Method for determining content of niobium, tantalum, phosphorus, manganese, silicon, aluminum and copper in ferroniobium alloy

A niobium-iron alloy and measurement method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of platinum-gold crucible alloy single-element corrosion and undetectable problems, so as to ensure accuracy, high accuracy, and reduce occupational health hazards effect of factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

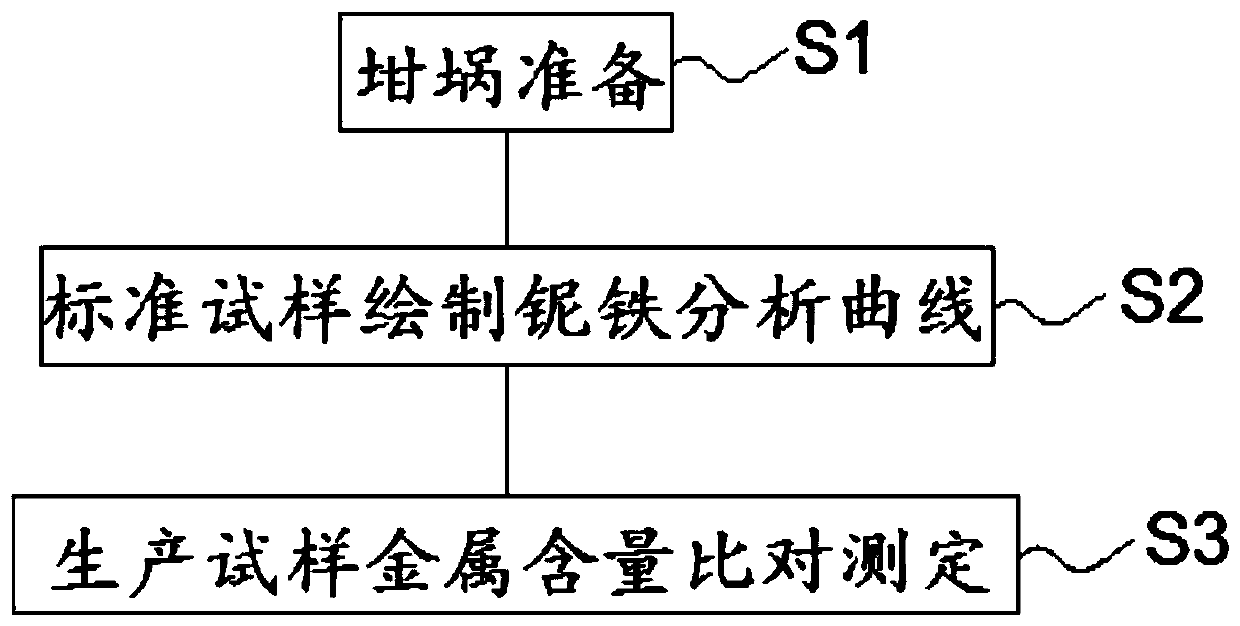

[0030] see figure 1 , a method for determining the content of niobium, tantalum, phosphorus, manganese, silicon, aluminum and copper in ferroniobium alloys. The following components are selected in parts by weight, and the determination steps include:

[0031] S1: Crucible preparation, choose a platinum crucible, weigh 4-6 parts of lithium tetraborate, melt it in a high-frequency melting machine at 950°C or in a muffle furnace, and rotate the platinum crucible to evenly cover the inner wall of the platinum crucible with anhydrous lithium tetraborate , forming a protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com