Thermoplastic wood-plastic composite packaging plastic and preparation method thereof

A wood-plastic composite and packaging plastic technology, which is applied in the field of packaging materials, can solve the problems of difficult thermal plasticization processing packaging films, etc., and achieve the effects of easy large-scale promotion and use, improved packaging quality, and good texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

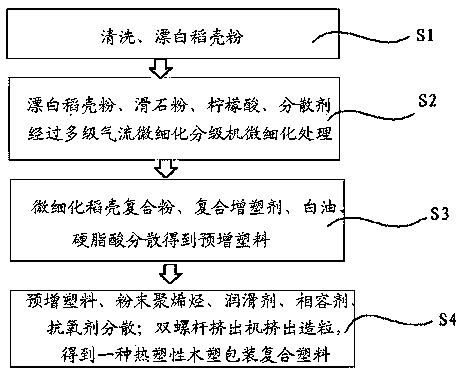

Method used

Image

Examples

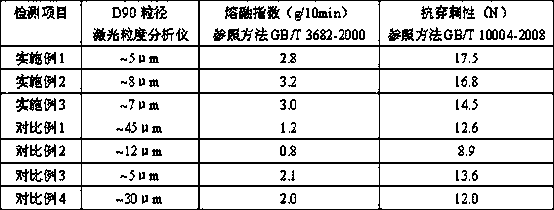

Embodiment 1

[0036] S1: First, wash the rice husks with clean water to remove impurities such as soil, sand and gravel; then soak them in 200mL / L hydrogen peroxide solution for re-bleaching for 10 minutes, filter to remove the hydrogen peroxide solution, wash them again with clean water for 3 times, and then Drying at 80°C to obtain bleached rice husk powder;

[0037] S2: Mix bleached rice husk powder with 1250-mesh fine talcum powder, citric acid, and dispersant ethylene bis fatty acid amide at a mass ratio of 6:1:0.3:0.05, and pass through the two-stage vortex airflow micromachine, of which the first-stage airflow The rotating speed of the crushing knife is 600rpm, and the rotating speed of the primary classification is 900rpm; the rotating speed of the secondary airflow crushing knife is 1500rpm, and the rotating speed of the secondary classification is 1200rpm; through the high-speed rotating moving knife, a strong airflow is generated to make the material appear in a suspended flow in ...

Embodiment 2

[0042] S1: First, wash the rice husk with clean water to remove impurities such as soil, sand and gravel; then soak it in 200mL / L hydrogen peroxide solution for re-bleaching for 20 minutes, filter to remove the hydrogen peroxide solution, wash it again with clean water for 3 times, and then Drying at 80°C to obtain bleached rice husk powder;

[0043] S2: Mix bleached rice husk powder with 1250-mesh fine talcum powder, citric acid, and dispersant pentaerythritol stearate at a mass ratio of 6:1:0.3:0.1, and pass through the two-stage vortex airflow fine machine, of which the first-stage airflow The speed of the pulverizing knife is 800rpm, and the speed of the primary classification is 900rpm; the speed of the secondary airflow pulverizing knife is 1000rpm, and the speed of the secondary classification is 1200rpm; through the high-speed rotating moving knife, a strong airflow is generated to make the material appear in a suspended flow in the grinding chamber The air flow and th...

Embodiment 3

[0048] S1: First, wash the rice husk with clean water to remove impurities such as soil, sand and gravel; then soak it in 200mL / L hydrogen peroxide solution for re-bleaching for 20 minutes, filter to remove the hydrogen peroxide solution, wash it again with clean water for 3 times, and then Drying at 80°C to obtain bleached rice husk powder;

[0049] S2: Mix bleached rice husk powder with 1250-mesh fine talcum powder, citric acid, and dispersant ethylene bis fatty acid amide at a mass ratio of 6:1:0.2:0.1, and pass through a two-stage vortex airflow micromachine, of which the first-stage airflow The rotational speed of the pulverizing knife is 800rpm, and the rotational speed of the primary classification is 1000rpm; the rotational speed of the secondary airflow pulverizing knife is 1500rpm, and the rotational speed of the secondary classification is 1500rpm; through the high-speed rotating moving knife, a strong airflow is generated to make the material appear in a suspended f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com