A data filtering method of steel bite impact based on working condition signal triggering

A technology of signal triggering and impact data, which is applied in the direction of manufacturing tools, metal processing equipment, and roll safety equipment, can solve the problems of uncertain frequency components of vibration data, screening out steel-biting impact data, and large differences in impact vibration data. Achieve the effect of accurate early warning, avoid abnormal downtime and major economic losses, and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

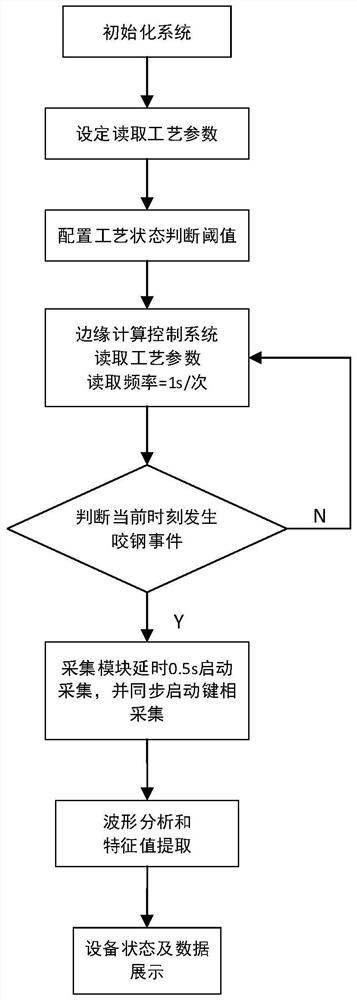

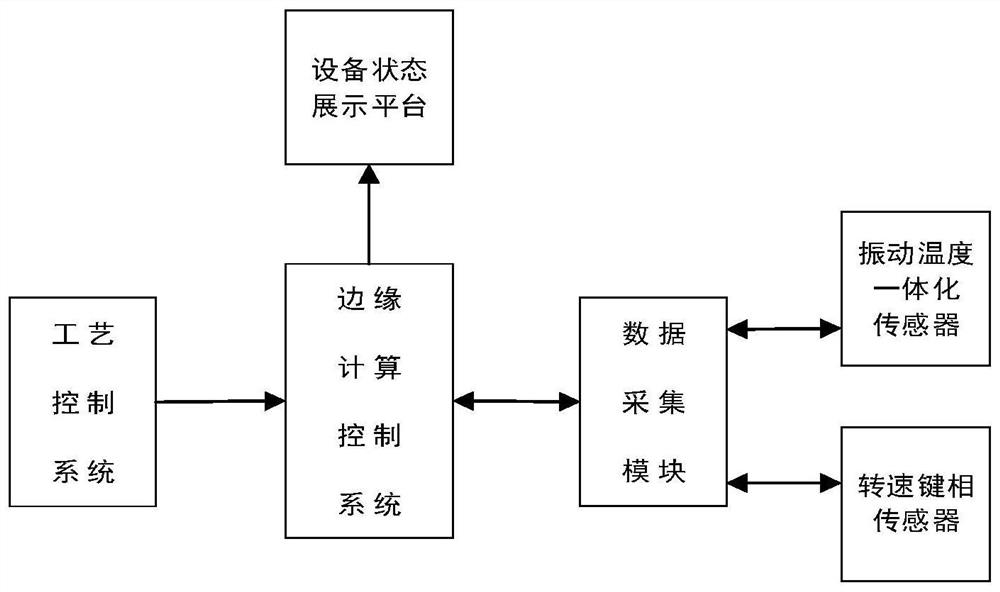

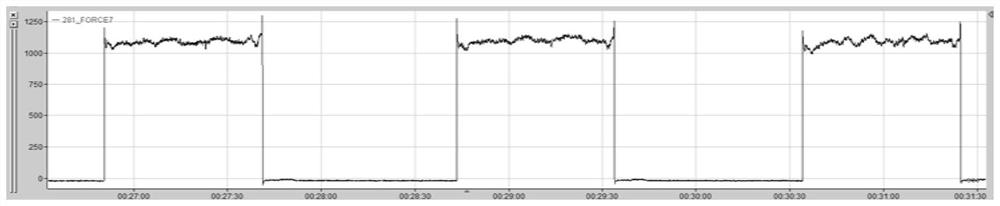

[0029] see Figure 1 to Figure 6 , a method for filtering steel-biting impact data triggered by a working condition signal, comprising the following steps:

[0030] Step 1, rationally select the real-time working condition data of the production line as the working condition judgment parameter of the real-time process state of the rolling mill;

[0031] Step 2, combining the actual operating conditions and working conditions of the production line, configure the process judgment threshold of the working condition judgment parameters;

[0032] Step 3, the edge computing control system reads the working condition judgment parameters in real time, and through logical judgment, it is determined that a steel biting event has occurred in the rolling mill at the current moment;

[0033] Step 4, when it is judged that a steel biting event occurs, the edge computing control system delays triggering the corresponding sensor channel of the vibration acquisition module to collect vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com