Soft-bottom carpet prepared from recycled yarns and manufacturing method of soft-bottom carpet

A carpet and soft bottom technology, used in the manufacture of carpets, carpets, and final products, can solve the problems of secondary pollution of energy, consumption of large energy, physical damage to operators, etc., to achieve high comfort, soft material, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

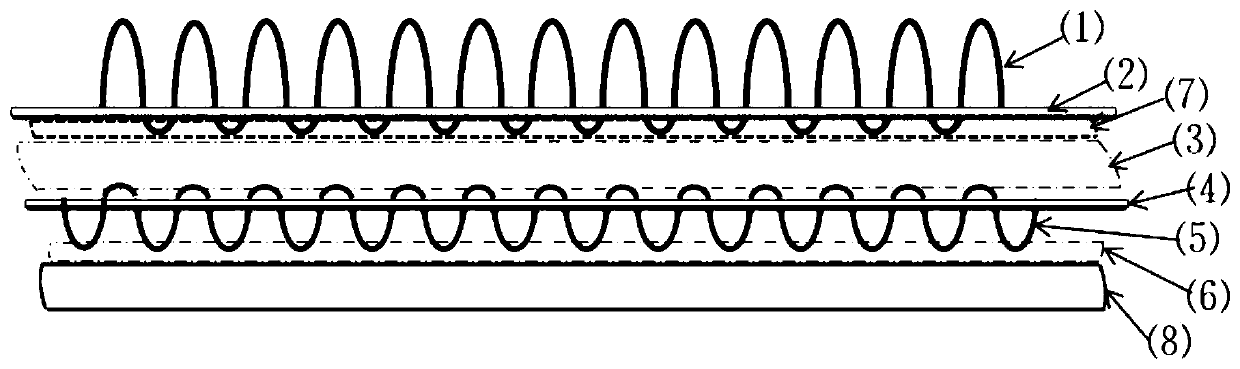

[0051] Embodiment 1: the above-mentioned method for manufacturing the soft bottom carpet that utilizes recycled yarns to prepare may further comprise the steps:

