Method for preparing arsenic trioxide from arsenic-rich slag

An arsenic trioxide and arsenic-rich technology, which is applied in the field of preparation of arsenic trioxide, can solve the problems of high reaction temperature and unsuitability for industrial production, and achieve the effects of low reaction temperature, good operability and application prospects, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

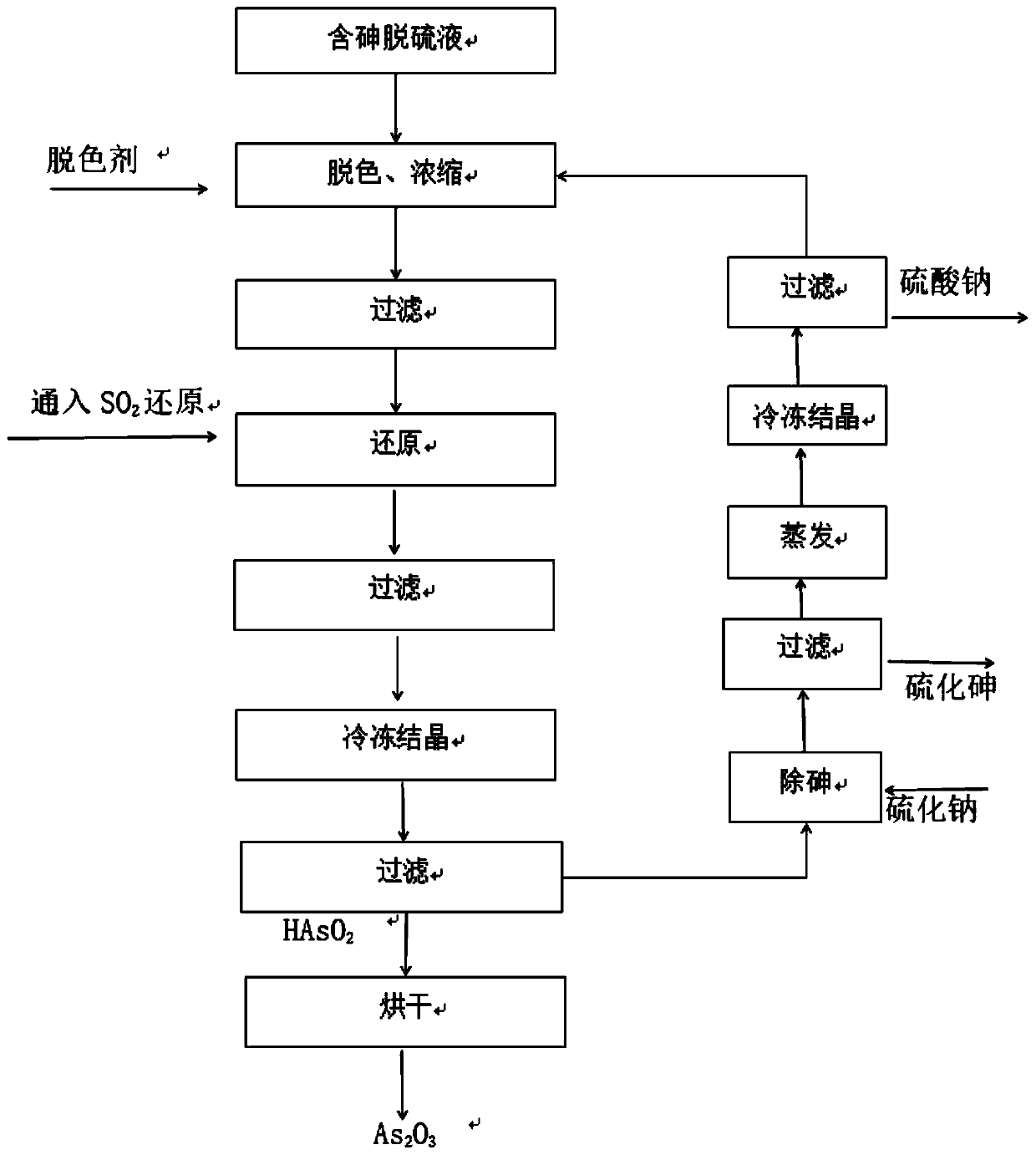

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing arsenic trioxide from arsenic-rich slag, comprising the steps of:

