Device and method for producing high-end graphite carbon material

A graphite carbon, high-end technology, applied in the field of equipment for the production of high-end graphite carbon materials, can solve the problems of unresolved needle coke operation fluctuations, unstable performance of needle coke products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

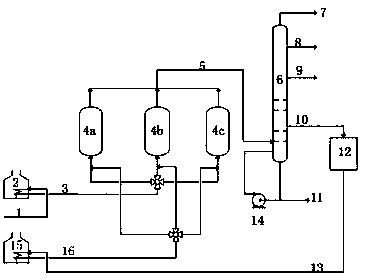

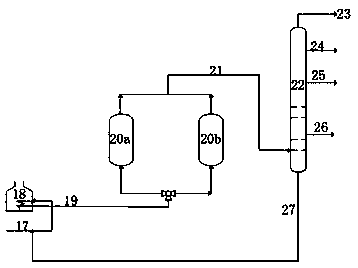

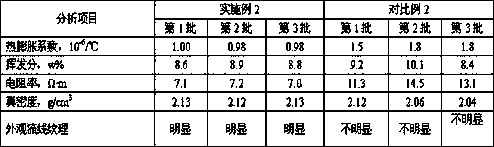

Embodiment 1

[0079] Using the refined catalytic oil slurry of a refinery as raw material, the specific properties of the refined oil slurry are shown in Table 1. The pressure at the top of the coking tower is 0.5 MPa, and the coking cycle of coking is 32 hours. According to the three-tower switching method provided by the present invention, the oil slurry When the coke charging time of the coke tower accounts for 50% of the total coke charging time, switch to coking light wax oil to continue coke charging, wherein the temperature at the outlet of heating furnace 1 in step (1) is 420°C-440°C heating-constant temperature process, The heating rate is 5°C / h, the constant temperature time is 12h, the gas velocity in the coke tower is controlled to be 0.05-0.08m / s, and the outlet temperature of the heating furnace 2 in step (2) is 460°C-490°C during the heating-constant temperature process, and the heating rate is 10°C / h, the constant temperature time is 13h, the gas velocity in the coke tower is...

Embodiment 2

[0087] Using the same device and raw materials as in Example 1, the pressure at the top of the coking tower is 0.8MPa, and the coking cycle of coking is 40h. According to the three-tower switching method provided by the present invention, the coke charging time of the coke tower with oil slurry accounts for the total coke charging time. At 50% of the time, switch to coking light wax oil and continue coke filling, wherein the outlet temperature of heating furnace 1 in step (1) is 400°C-460°C heating-constant temperature process, the heating rate is 4°C / h, and the constant temperature time is 5h, The gas velocity in the coke tower is controlled at 0.07-0.10m / s, and the outlet temperature of heating furnace 2 in step (2) is 470°C-510°C heating-constant temperature process, the heating rate is 10°C / h, and the constant temperature time is 16h. The gas velocity is controlled at 0.18-0.25m / s. In steps (1)~(5), the temperature of the 10% distillation point of the coking light wax oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com