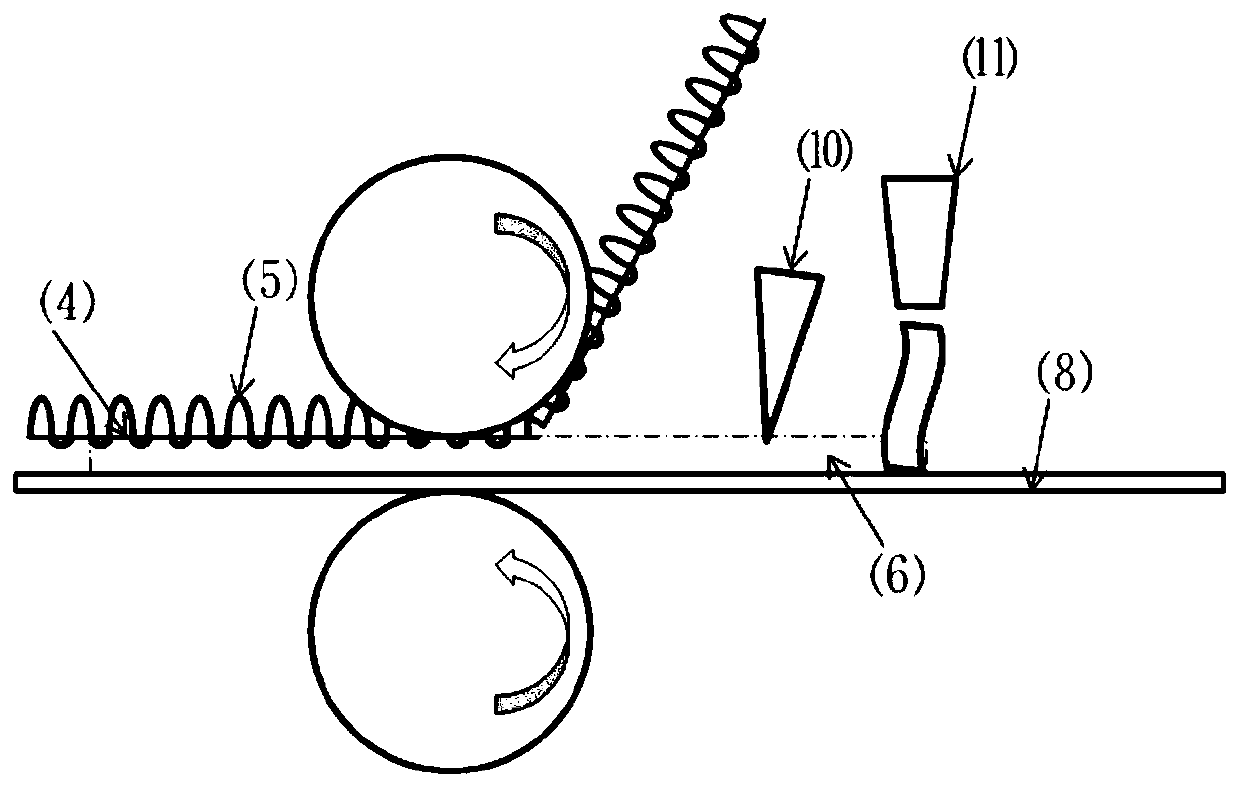

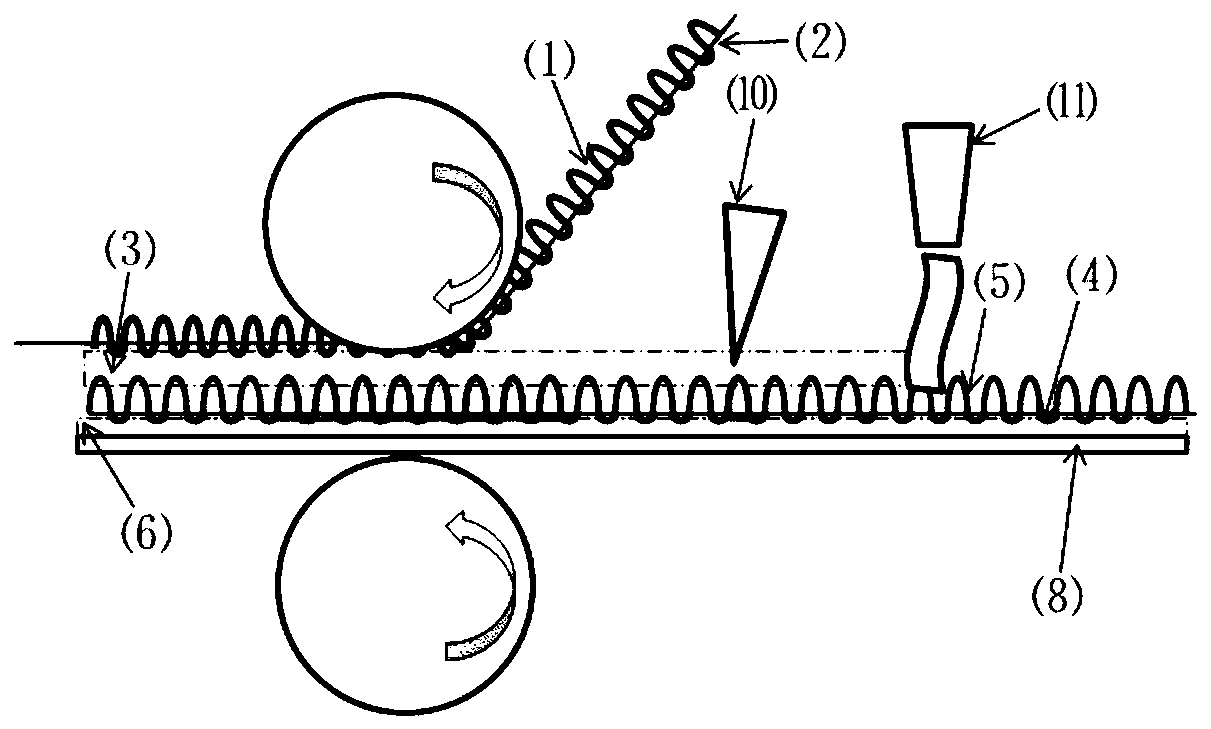

[0052] (1) Carpet fiber tufting

[0053] Nylon fibers are tufted on the first long-fiber non-woven fabric by tufting carpet weaving machine equipment to form a carpet fiber layer, and rolled into rolls for later use. The piled side of the carpet fiber layer is the carpet pile, and the other side is the tufted back, which is to be pre-coated with latex.

[0054] (2) Latex pre-coating and drying

[0055] Water-based environmentally friendly latex SBR is used, and the ratio is SBR: antibacterial agent: calcium carbonate: foaming agent = 62-100: 0-1:0-35: 0-2, preferably 65-70: 0-1: 28-35: 0 to 1, wherein the content of antibacterial agent and foaming agent can be 0, put the above raw materials into the mixing tank according to the proportion, after stirring evenly, use a foaming machine to carry out air foaming, the f...

Embodiment 2

[0064] Embodiment 2: Resilience ratio of wheelchair experiment

[0065] The size of the finished square blanket is 500mm*500mm, and the thickness of the sample is measured with a thickness gauge, and the valid data is recorded. Place the measured carpet on the bottom plate of the wheelchair tester to fix it, place the simulated wheelchair foot with a load of 90kg on the carpet surface, set the number of rotations to 2000 revolutions, and start the instrument. After the rotation, take out the sample blanket and place it horizontally for 24 hours. After the above steps are completed, use the thickness gauge again to measure the full thickness of the sample to obtain valid data. Calculate the resilience ratio after comparing the valid data.

[0066] The soft-bottom carpet of recycled yarn and the recycled yarn soft-bottom carpet without non-essential structure are manufactured with reference to the method of embodiment 1.

[0067] Conclusion: The higher the percentage, the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com