A kind of coking system and coking method

一种焦化蜡油、焦化装置的技术,应用在生产针状焦的焦化系统,焦化系统领域,能够解决针状焦产品性能不稳定、没有解决针状焦操作波动等问题,达到降低热膨胀系数、质量提高、满足连续操作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

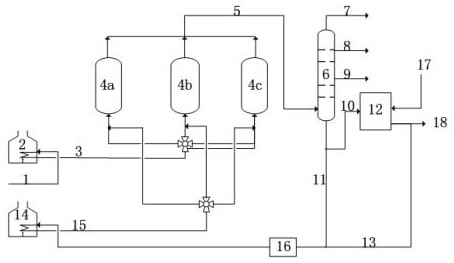

Embodiment 1

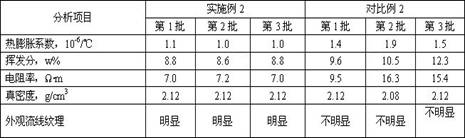

[0213] The catalytic oil slurry refined by a certain refinery is used as the coking raw material. The specific property analysis of the oil slurry is shown in Table 1. The pressure at the top of the coking tower is 0.5MPa, and the coking cycle of coking is 32h. According to the three-tower switching method provided by the present invention, the steps (1) The outlet temperature of the middle heating furnace 1 is 420°C-440°C heating-constant temperature process, the heating rate is 5°C / h, the constant temperature time is 12h, the gas velocity in the coke tower is controlled at 0.05-0.08m / s, step (2) The outlet temperature of the middle heating furnace 2 is 460°C-490°C heating-constant temperature process, the heating rate is 10°C / h, the constant temperature time is 13h, the gas velocity in the coke tower is controlled at 0.13-0.18m / s, steps (1) to (5 The temperature of the 10% distillation point of the coker wax oil in ) is 350°C, and the temperature of the 90% distillation point...

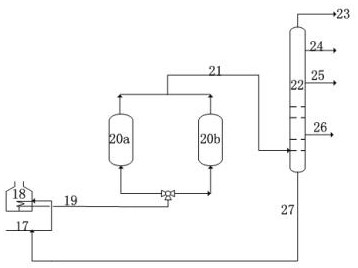

Embodiment 2

[0232] The same device and needle coke raw material as in Example 1 were used. The supplementary coke pulling raw material is coker wax oil from the separation tower 6 (temporarily stored in the coke pulling raw material storage tank 12), its 10% distillation point temperature is 330°C, 90% distillation point temperature is 480°C, its Rate B is 20%. The coke tower charging period T is 40h, the coke tower top pressure is 0.8MPa, the outlet temperature of heating furnace 2 is 400°C-460°C heating-constant temperature process, the heating rate is 4°C / h, and heating furnace 2 is charging the coke tower. , the gas velocity in the coke tower is controlled to be 0.07-0.10m / s, the outlet temperature of the furnace 14 is 470-510°C, the temperature rise rate is 10°C / h, and the gas velocity in the coke tower of the heating furnace 14 is controlled to be 0.18-0.18- 0.25m / s, coke-pulling raw materials (such as coke wax oil) during the coke charging process of the coke tower, the drawing ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com