a mixed solution A, dissolve 0.2g sodium hydroxide in 10ml ethylene glycol solution to form a mixed solution For solution B, mix solution A and solution B uniformly to obtain mixed solution C; transfer to a high-pressure reactor, react at 160°C for 10 hours, filter, wash the filter cake with deionized water until neutral, and dry to obtain the precursor powder ;

[0049] B. Evenly disperse 40 mg of the precursor powder obtained in step A in 30 ml of ethylene glycol solution of sodium sulfide with a sodium sulfide content of 0.1 mol / L, and keep it in a water bath at 55°C for 4 hours at a constant temperature; filter and use the filter cake Wash with ionic water until neutral, and dry in vacuum for 12 hours to get Ta / Cu 7 S 4 Material. Determination of Ta / Cu by X-ray Photoelectron Spectroscopy 7 S 4 The content of each element in it, amon...

Embodiment 3

[0051] A. Dissolve 5mmol copper nitrate, 0.5mmol tantalum pentachloride and 0.15g sodium lauryl sulfate in 20ml ethylene glycol to form a mixed solution A, dissolve 0.16g sodium hydroxide in 10ml ethylene glycol solution to form a mixed solution For solution B, mix solution A and solution B evenly to obtain mixed solution C; transfer to a high-pressure reactor, react at 160°C for 8 hours, filter, wash the filter cake with deionized water until neutral, and dry to obtain the precursor powder ;

[0052] B. Evenly disperse 50 mg of the precursor powder obtained in step A in 30 ml of ethylene glycol solution of sodium sulfide with a sodium sulfide content of 0.1 mol / L, and keep it at a constant temperature for 2.5 hours in a water bath at 55° C.; filter and use the filter cake Wash with deionized water until neutral, and dry in vacuum for 8 hours to obtain Ta / Cu 7 S 4 Material. Determination of Ta / Cu by X-ray Photoelectron Spectroscopy 7 S 4 The content of each element in it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com