[0046] (1) Pretreatment of arsenic-rich slag: crushing and grinding the arsenic-rich slag into mineral powder, putting the mineral powder into a compound agent for leaching reaction, and then introducing air and oxygen to react. After the reaction, an oxidative desulfurization solution is obtained; After heating, evaporating and concentrating, add 2g / L decolorizing agent for decolorizing, and filter out the filter residue to obtain the pretreatment solution; the compounding agent is obtained by mixing NaOH and NaClO in a molar ratio of 4:3; the slag and The molar ratio of the compounding agent is 6:1; the decolorizing agent is a mixture of coconut shell activated carbon, coal-based activated carbon, and diatomaceous earth in a mass ratio of 8:2:1;

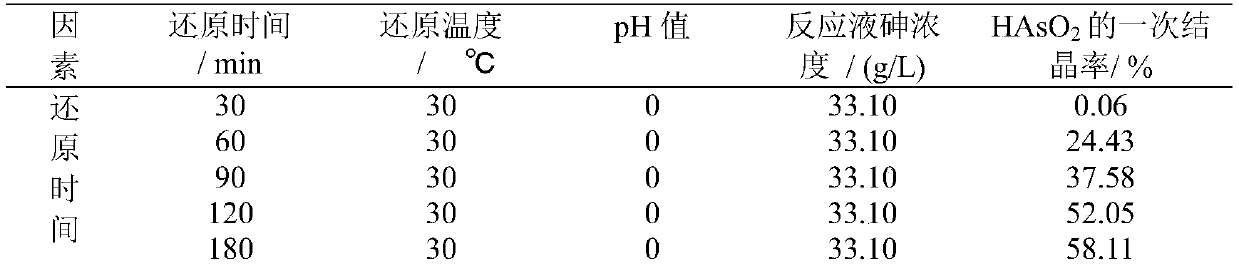

[0047] (2) Reduction process: After adjusting the pH of the pretreatment solution to 0, intermittently feed sulfur dioxide gas at a r...

Embodiment 2

[0054] A method for preparing arsenic trioxide from arsenic-rich slag, comprising the steps of:

[0055] (1) Pretreatment of arsenic-rich slag: crushing and grinding the arsenic-rich slag into mineral powder, putting the mineral powder into a compound agent for leaching reaction, and then introducing air and oxygen to react. After the reaction, an oxidative desulfurization solution is obtained; After heating, evaporating and concentrating, add 2.5g / L decolorizing agent for decolorization, and filter out the filter residue to obtain the pretreatment solution; the compounding agent is obtained by mixing NaOH and NaClO in a molar ratio of 5:4; the slag The molar ratio to the complexing agent is 18:1; the decolorizing agent is a mixture of coconut shell activated carbon, coal-based activated carbon, and diatomaceous earth in a mass ratio of 18:6:1;

[0056] (2) Reduction process: After adjusting the pH of the pretreatment solution to a value of 3, intermittently feed sulfur dioxid...

Embodiment 3

[0061] A method for preparing arsenic trioxide from arsenic-rich slag, comprising the steps of:

[0062] (1) Pretreatment of arsenic-rich slag: crushing and grinding the arsenic-rich slag into mineral powder, putting the mineral powder into a compound agent for leaching reaction, and then introducing air and oxygen to react. After the reaction, an oxidative desulfurization solution is obtained; After heating, evaporating and concentrating, add 2.2g / L decolorizing agent for decolorization, and filter out the filter residue to obtain the pretreatment solution; the compounding agent is obtained by mixing NaOH and NaClO according to a molar ratio of 4.5:3.7; the slag The molar ratio of the compounding agent is 12:1; the decolorizing agent is a mixture of coconut shell activated carbon, coal-based activated carbon, and diatomaceous earth in a mass ratio of 13:4:1;

[0063] (2) Reduction process: After adjusting the pH of the pretreatment solution to 2, intermittently feed sulfur di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com