R-T-B series permanent magnet material as well as preparation method and application thereof

A technology of R-T-B and permanent magnet materials, which is applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., and can solve problems such as poor consistency and magnet performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The raw materials used for preparing the R-T-B series permanent magnet material in the present embodiment are as shown in Table 1, and the process of its preparation is as follows:

[0083] (1) Melting: according to the formula shown in Table 1, take the prepared raw materials and put them into an alumina crucible, and carry out the melting process at a temperature of 1500°C in a high-frequency vacuum induction melting furnace under the condition that the vacuum degree is less than 0.02Pa. Vacuum melting.

[0084] (2) Casting: Ar gas is introduced into the smelting furnace after vacuum smelting to make the air pressure reach 55,000 Pa, and then casting is carried out, and the melt is passed through a copper roller with a speed of 29 rpm to obtain a quick-setting with a thickness of 0.12-0.35mm Alloy sheets, during the casting process, the copper rollers need to be fed with chilled water, and the water inlet temperature is ≤25°C (as shown in Table 2); 2 ℃ / sec-10 4 °C / s...

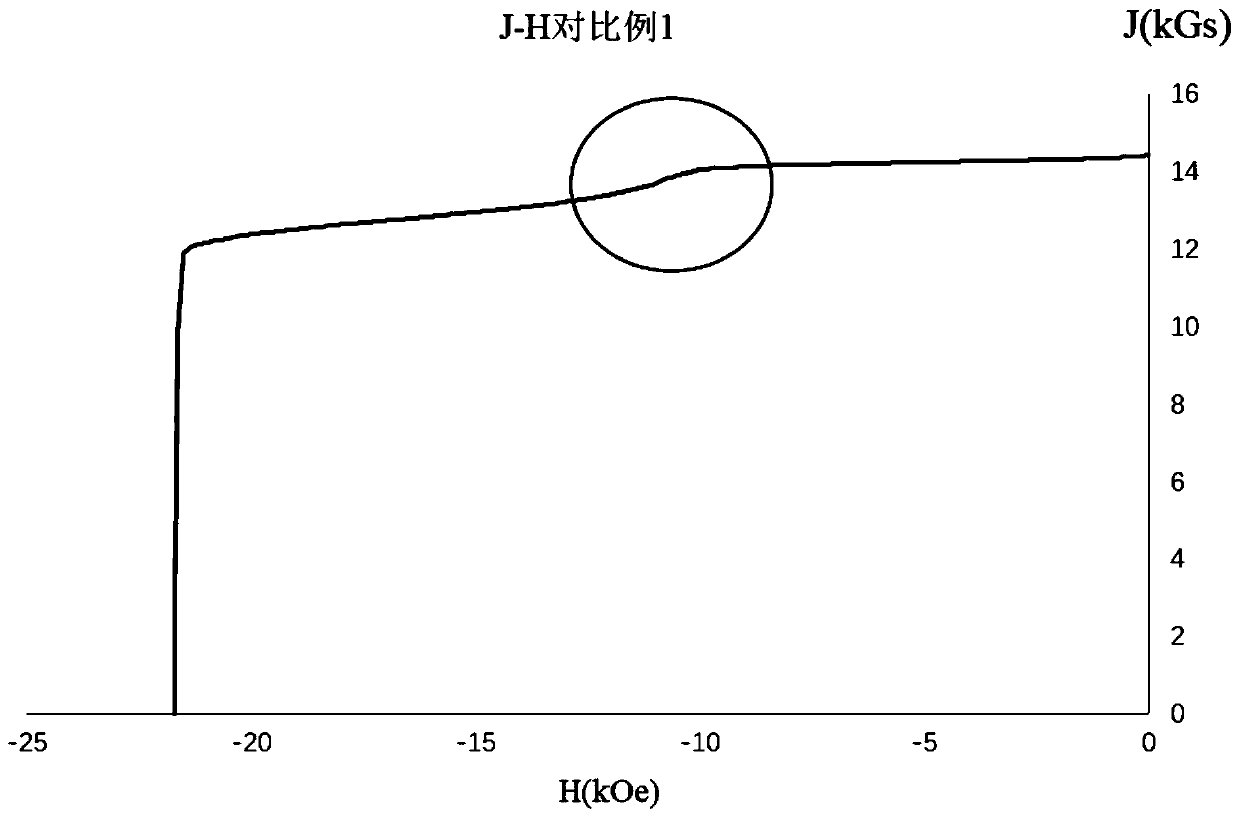

Embodiment 2~20、 comparative example 1~12

[0103] Raw materials were prepared according to the formula shown in Table 1. Except for the conditions shown in Table 2, other process conditions were the same as in Example 1 to obtain the R-T-B series permanent magnet material.

[0104] Table 2

[0105]

[0106]

[0107]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com